Abstract

The upgrade and development of manufacturing industry makes predictive maintenance more and more important, but the traditional predictive maintenance can not meet the development needs in many cases. In recent years, predictive maintenance based on digital twin has become a research hotspot in the manufacturing industry field. Firstly, this paper introduces the general methods of digital twin technology and predictive maintenance technology, analyzes the gap between them, and points out the importance of using digital twin technology to realize predictive maintenance. Secondly, this paper introduces the predictive maintenance method based on digital twin (PdMDT), introduces its characteristics, and gives its differences from traditional predictive maintenance. Thirdly, this paper introduces the application of this method in intelligent manufacturing, power industry, construction industry, aerospace industry, shipbuilding industry, and summarizes the latest development in these fields. Finally, the PdMDT puts forwards a reference framework in manufacturing industry, the framework describes the specific implementation process of equipment maintenance, and gives an example of industrial robot using the framework, and discusses the limitations, challenges and opportunities of the PdMDT.

Keywords: Digital twin, Predictive maintenance, Fault prediction

1. Introduction

In the manufacturing industry, equipment repair and maintenance is a very important link. The maintenance method is to regularly check the health of the equipment, repair equipment failures, and prevent secondary damage and downtime, which directly affects the operating time and work efficiency. Therefore, predictive maintenance (PdM) method is proposed.

PdM is a method of prognostics and health management (PHM), which is a technology based on historical data, mechanism models and domain knowledge. It can predict equipment trends, behavior patterns and correlations through statistics or machine learning models to predict upcoming failures or remaining useful life and other key indicators in advance, thereby improving the decision-making process of maintenance activities, reducing the hazards of failures, and avoiding the equipment shutting down ADDIN EN.CITE [. For manufacturing companies, the use of predictive maintenance technology can effectively avoid downtime, fault repair and excessive maintenance, maximize equipment running time and work efficiency; reduce maintenance costs and production losses, and improve economic benefits.

Although more and more enterprises have realized the advantages of predictive maintenance [1], few enterprises have implemented it. At present, the main maintenance modes are still post maintenance and large-scale redundant preventive maintenance [2,3]. This situation is mainly due to the lack of accuracy, reliability and adaptability of predictive maintenance [4]. Researchers are exploring appropriate methods to solve these problems. Through the analysis of technical characteristics and application cases, it is concluded that digital twin technology can help predictive maintenance break through or improve these deficiencies at the level of fault diagnosis and prediction and maintenance decision-making [[5], [6], [7]].

Digital twin is a key enabling technology, and it is the virtual representation of physical objects, processes and real-time data involved in the entire product life cycle [8]. Its concept first appeared in Greives's speech on the concept of Product Lifecycle Management (PLM) in 2002. As an evolution of PLM, Greives and Vickers redefined it in 2012 [9], defining it as the digital representation of physical assets and the automatic connection connecting them together. The digital twin has the characteristics of interactive feedback between cyberspace and physical space, data fusion and analysis, and decision-making iteration optimization. It can be applied to a variety of scenarios. In industrial manufacturing enterprises, digital twins are used to optimize the manufacturing life cycle and promote intelligent manufacturing upgrade [10], which has become a research hotspot in the area of intelligent manufacturing [11]. Driven by the needs of various industries, the latest application areas of digital twin have been extended to electric power, automobiles, medical care, ships, etc. [12].

As a digital model that integrates the material characteristics, working conditions and performance degradation law of physical entities, digital twins can realize the digital description and intelligent application service of the whole life cycle of products from concept, design, manufacturing and assembly, operation, maintenance to scrapping through real-time monitoring data, high-performance accurate simulation and high confidence simulation prediction. Intelligent application services include design optimization, operation optimization, fault prediction, fault diagnosis, etc., to meet the needs of equipment predictive maintenance and bring new development opportunities for equipment predictive maintenance technology.

This article provides a detailed description of predictive maintenance (PdMDT) based on digital twins. Specifically, the main contributions of this article are as follows:

-

-

Introduce the general methods of digital twin and predictive maintenance, define the research gap between them, and analyze the importance of PdMDT research.

-

-

Describe the unique characteristics of PdMDT, such as all-factor real-time perception capability, high-fidelity model, data fusion, and high-confidence simulation prediction.

-

-

Review the existing application areas of PdMDT, including intelligent manufacturing, power industry, construction industry, aerospace industry, and shipbuilding industry.

-

-

Through the analysis of the existing application fields and technology combination, propose the reference framework of the PdMDT system in the manufacturing industry. Including data collection layer, state judgement layer, service decision-making layer.

-

-

According to the PdMDT reference framework, an example of predictive maintenance of industrial robot is given.

-

-

Put forward the challenges faced by PdMDT and determine the future research directions. Including the need of digital twin common platform, full life cycle implementation and technology integration.

