Table 2.

Research paper characteristics related to the free convection heat transfer.

| Ref | Geometry Description | Nanofluid | Methodology | Results | Decision Variables |

|---|---|---|---|---|---|

| [15] | Inclined, porous, semi-annulus enclosure | Magnetic Fe3O4 -water | Free convection, Buongiorno and Darcy models, FVM, SIMPLE |

- Adding nanoparticle volume fraction → Nu increases - Increase in porosity number → Nu increases |

10 ≤ Ra ≤ 1000 Porosity number = 0.4, 0.7 0 ≤ ≤ 0.04 0 ≤ inclination angle of cavity ≤ 90 |

| [16] | Square enclosure and convection around a circular cylinder, different geometries of cylinders | Ag-water | Free convection, Darcy–Brinkman model |

- Porous layer thickness increases (20% to 80%) → free convection performance decreases (up to 50%) | 103 < Ra < 106 10−5 < Da < 10−1 0% < thickness of porous layer < 100% 1 < thermal conductivity ratio 0 < < 0.1 |

| [17] | Square enclosure | MWCNT–Fe3O4/water | Free convective MHD, MRT, Lattice–Boltzmann |

- Increase in Ra → increase in heat transfer rate - Increase in Ha → decrease in Ra - Increase in Nu (+4.9%) |

10−2 < Da < 10−1; 103 < Ra < 105; 0.4 < porosity < 0.9; 0 < < 0.003; 0 < Ha < 50; |

| [18] | Inclined square enclosure and exothermic chemical reaction administered by Arrhenius kinetics | Tilted nanofluid | Free convective Buongiorno nanofluid model, FEM |

- Re increases → Nu decreases | Dissemination of streamlines; isotherms; iso-concentrations; and average Nusselt number |

| [19] | Square cavity and linearly heated left wall with composite nanofluid–porous layers | Cu-water | Free convection, Galerkin finite element method, Darcy–Brinkmann model |

- Increase in Ra → intense streamlines |

= 0.1; 10−7 ≤ Da ≤ 1; 103 ≤ Ra ≤ 107 |

| [20] | Inverse T-shaped cavity | MWCNT–Fe3O4/water | Free convection MHD, extended Darcy–Brinkman–Forchheimer model |

- Lower inclination angle → higher Nu - Lower values of ratio of dimensionless convection coefficient and the magnetic field viscosity parameter → significant heat transfer enhancement |

0 ≤ magnetic field viscosity parameter ≤ 1; 0.7 ≤ porosity ratio ≤ 1.4; 0 ≤ magnetic field inclination angle ≤ 0 ≤ ratio of dimensionless convection coefficient ≤ 10; Ha = 20; Ra = 105 |

| [21] | Square cavity and two semicircular heat sources in the wall | MWCNT–Fe3O4/water | Free convection, FEM |

- Ra = 1 × 104 → Nu increases with magnetic number | 100 < Magnetic number < 5000; 0.2 < Strength ratio of magnetic sources < 5; 0 < Ha < 50; 0.1 < porosity coefficient < 9 |

| [22] |

|

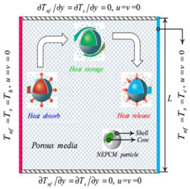

Nano-Encapsulated Phase Change Materials (NEPCM) |

Free convection. local thermal non-equilibrium (LTNE) |

- Increase in thermal conductivity of porous medium → and increase in heat transfer | 0 ≤ ≤ 0.05 |

| [23] | Transient natural convection and a square cavity, considering nanoparticle sedimentation | Al2O3/water | Free convection | - Nu decreased - Reduction in convection heat transfer |

104 < Ra < 107; 10−5 < Da < 10−2 |

| [24] | Square cavity | Ag–MgO/water | Free convection, LTNE, Darcy model, Galerkin FEM |

- Increase in Ra→ increase in the vortex’s strength - Increase in heat transfer (5.85 times) |

10 ≤ Ra ≤ 1000; 0.1 ≤ ε≤0.9; 0 ≤ φ ≤ 0.02; 1 ≤ H ≤ 1000 |

| [25] | Inclined enclosure with wavy walls and partially layered porous medium | Cu-Al2O3 water | Free convection, Galerkin FEM, Darcy–Brinkman model |

- Increase in heat transfer | 0 < inclination angle < 90; 104 ≤ Ra ≤ 107; 10−2 ≤ Da ≤ 10−5; 0.2 ≤ porous layer width ≤ 0.8; 1 ≤ number of undulations ≤ 4; 0 ≤ ≤ 0.2 |

| [26] | Eccentricity heat source and porous annulus | Cu-water | Free convection | - Increase in heat transfer | 0 ≤ ϕ ≤ 0.04; 103 ≤ Ra ≤ 106; 10−4 ≤ Da ≤ 10−1; |

| [27] | Transient natural convection and non-Darcy porous cavity with an inner solid body | Al2O3 -Water | Free convection, Buongiorno model, Brinkman–Forchheimer extended Darcy formulation. FDM |

- Higher Da→ uniform nanoparticle distribution - Increasing porosity → uniform nanoparticle distribution - Maximum Nu enhancement is approximately 30% |

