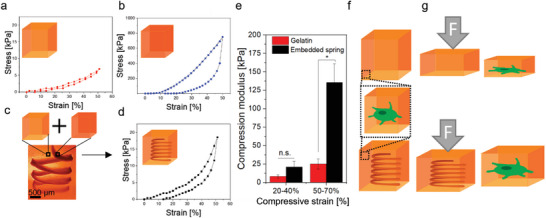

Figure 4.

Printing mechanical hydrogel springs in hydrogel constructs using LoV3D allows for uncoupling the mechanical properties of the cellular level and the tissue level. Stress‐strain curves obtained from compression tests of a) gelatin bulk, b) PEGDMA and alginate bulk, or c,d) gelatin bulk containing a spring of PEGDMA and alginate. e) Compression moduli calculated in a low strain (20–40%) regime and high strain (50–70%) regime of the pure gelatin bulk (red) as well as with a PEGDMA alginate spiral printed within the bulk. f) Illustration indicating that incorporated cells within the gelatin, as well as the composite, would on the micro level only be surrounded by gelatin. g) Schematic illustration that traumatic external forces can potentially be counteracted by the printed internal hydrogel spring, which mechanically protects both cells and constructs. Significance is indicated with * p < 0.05 and n.s. p > 0.05, 1‐way ANOVA with Tukey post hoc test.