The rest of this article is organized as follows. In Section 2, we introduce the general methods of digital twin and predictive maintenance, define the research gap between them, and analyze the importance of PdMDT research. In Section 3, we describe the unique characteristics of PdMDT. Section 4 introduces the application area and application content of PdMDT. Section 5 proposes the reference framework of the PdMDT. Section 6 gives the industrial robot example of PdMDT. Section 7 discusses the limitations, challenges, and opportunities of PdMDT. We conclude the article in Section 8.

2. Digital twin and predictive maintenance

In this section, we mainly introduce the general methods of digital twin and predictive maintenance, define the research gap between the two technologies, and point out the importance of the research of the predictive maintenance method based on digital twin (PdMDT).

2.1. Digital twin method

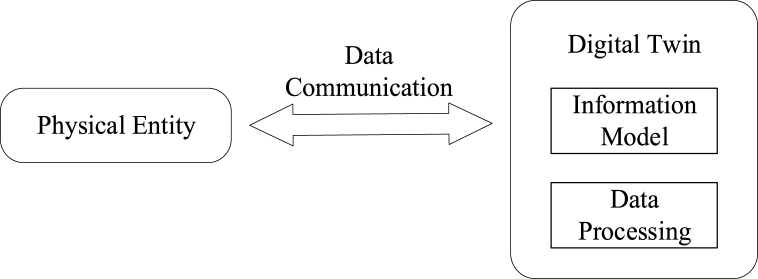

Digital twin is a process of building and managing the digital twin and its operating environment or system, which involves the whole life cycle of design, construction, operation and maintenance and scrapping. Digital twin is defined as the virtual representation of manufacturing elements in the manufacturing industry, such as the virtual representation of products, resources and processes. The digital twin is a dynamic model, which is constantly updated and changed with the changes of physical entities, and represents the equipment status, working conditions, geometry and resource status in the form of data synchronization. When building a digital twin, it generally includes the following three parts:

When constructing a digital twin, it generally includes the following parts. Lu [13] put forward three parts of digital twin in his article, namely.

-

1)

Information model of physical entity;

-

2)

Data communication mechanism between digital twins and physical entities;

-

3)

The data processing module which can extract information from heterogeneous multi-source data and build a real-time representation of physical entities; Through the cooperation of these three parts, the digital twin can operate normally. The general reference model of digital twin is shown in the following figure.

Information model: the information model of physical entity refers to abstracting the characteristics of physical entity and constructing an information model about it. Information model usually includes appearance model and mechanism model of physical entity. Without the information model to describe the features of physical entity, data transmitted to cyberspace will lose its meaning and context.

Communication mechanism: to establish digital twin, the data communication mechanism between digital entity and physical entity is the key point. In physical space, the state synchronization between digital entity and physical entity depends on two-way real-time data communication. Digital twin system senses the state parameters and performance parameters of physical entity by using high-precision information acquisition equipment (such as sensors), and realizes real-time data acquisition and transmission.

Data processing: complex system has many equipment parameters and large data redundancy, and these parameters have strong coupling, non-linearity and time variability, which directly affects the quality of data. Digital twin technology uses various data processing technologies such as big data to store, screen, process and interact with the data in real time, so as to effectively judge and process the changes of the external environment. How to apply artificial intelligence algorithm to big data analysis technology is the key to further realize big data processing and modeling.

In addition, digital twins can also include the following parts:

Platform: Digital twin simulation platform is a development platform, which is specifically realized as a software development platform integrating data management, model management, real-time calculation and data simulation prediction. Through the digital twin simulation platform, the virtual entity can quickly and accurately reflect the state of the physical entity, so as to guide the behavior of the physical entity in time and make the system control more efficient.

Visualization: Visualization technology is an effective means for people to efficiently understand information and make decisions. In the digital twin system, the three-dimensional (3D) visualization technology can give the operation and maintenance status of the system in the form of surreal, and carry out multi-scale virtual mapping for the key subsystems of the complex system, helping the personnel to quickly understand the relationship between physical entities and massive data.

2.2. Predictive maintenance method

Predictive maintenance is usually condition-based maintenance. Through regular (or continuous) condition monitoring of system components, determine the status of equipment, predict the future development trend of equipment status, and prepare predictive maintenance plans in advance according to the status development trend and possible failure modes of equipment. At present, the specific content of predictive maintenance usually includes equipment condition monitoring, fault diagnosis, residual life prediction and maintenance decision-making.

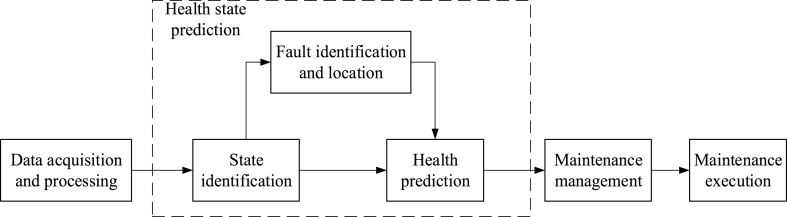

In the manufacturing field, Wang [14] put forward the system function model of predictive maintenance is as follows (Fig. 2).

