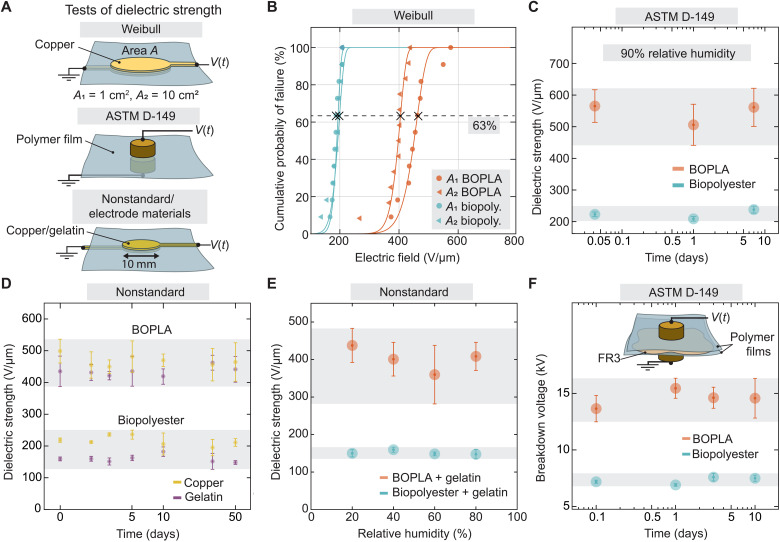

Fig. 3. Evaluation of dielectric strength of BOPLA and biopolyester films.

(A) Experimental setups to test dielectric strength included: (top) circular evaporated copper electrodes used for Weibull tests, (middle) standard ASTM D-149 cylindrical brass electrodes, and (bottom) nonstandard 10-mm-diameter circular electrodes made from NaCl-infused gelatin hydrogel or evaporated copper as reference material. (B) Weibull distribution for BOPLA and biopolyester films with circular copper electrodes with areas A1 = 1 cm2 and A2 = 10 cm2. (C) Dielectric strength of BOPLA and biopolyester exposed to 90% relative humidity over the course of 10 days. (D) Dielectric strength of BOPLA and biopolyester using copper and hydrogel electrodes and stored under ambient conditions was tested between 0 and 50 days after fabrication. Consult table S2 for additional details. (E) Dielectric strength of BOPLA and biopolyester films with gelatin hydrogel electrodes, exposed to 20, 40, 60, or 80% relative humidity for 1 day. (F) Standardized breakdown tests performed across two films separated by a thin layer (0.05 ml) of FR3 under ambient conditions.