Table 4.

Research paper characteristics related to the mixed convection heat transfer.

| Ref | Geometry Description | Nanofluid | Methodology | Results | Decision Variables |

|---|---|---|---|---|---|

| [53] | Inclined flat plate | Water-Cu | Mixed convection, MHD, DQM |

Nu reduced | Ra = 105; Ha = 25 |

| [54] | Lid-driven enclosure and two adherent porous blocks | Alumina/water | Mixed convection | -Ri < 1 → heat transfer enhancement - Ri ≥ 1 → reduction in heat transfer |

0.01 ≤ Ri ≤ 10; 0 ≤ ≤ 0.04 |

| [55] | Rotating circular cylinder and trapezoidal enclosure | Cu- water |

Mixed convection, MHD |

- Decrease in stream function values → vertical magnetic field - Increase in Ha → increase in Nuave - Increase in Ha, thermal conductivity rate, cylinder radius, Da → increase in Nuave - Decrease in Ri → increase in Nuave |

0 < Ha < 100; 1 < Thermal conductivity ratio < 10; −5 < angular rotational velocity < 5; 0.01 < Ri < 100; 0 < Inclination angle < 90; 0.2 < Cylinder radius < 0.4; 10−5 < Da < 10−1; 0 < nanofluid concentration < 0.1 |

| [56] | Square cavity with inlet and outlet ports | Water-based nanofluid | Mixed convection, Brownian diffusion, thermophoresis, FDM |

- Increase in Re → cooling improvement - Ra = 10 → Nu = 1.071 - Ra = 100 → Nu = 3.104 - Ra = 1000 → Nu = 13.839 - Ra = 10000 → Nu = 49.253 - - |

104 < Ra < 106; Pr = 6.82; 10−5 < Da < 10−6; 50 < Re < 300; ε = 0.5; Le = 1000 |

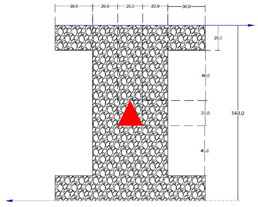

| [57] | H-shaped cavity with cooler and heater cylinders | Cu-water | Mixed convection, Boussinesq approximation |

- Increase in AR → decrease in heat transfer rate increase in Da, decrease in Ri → increase in heat transfer rate |

10−4 ≤ Da ≤ 10−2; 1 ≤ Ri ≤ 100; 1.4 ≤ AR ≤ 1.6; |

| [58] | Trapezoidal chamber | Cu-Al2O3/ water |

Mixed convection, FDM |

- Increase in Re → increase in energy transport and convective circulation - Increase in Da → heat transfer enhancement |

Reynolds number; Darcy number; nanoparticle volume fraction |

| [59] | Inclined cavity | Cu-water | Mixed convection, Darcy–Brinkman–Forchheimer model, SIMPLE algorithm |

- Heat transfer rate increases with increasing Da. | |

| [60] | Lid-driven square cavity | Al2O3/water | Mixed convection | - Decrease in Ri → increase in momentum - Ri = 100 → decrease in Darcy effects - Changing nanoparticles volume fraction and Da → significant changes in streamlined pattern - Higher Ri → more buoyancy effects - Increase in Da and Ri → less fluid resistance and more momentum penetration - Increase in Da → decrease in temperature, more uniformity in heat transfer |

Ri = 0.01, 10 and 100; 10−4 ≤ Da ≤ 10−2; 0 ≤ ≤ 0.04 |

| [61] | Stretching surface | --- | Mixed convection, MHD |

- For m < 1→ increase in velocity results in an increase in thermophoresis - For m > 1→ increase in velocity results in a decrease in thermophoresis. |

Effects of buoyancy parameter; magnetic parameter; Brownian motion; thermophoresis parameter, etc., on velocity, temperature, and nanoparticle volume fraction |

| [62] | Square cavity and two rotating cylinders | Al2O3/water | Mixed convection | - Heat transfer enhancement (+ 20.4%) | |

| [63] | Triangular shape, partitioned, lid-driven square cavity involving a porous compound | Ag–MgO/water | Mixed convection MHD |

- Nu enhancement (14.7%) | < Ri < 100; 0 < Ha < 60; 10−4 < Da < 5 × 10−2; 0 < < 0.01 |

| [64] | Vertical surface | Cu-water | Mixed convection, Laplace transform technique Crank Nicolson method |

- Increase in magnetic field strength → and decrease in fluid velocity - Porosity increases → fluid velocity decreases |

Magnetic parameter; porosity parameter; thermal and solute Grashof number; nanoparticle volume fraction parameter; time; Schmidt number; chemical reaction parameter; Prandtl number |

| [65] | Inclined cavity and porous layer | Cu-water | Mixed convection, incompressible smoothed particle hydrodynamics (ISPH) |

- Ri increases → Nuave decreases - increases → overall heat transfer increases |

0.001 < Ri < 100; 10−5 < Da < 10−2; 0 < < 0.05 |

| [66] |

|

CuO–Water | Mixed convection, entropy generation, Buongiorno’s two-phase model |

- Increase in volume concentration → increase in Nuave - Maximum enhancement in cooling performance was 17.75% |

- Volume concentration; development of a new predictive correlation |

| [67] | Gamma-shaped cavity | CuO–Water | Mixed convection, Entropy generation, FVM |

- Increase in the Nusselt number with the volume fraction is more pronounced for the smallest heat source, a heat source placed at the lowest height from the bottom side, the lowest volumetric heat generation, the lowest imposed magnetic field, the lowest Darcy number, and for a porous media with the lowest solid to fluid thermal conductivity ratio. Increasing the nanoparticle volume fraction has a higher impact on the production of entropy than the enhancement in the heat transfer rate. |

- Hartmann number; nanoparticle volume fraction; the length and location of a heat source |

| [68] | Rotating triangle chamber | Graphene Oxide generalized hybrid | Mixed convection utilizing bvp4c solver |

The velocity upsurges due to the dimensionless radius of the slender body parameter in case of the assisting flow. | 0.025 ≤ ≤ 0.035 |