Fig. 2.

The system function model of predictive maintenance.

Predictive maintenance defined by the model includes data acquisition and processing, state identification, fault identification and location, health prediction, maintenance management and maintenance execution.

Data acquisition and processing. The core equipment of data acquisition and processing is composed of sensors and data collectors. The sensor is mainly used to collect the status information and process information of the equipment and associated environment, and the data collector is mainly used to provide the process information of the equipment on the production site.

Status identification. State identification refers to the aggregation of state characterization data and threshold judgment by means of feature analysis to obtain the current state of the equipment. The identified equipment state is used as the input of state prediction to provide the basis for fault diagnosis or health prediction. Data preprocessing and feature analysis of the acquired data are required before state identification.

Fault identification and location. Fault diagnosis includes mechanism model-based method and data-driven method. The method based on mechanism model is to establish the simulation model based on the mechanical and circuit principle of the equipment itself. When the equipment fails, the residual value generated by the comparison between the output and the model based on the output under normal conditions is used to judge different fault modes and fault levels.

The data-driven method does not need to clearly understand the internal structure of the equipment, but only needs to use the input and output data collected by the system when running in the real environment as the basis for modeling, and use statistics, classification, machine learning, pattern recognition and other methods to establish the linear or nonlinear relationship between input and output. In case of equipment failure, the normal and abnormal states of the equipment can be distinguished according to the input data in the above model.

Health prediction. Health prediction is to use state parameters and characteristic signals to evaluate the health status and future change trend of equipment based on different analysis methods and prediction models, and predict the fault trend and health before its fault occurs. The health degree is usually expressed as a percentage, which can be converted to the remaining useful life on the premise of knowing the future working state of the equipment. Literature [15] systematically summarizes the application of predictive maintenance in industry 4.0, and points out that the current methods for equipment fault detection and prediction mainly include model-based algorithms and data-based algorithms. There is a specific introduction later in this article.

Maintenance management and maintenance execution. Intelligent maintenance decision. The maintenance management of intelligent manufacturing equipment is to formulate the corresponding maintenance strategy by combining the output results of health state prediction with enterprise equipment management on the basis of full consideration of safety and cost.

2.3. Analysis of the research gap between the two studies

Through the introduction of the general methods of digital twin and predictive maintenance above, this section gives an analysis of the research gap between digital twin and predictive maintenance.

From the perspective of function, traditional predictive maintenance can only be used as a computing tool to analyze equipment status, predict equipment faults and make auxiliary decisions. These functions do not consider the complex interaction and evolution mechanism of structural and physical attributes in the equipment, and can not consider the real-time changing equipment parameters when processing data. The obtained data processing results may not reflect the real data of dynamically changing physical entities, which reduces the accuracy of evaluating and predicting the health status of equipment. As a digital model integrating the material characteristics, working conditions and performance degradation law of physical entities, digital twin can realize the automatic collection and update of data once the digital twin is established through its data interaction mechanism and its data processing ability, so as to realize the digital description and data processing of the whole life cycle of equipment from operation, maintenance to scrapping.

From the perspective of application services, predictive maintenance usually analyzes the maintenance feasibility, determines the maintenance plan and resources, and gives the specific implementation plan of maintenance activities according to the results of condition monitoring, fault diagnosis and condition prediction. This process is mostly manual. Digital twin can provide users with intelligent application services. Intelligent application services include design optimization, operation optimization, fault prediction, fault diagnosis, etc., which are sufficient to perform the data processing required for predictive maintenance. Digital twin has the ability to globally optimize maintenance decisions, and the selection of maintenance timing does not need manual judgment.

From the perspective of visualization, the traditional predictive maintenance cannot have a clear understanding of the real-time state and real-time parameters of the equipment through condition monitoring. The visual fault information of predictive maintenance is limited, and the staff can not obtain complete fault information. The digital twin display the virtual visualization model of the equipment through the visualization interface. The model interacts with the real-time data of the physical entities of the equipment, and can clearly and intuitively display the real-time status and fault information of the equipment to the operators. The various requirements such as fault warning and maintenance decision-making will also become very clear and reliable.

To sum up, when faced with equipment failure, predictive maintenance emphasizes the analysis of equipment status, prediction of equipment failure and auxiliary decision-making. Enough practical cases show that traditional predictive maintenance can only describe the dynamic process under a certain spatial scale and time scale, and can not carry out long-term dynamic maintenance. Digital twin emphasizes the state simulation of equipment. The digital twin simulates when the equipment is running, collects the equipment data that changes dynamically with time, and can provide a more intelligent service application than predictive maintenance, which can realize the long-term dynamic maintenance of the equipment. It can be said that the core idea of digital twin promotes the evolution of predictive maintenance mode.

