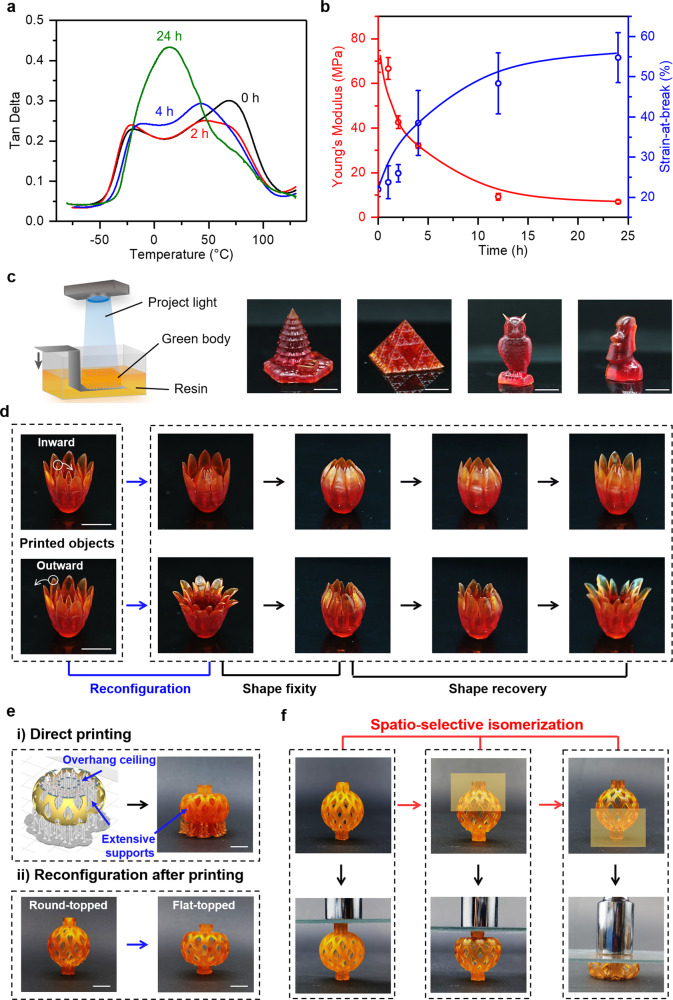

Fig. 4. Shape and mechanical reprogrammability for digital light 3D printed HUBM-co-PPGA.

a Evolution of thermal transitions upon annealing at 120 °C. b Evolution of mechanical properties upon annealing at 120 °C. c Schematic illustration of the printing process and photos of the 3D printed objects. d Permanent shape reconfiguration with the printed flower petals being permanently deformed inward or outward (80 °C, 60 min) and their corresponding shape memory behaviors with shape fixing and recovery at −40 °C and 60 °C. e The construction of the flat-topped lantern structure via (i) direct printing and (ii) reconfiguration after printing. f Spatio-selective isomerization of the printed lantern structure and the corresponding compression behaviors under the same load. (The yellow regions were immersed in a heated oil bath at a temperature of 120 °C for 6 h). Scale bar, 10 mm.