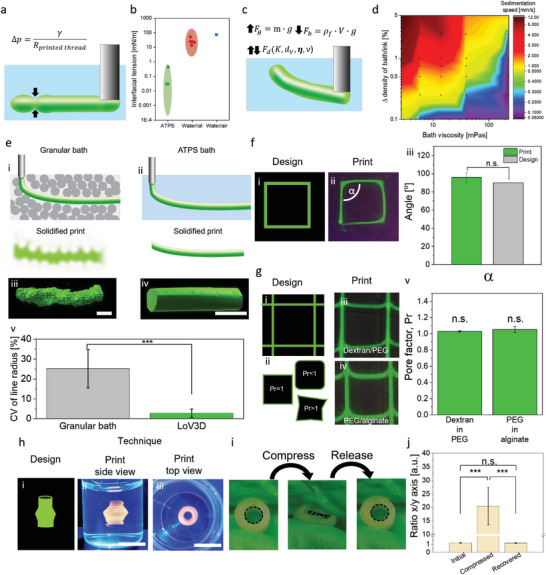

Figure 2.

Physical parameters influencing ATPS print stability. a) Schematic depiction of droplet breakup induced by the Laplace pressure difference between bath and ink. b) Comparison of interfacial tension of liquid/liquid ATPS (green), water/oil (red) systems, and the water/air system.[ 36 , 37 , 38 , 39 ] c) Forces influencing the strand position and stability, which includes: gravitational force F g influenced by the mass m of the solution as well as the gravitation acceleration g. Buoyancy F b is influenced by the density of the matrix ρ f, volume of the ink V, and gravitation constant g. Drag force F d is influenced by the drag coefficient K, the volumetric dimensions of the deposited ink d v, bath viscosity 𝜼, and velocity ν. d) Sedimentation speed of a PEG droplet within a dextran bath with varying density mismatch and bath viscosity (N = 3). e) Comparison of low viscous ink behavior within i) granular embedding bath or ii) all‐aqueous LoV3D embedding bath. 3D reconstructions from confocal images of 5% w/w Dex‐TA (dextran‐tyramine) strands printed in iii) granular or iv) all‐aqueous LoV3D bath composed of 11.13% w/w PEG v) which were analyzed in the context of coefficient of variation (CV) of the strand radius, showing a significantly smoother strand when printed in all aqueous LoV3D surrounding (N ≥ 4). f) Single line fidelity assessment by comparing i) design with ii) print of fluorescently labeled dextran in PEG using fluorescent microscopy. iii) The angles (α) obtained showed no significant difference from the initial design (N = 4). g) Grid pore fidelity assessment by comparing i) design utilizing the ii) pore factor as a measure. iii,iv) Fluorescent micrographs of printed grids with dextran in PEG and PEG in alginate, respectively. v) Pore factor analysis of the obtained grids shows no significant differences between both ink/bath combinations and the design (N = 3). h) Printed 3D structure created with PEG as ink within an alginate bath based on i) 3D design. ii) Side view and iii) top view photographs of the created print within the bath. i) Photographs of a crosslinked and from the bath extracted 3D construct that was mechanically deformed using cyclical compression. j) Quantitative image analysis of the aspect ratio of channel cores before, during, and after compression (N = 3). Scale bars: e, iii, iv) 500 µm, h) ii,iii) 5 mm. Significance is indicated with *** p < 0.005 and n.s for p > 0.05, one‐way ANOVA with Tukey post hoc test.