2.4. Importance of PdMDT

Through the analysis of predictive maintenance and digital twin gaps in the previous section, this section will explain the importance of using digital twin technology to achieve predictive maintenance in combination with these gaps.

The importance of predictive maintenance for manufacturing and other industries has been widely recognized. At the same time, it is also the key to ensure that equipment maintains efficient and sustainable services. However, due to the shortcomings of predictive maintenance, there are not many enterprises [1]. At present, the main maintenance modes are still post maintenance and large-scale redundant preventive maintenance [2,3]. At the same time, the rise of digital twin technology is also a new opportunity for traditional industries and the new trend of mutual integration of technologies in different industries. Digital twin has made enough attempts in the industry. Since 2004, many large companies in the industry have begun to use digital twin technology to make many useful attempts in product design, manufacturing, service and other aspects. The combination of digital twin and predictive maintenance is also a new trend rising in recent years. The use of digital twin technology can well solve the shortage of predictive maintenance.

Nowadays, the requirements for the work continuity of industrial equipment are higher and higher. Sudden failure shutdown will affect production continuity and reduce production efficiency. From the perspective of economic benefits, the post fault maintenance and regular maintenance in the traditional maintenance mode will affect production efficiency and product quality, and greatly increase the cost of manufacturers. Compared with the traditional maintenance mode, predictive maintenance can improve the performance through the improvement of equipment availability and quality, prolong the service life of equipment, and reduce the difficulty of service support and maintenance cost.

Combined with the predictive maintenance mode of digital twin, due to the characteristics of digital twin, once the digital twin is constructed, it can realize the real-time monitoring and fault real-time prediction of equipment. There is no need for special fault detection and prediction of equipment, which does not affect the production and work efficiency of equipment, and greatly saves the labor cost and maintenance cost of equipment.

Based on the digital twin of predictive maintenance, the real-time status information and relevant technical parameters of the equipment are obtained through the data interaction mechanism, and the equipment is operated and maintained throughout the cycle in combination with the equipment operation and maintenance environment and maintenance resources.

3. Characterizing PdMDT

In this section, we first describe the unique characteristics of predictive maintenance method based on digital twin (PdMDT), and then sort out the difference between PdMDT and traditional predictive maintenance.

3.1. Real time perception

Real time perception is the basis of constructing the digital twin model of equipment. Compared with traditional predictive maintenance, the key difference of PdMDT is that it has the ability of real-time perception, real-time regulation and real-time prediction. Specifically, the construction of virtual digital twins provides many advantages for PdMDT.

3.1.1. High real-time data interaction

High real-time data interaction is the realization result of data communication mechanism in the digital twin system. As the basis of two-way interaction between physical entities and virtual entities, high real-time data interaction is applied in the whole process of equipment operation. It includes equipment data collection and monitoring, equipment health analysis, fault diagnosis, equipment behavior control, equipment life prediction and visualization technology.

High real-time data interaction is used to solve the problem of incomplete data utilization in traditional predictive maintenance. Although the traditional predictive maintenance mode based on data analysis can realize the quantitative analysis of monitoring data, there are still a large number of equipment online status data, environmental parameters and equipment history records not used in the analysis process, and the data analysis means are too single, resulting in the analysis process facing specific eigenvalues and one-sided prediction results. With the help of high real-time data interaction ability, all data can be effectively used to improve the prediction accuracy. Cattaneo [16] relies on the combination of real-time monitoring and simulation to realize the random coefficient statistical method through the exponential degradation model. Finally, it is proved that the prediction accuracy can be improved through the real-time monitoring data.

High real-time data interaction is also expected to solve the problem of data shortage in enterprises. At present, the equipment fault history data and historical status data of a single enterprise are usually insufficient. For complex equipment, such deficiencies seriously affect the accuracy of fault diagnosis and life prediction. With the data interaction ability of digital twins, enterprises can share fault data. Enterprises with similar equipment can form an information sharing network to solve the problem of insufficient maintenance data of the same equipment and improve the accuracy of equipment maintenance [17].

In addition, the traditional fault prediction method is to select the maintenance service time according to the equipment operation plan and the results of fault prediction. The selected time node is subjective and needs to rely on the experience of experts. The continuous change of equipment will also make it difficult to obtain dynamic sensing data, it needs a long time, and limits the maintenance efficiency. PdMDT can accurately obtain the dynamic sensing data, evaluate the equipment operation status according to the real-time data, and select the maintenance time through real-time analysis to prevent the failure of maintenance behavior.

3.1.2. All factors real-time perception

All factors real-time perception is also the data interaction between digital twins and physical entities. Different from the focus of high real-time data interaction, the key to all factors real-time perception is that data collection is oriented to all factors and multi types of data. Digital twins can perceive various types in real time, and the data sources cover equipment data, application data, historical data, status, etc.