The porosity of the porous medium; Darcy number; The nanoparticles’ average volume fraction |

| [28] | Inner corrugated cylinders inside wavy enclosure and porous–nanofluid layers | Ag nanofluid | Free convection | - Increase in Ra and Da → increase in fluid flow strength and shear layer thickness - Increase in porous layer thickness→ decrease in heat transfer |

106 ≥ Ra ≥ 103; 0.1 ≥ Da ≥ 0.00001; 0.2 ≥ vertical location (H) ≥ −0.2; 6 ≥ number of sinusoidal inners; cylinders (N) ≥ 3 |

| [29] | Inverse T-shaped cavity and trapezoidal heat source in the wall | Fe3O4- water |

Free convection, magnetic field dependent (MFD), FEM |

- Local and average Nu increased | Darcy, Hartmann, and Rayleigh numbers; inclination angle; cavity aspect ratio |

| [30] | Spherical electronic device | Cu-water | Free convection, SIMPLE algorithm |

- Heat transfer increases - Average Nu increases |

6.5 × 106 < Ra < 1.32 × 109; 0 < < 10%; 0 < thermal conductivity of the porous material’s matrix < 40 |

| [31] | Tilted hemispherical enclosure | Water-ZnO | Free convection experiment |

Increase in heat transfer | 0 < inclination angle < 90; 0 < < 8.22% |

| [32] | Wavy-walled porous cavity and inner solid cylinder | Al2O3/water | Free convection, FEM, Forchheimer–Brinkman extended Darcy model, Boussinesq approximation |

- Higher values of Da → heat transfer enhancement | 0 ≤ ≤ 0.04; 10−6 < Da < 10−2; 0.2 ≤ ε ≤ 0.8 |

| [33] | Partitioned porous cavity for application in solar power plants | MWCNT–Fe3O4/water | Free convection, CFD method, volume averaging the microscopic equations |

- Increase in Da, Ra → Nuave increases | 103 < Ra < 106; 0.5< porosity coefficient ratio < 1.8; 0 < < 0.003; 0.1 < Ri < 20; 0.01 < Da < 100; Thermal conductivity ratio = 0.2, 0.4, 1, 5 |

| [34] | Square cavity and inner sinusoidal vertical interface | Ag/water | Free convection, Galerkin FEM |

- Increase in Da, Pr → Nuave increases | 0.6 < power law index < 1.4; 10−5 < Da < 10−1; 0 < < 0.2; 1 < undulation number (N) < 4; 0.015 < Pr < 13.4; Ra = 105 |

| [35] | Hot rectangular cylinder and cold circular cylinder | copper–water | Free convection, Brinkman-extended Darcy model, Brinkman correlation |

- Heat transfer enhanced | Rayleigh number; Hartmann number; Darcy number; magnetic field inclination angle; nanoparticles volume fraction; nanoparticles shape factor; nanoparticles material; nanofluid thermal conductivity; dynamic viscosity models; nanofluid electrical conductivity correlation on streamlines; isotherms; local and average Nusselt numbers |

| [36] | Partially heated enclosure | Al2O3/water | Free convection, FEM, Brinkman equation |

- Heat transfer rate augmented - Ra, Da increases → average velocity |

103 < Ra < 106; 0 < < 5%; 0 < Ha < 100; 0.001 < Da < 1 |

| [37] | I -shaped cavity | Cu–water | Free convection, MHD, FDM |

- Ha increases → Nu decreases - Ra increases → Nu increases - Maximum Nu occurs at B = 0.2 - Minimum Nu occurs at B = 0.8 |

Ha; nanofluid volume fraction; heat source size; location and angle of magnetic field on heat transfer; entropy generation; thermal performance |

| [38] | Porous enclosure | Cu, Al2O3 and TiO2/water | Free convection, MHD |

- Increase in magnetic field intensity→ heat transfer deterioration - Enlarging nanoparticles, denser nanoparticles→ heat transfer deterioration |

0 ≤ Ha ≤ 50; Nanoparticle volume fraction; Nanoparticle diameter |

| [39] | Inclined cavity | Al2O3- water |

Free convection Entropy generation |

- Increase in chamber angle → increase in heat transfer - Adding nanoparticle volume fraction → increase in heat transfer |

Rayleigh number Hartmann number; magnetic field angle changes; chamber angle changes; entropy parameter; radiation parameter; volume percent of nanoparticles |

| [40] | Cubical electronic component and hemispherical cavity | Water-ZnO | Free convection, control volume method |

- Inclination increases → Nuava decreases - Nanofluid concentration increases → heat transfer increases |

0 < volume fraction < 10%; Nuave |

| [41] | Inverted T-shape | MWCNT–Fe3O4/water | Free convection, thermal transmission |

- Ha increases → Nuave decreases | Heat transfer performance; flow structures |

| [42] | Inverse T-shaped cavity and trapezoidal heat source in wall with wavy Wall | Magnetic Al2O3/water | Free convection, FEM, Koo–Kleinstreuer–Li (KKL) correlations |

- Increase in Ra, decrease in Ha → increase in flow intensity - |

Heat generation parameter; the shape factor of nanoparticles; Hartmann number; nanoparticle concentration; displacement of the trapezoidal heater wall; Rayleigh number; the amplitude of wavy wall |