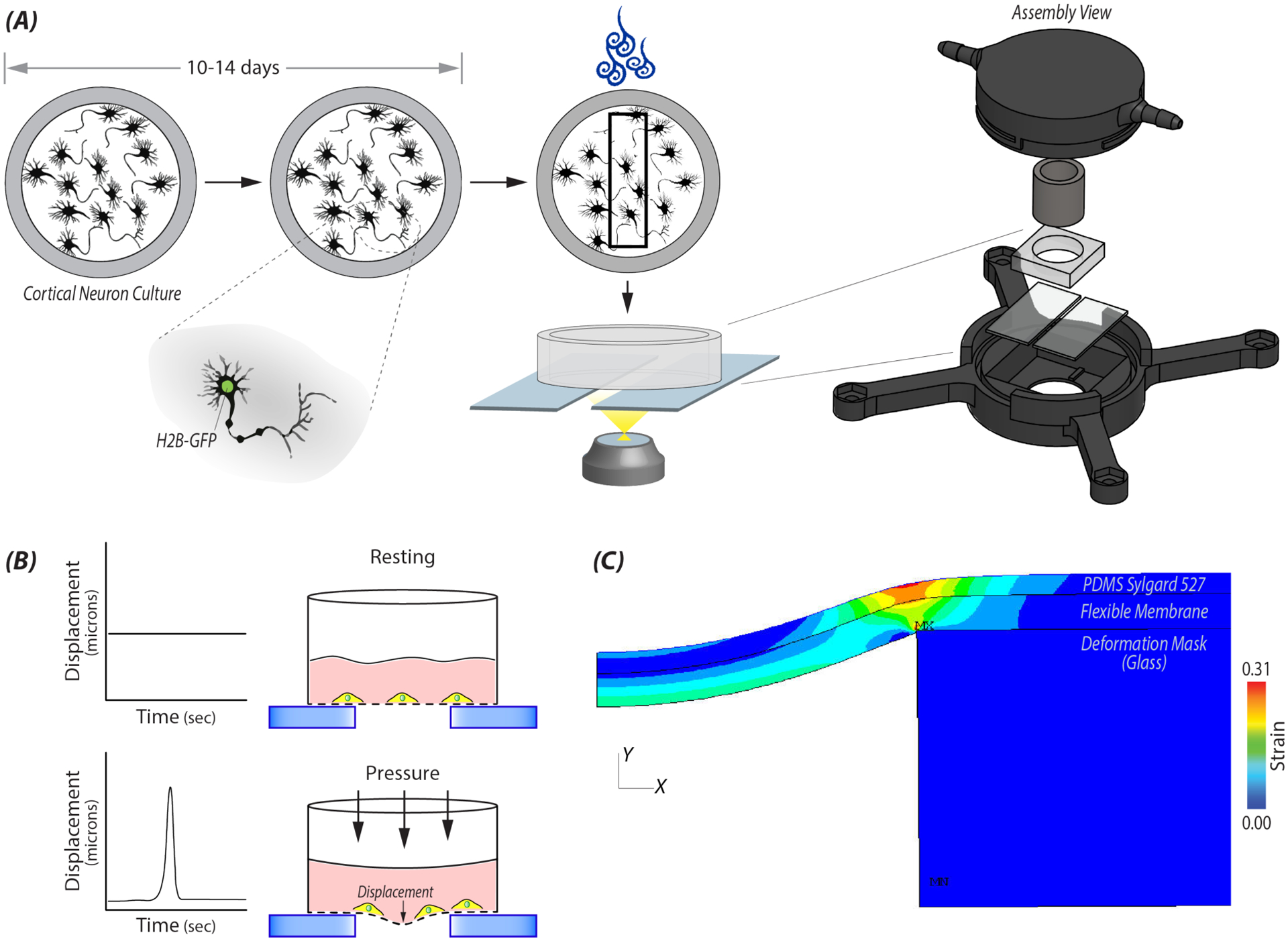

Figure 1: A custom device was designed for controlled mechanical stretch of primary neural cultures.

A) Custom machine wells constructed out of PEEK or PS were used to culture primary embryonic (E18.5) cortical neural cultures from H2B-eGFP mice. On days 10–14, a single well was added into a 3D printed pressure chamber that attached to the automatic stage of a Nikon A1R confocal. Within a given location of a well, 20 cells were selected and imaged at selected time steps before and after applying a high intensity load. B) Cartoon depicting the displacement of the flexible membrane and in turn the neural cells adherent to the membrane, during the high impulse load. C) Finite element analysis (FE) model was used to determine strain and rate of strain at a specified locations in the well during a 500ms impulse from the electro-pneumatic device. During the impulse, the flexible elastic membrane on which the cells were plated deformed into a 2mm gap between two glasses slides. Cells within the specified location received uniaxial stretch.