All factors real-time perception ability is conducive to obtain more accurate maintenance resource requirements of equipment, and strengthen the global integration optimization ability and dynamic adaptability of maintenance decision-making. Villa et al. [18] propose a digital framework based on the Internet of things and BIM platform. It applies the sensors in the building system and the Internet of things technology on the cloud platform to sense the faults in operations in real time, so that facility managers can make decisions faster and better. Jianping Huang [19] developed an intelligent power system, which uses situational awareness and virtual reasoning to solve uncertainty and error-related problems in the application of power industry through real-time interaction between virtual and real space.

In this all factors real-time perception environment, the optimization of energy consumption and carbon emission in the maintenance process can also be realized. Lin et al. [20] propose a digital twin system architecture. The system can identify patterns through data analysis to perform predictive maintenance and effectively reduce system energy consumption.

3.1.3. Intelligent decision-making ability

In addition to the ability of data interaction, the introduction of digital twin also increases the ability of intelligent decision-making for the maintenance process.

In the real-time data interaction environment, digital twins can quickly monitor and judge the current equipment status according to the historical and current collected data, predict the future behavior of physical equipment in the simulation environment, and make intelligent optimization decision calculation [21]. With the exact fault threshold of the equipment, the independent decision-making of the equipment system can be set in the simulation environment, and the intelligent decision-making can be realized by predicting according to the real-time data. Villa et al. [18] use three-dimensional visualization technology to realize indoor intelligent monitoring by analyzing indoor conditions of buildings, enabling staff to make decisions and optimize in time.Khajavi et al. [22] use digital twin to provide users with better sauna conditions and a decision support system for sauna managers.

3.1.4. Multiple application scenarios real-time simulation

In the environment of real-time data interaction, predictive maintenance under digital twin can be applied to various application scenarios. Manufacturing, aerospace, electric power, shipping and other industries can achieve corresponding maintenance.

Manufacturing scene has always been a hot research field of digital twins, such as workshop, assembly line, mechanical equipment, etc. The realization of digital twin in the manufacturing scenario can improve the efficiency of equipment and reduce the economic and human losses of equipment failure. Guo et al. [23] constructs the digital twin model of the workshop with the help of real-time perception information. Through the digital twin model, the residual service life prediction model based on nonlinear drift Brownian motion is constructed, and the residual service life of the components is predicted, and the maintenance decision scheme is given according to the prediction. Literature [24] detects structural cracks and predicts crack growth through real-time monitoring of the operation status of offshore wind turbine support structures, so as to predict future risks and maintain them; Lu et al. [25] processed data through algorithm analysis and empirical evaluation, and used this method for predictive maintenance of constant velocity universal joints. More application scenarios are described in detail in Section 4.

3.2. High-fidelity model

High-fidelity model is the data preparation for building digital twin model of equipment Excellent high fidelity models can make the simulation results closer to the behavior of real devices.

3.2.1. High fidelity virtual model

Due to the limitations of complex environment and sensing technology, there are often perception difficulties, resulting in poor fidelity of the model in traditional predictive maintenance. In contrast, the high fidelity virtual model integrated by digital twin technology can not only reflect the geometric characteristics of physical entities, but also reflect its physical characteristics (such as electrical characteristics), interaction and evolution mechanism [12].

A very important added value of the high fidelity virtual model is that it can be simulated on the virtual model, and even the corresponding operating environment models can be combined in the simulation process [26], so as to collect the component degradation of physical equipment that cannot be collected by traditional predictive maintenance. This method also avoids the detection of production interruption equipment. Aivaliotis et al. [27] model in a digital environment that simulates real machine behavior. The machine controller and external sensors are used to collect data and synchronously adjust the digital model and its simulation. By running the ultra-high fidelity model in virtual space, the diagnostic model based on deep neural network (DNN) will be fully trained, Xu et al. [28] can find the potential problems not considered in the design.

Run an ultra-high-fidelity model in a virtual space, and a deep neural network (DNN)-based diagnostic model will be sufficiently trained to uncover potential problems that were not considered by design.

The high-fidelity model associates the fault state with specific related components by simulating and displaying the internal interaction and evolution process mechanism of physical entity faults, thereby improving the comprehensiveness of fault-related data. Garza et al. [29] use high-fidelity digital models and simulation to increase the performance prediction and health management mechanism by four times.

3.2.2. Multi physical model fusion

Specific models can be built for each physical characteristic of the equipment, including various physical models, such as structural dynamics model, thermodynamic model, fatigue damage model, etc. Digital twins can build process models and data analysis models. These models can realize the dynamic construction mechanism based on data, and can also realize the separation management mechanism between models and data. The model can dynamically load the required real-time data and historical data. These mechanisms can not only solve the problem of insufficient model accuracy in qualitative model-based prediction methods, but also solve the problem of requiring a large amount of historical data in data-based algorithms. PdMDT can connect these models according to different physical characteristics, realize the combination of multiple twins through the interaction between twins, and construct complex digital twins, so as to give full play to its simulation, diagnosis, prediction and control functions, and effectively solve the problem that it is impossible to establish accurate analytical models for large-scale systems and complex systems in traditional methods. From the perspective of the digital twin physical model and the virtual model-based prediction method, He et al. [30] summarize the digital twin RUL prediction method for gear performance degradation. Qiao et al. [31] propose a data-driven digital twin model and a hybrid model prediction method based on deep learning. This method creates prediction technology for enhancing the state prediction of machining tools.

At the same time, the digital twins based on the multi-physical integration model can more accurately reflect the real state and behavior of physical devices in the physical space, so that they can detect the function and performance of physical devices in the virtual space, achieve intelligent perception and interconnection, and efficient data transmission and integration [32]. At the same time, they solve the problem that traditional methods analyze each physical characteristic model separately. At present, The United States Air Force Research Laboratory is carrying out an experiment, which has built a digital twin integrating different physical attributes to achieve accurate prediction of aircraft life [33]. From this point of view, multi-physical model fusion is an important technical means to improve the virtual and real fusion of the digital twin system and give full play to its role.

3.3. High confidence simulation prediction

High confidence simulation prediction is the core function of digital twins. After the completion of high-fidelity model, digital twin can correlate inspection and measurement data, key technical state parameters, etc., and carry out the analysis of physical equipment state prediction based on physical model and data-driven prediction and analysis model, such as equipment health state monitoring, remaining useful life and fault prediction.

3.3.1. Fault detection and prediction

Fault detection and fault prediction are the functional modules of the system and the evaluation of the system state. They are used to describe the health state of the system, including whether the system fails or the probability of future failures, the severity of failures, etc.

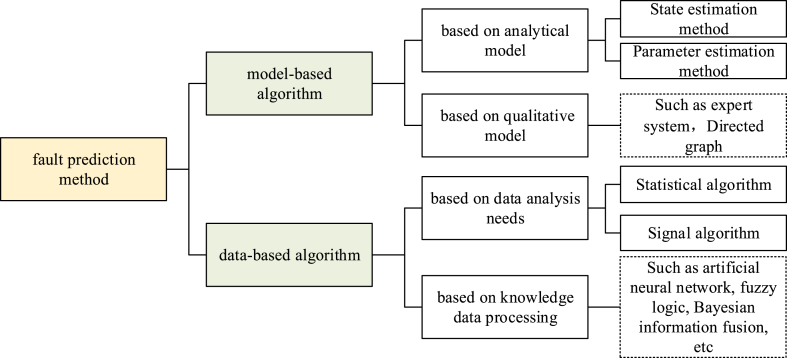

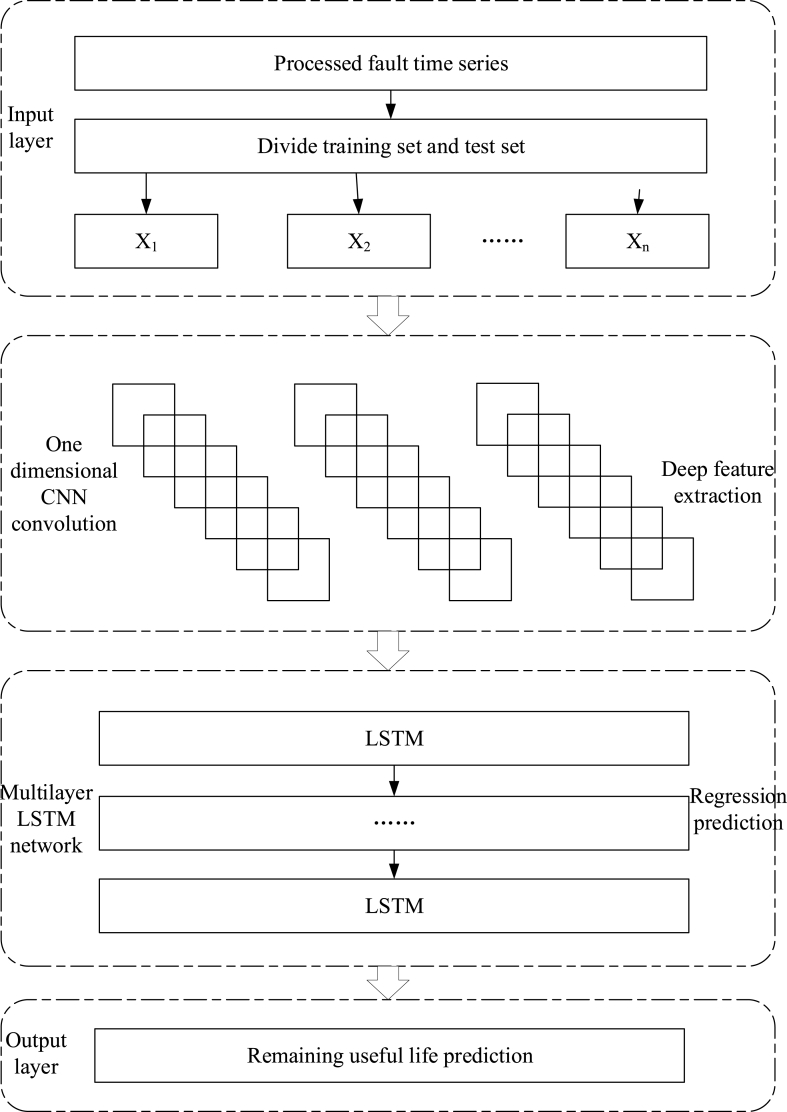

At present, the methods of equipment fault prediction mainly include two categories: one is model-based algorithm, the other is data-based algorithm [34]. Lin put forward it. The specific classification is shown in (Fig. 1, Fig. 3).

Fig. 1.

General reference model of digital twin.

Fig. 3.

Classification of fault prediction methods.

The fault prediction method based on analytical model needs to know the accurate physical model of the system, and consider the interference factors in the system operating environment, the wear of components and other related factors in the model. Such as dynamic nonlinear differential equations based on structural damage accumulation. The advantage of this method is that it can predict the remaining useful life of components without system state value, but the disadvantage is that it can not consider the influence of system operation and other modeling factors on components. Chan et al. [35] proposed a time-dependent physical crack propagation model and carried out experimental verification in the turbine propulsion system; Sun et al. [36] improved the physical model to the state space model, and verified the effectiveness of the method using the degradation data of gas turbines.

The fault prediction method based on qualitative model, when establishing the system model, it is necessary to consider the fault transmission relationship between nodes, which is used to predict the impact of the fault of a system element on other system elements. For example, the system symbol directed graph based on time delay uses independent signal analysis to obtain the delay time of fault transmission between nodes, which is used to predict the failure of other nodes in the future after a node fails. Based on this model, the corresponding relationship between node system state and fault state is established, which can be used for fault prediction. Villalon [37] proposed an adaptive prediction method, which weights the information of each model and significantly improves the prediction results. Yan [38] proposed an integrated prediction method that takes into account the nonlinear relationship between models, and verified it by the milling cutter life experiment.

The fault prediction method based on data analysis needs to use historical data to find the corresponding relationship between the statistical characteristics or time domain and frequency domain characteristics of system fault and system state value. After collecting the current system state value, it is analyzed and compared with historical data for fault prediction. Xia [39] proposed a multi-scale integration method of automatic encoder based on similarity, which improves the prediction accuracy by considering the difference of equipment degradation rate, monitoring data length and fault mode. Kordestani [40] extracts various features from vibration signals and uses fusion methods to predict the failure of wind turbine bearings.

The fault prediction method based on knowledge data processing uses artificial intelligence to perform statistical analysis on historical data to obtain the corresponding relationship between the system status value and the system fault, and the system fault information can be predicted by inputting the current system status value. The application of this method includes neural network, fuzzy logic and so on. Sun [41] proposed a fault prediction method based on improved multi-scale replacement entropy and dual-attention mechanism of long-term and short-term memory to realize fault prediction of AC contactor. Xu [42] proposed a new knowledge extraction framework, refining the complex process of the prediction method based on long-term and short-term memory network.

3.3.2. Remaining useful life prediction

Remaining useful life (RUL) prediction is based on system data and related technologies to accurately predict the possible failures and fault locations of the system in a period of time in the future, and accurately predict the remaining useful life of the system components. RUL prediction is helpful to take timely repair measures to faulty components to ensure the normal operation of the system and the smooth completion of tasks.

From the perspective of digital twin driven virtual modeling, RUL prediction includes non-deep learning and deep learning methods. Non-depth learning methods include Wiener process, hidden Markov model (HMM), regression model, etc. Deep learning methods include deep neural networks (DNN), convolutional neural networks (CNN), etc.At present, the industry mainly focuses on the research of dynamic Bayesian algorithms and deep learning algorithms.

Aivaliotis et al. [43] describe the methods and mechanisms developed and evaluated by RUL prediction in EU projects. RUL computing is integrated into a general framework called “maintenance application machine behavior prediction tool (BPT)". Anis et al. [44] extend the long and short term memory (LSTM) RNN technology to generate high-precision and low error RUL prediction within the digital twin framework. Xu et al. [28]through a two-stage digital twin fault diagnosis method based on deep transfer learning (DFDD), the previously trained diagnosis model is migrated from virtual space to physical space, so as to realize real-time monitoring and predictive maintenance.

3.3.3. Maintenance demand and maintenance cost prediction

Combined with digital twin, it can also carry out demand analysis and cost prediction for the maintenance process. Digital twin can perform all processes in the planned task, predict the maintenance demand and maintenance cost of the equipment during this period, and plan subsequent tasks and costs. Lu et al. [25] use computer simulation technology to reduce its production and test costs, so that the digital twin model has the ability of fault diagnosis and optimal design. Heim et al. [45] can estimate the support requirements of the formation during this period by modeling the digital twins of each aircraft in the formation. Maintenance activities and component replacement can be reflected through digital twin data update to realize configuration control of a single aircraft.

3.4. Difference

Through the above description of the characteristics of PdMDT, the differences between PdMDT and traditional predictive maintenance are sorted out. The differences between PdMDT and traditional predictive maintenance are summarized in Table 1.

Table 1.

The differences between PdMDT and traditional predictive maintenance.

| Equipment Simulation | Maintain Data | Maintenance Timing | Data Utilization | |

|---|---|---|---|---|

| Traditional PdM | Static simulation | Insufficient data | Expert experience judgment | Low effective utilization, prediction results are one-sided |

| PdMDT | Dynamic simulation by digital twin technology, can simulate physical characteristics and evolution mechanism | All factors, multi type data can be collected and use | Real time data analysis and can give maintenance timing by software | Ability to use all data, Efficient depth analysis and mining by artificial intelligence |

| Maintenance Efficiency | Fault Data Reserve | Model Fidelity | Fault Prediction Accuracy | |

| Traditional PdM | Vulnerable to equipment changes | Insufficient enterprise fault data | Poor | Poor |

| PdMDT | Real time changes according to equipment changes | Sharing fault data between enterprises | Reflecting physical characteristics, dynamic interaction and evolution mechanism, multi physical model fusion | High |

4. Application area

PdMDT can be applied to various areas. This section will introduce and discuss some representative areas, as shown in Table 2.

Table 2.

Main application area and literature research of PdMDT.

| Application area | References | |

|---|---|---|

| Intelligent manufacturing | Process equipment | [27,28,31,43,[46], [47], [48], [49], [50], [51]] |

| Automobile manufacturing | [25,52,53] | |

| Cyber-physical systems | [20,[54], [55], [56], [57]] | |

| Product lifecycle management | [58,59] | |

| Fault diagnosis | [[60], [61], [62]] | |

| Power industry | [[63], [64], [65], [66], [67], [68]] | |

| Construction | [18,[69], [70], [71], [72]] | |

| Aerospace industry | [[73], [74], [75], [76], [77]] | |

| Shipbuilding industry | [[78], [79], [80], [81], [82], [83], [84]] | |

4.1. Intelligent manufacturing

For decades, manufacturing technology has developed rapidly in the flood of information and communication technology (ICT). Many technologies in the past are the extension of ICT, such as computer numerical control (CNC), computer aided design (CAD), etc.

In the manufacturing field, digital twins can comprehensively improve the production process efficiency and production line operation efficiency by simulating and predicting all aspects of equipment manufacturing and process cycle. In the manufacturing scenario, the production line can be divided into two parts: spatial dimension and temporal dimension from different dimensions. To build corresponding virtual expression models in the information world for different levels, simulate the operation state of equipment, monitor the operation state of manufacturing equipment and process in the interaction with the target system, and make analysis, prediction and decision [[85], [86], [87]]. Intelligent manufacturing is gradually emerging in current technological development. It is a manufacturing paradigm for optimizing resource allocation. It has the characteristics of real-time analysis, intelligence, refinement and agile perception of the real-time state of the market and customers. It has changed from mass production to customized production.

4.1.1. Process equipment

With the rapid digitization of manufacturing, the amount of data generated by industrial facilities is greater than ever before. In order to make full use of a large number of available processes and equipment data in modern industrial complexes, the design of health management strategy is very important.

Computer numerical control machine tools (CNCMT), as the mother machine of the industry, is an important manufacturing equipment. Nowadays, many industrial projects need to rely on highly precise machine tools composed of hundreds of components. The components in the machine tools need to be monitored and maintained to avoid failures affecting work efficiency. In order to ensure the continuous work of the production line, it is necessary to understand the health of each machine tool and its components. If the failure is not eliminated in time, the failure of CNCMT may cause loss of accuracy and affect production. Luo et al. [46] studied a hybrid method driven by digital twins. This method is a hybrid predictive maintenance method based on digital twin models and data-driven in digital twin. An example of tool life prediction is studied. Aivaliotis et al. [27,43] use digital twins to calculate the remaining useful life of mechanical equipment under the physics based simulation model to monitor and predict the condition and state of the machine through model simulation. If the health status of each piece of equipment can be known at any time, the maintenance plan will be easier to arrange. Booyse et al. [47] do not rely on historical fault data to estimate asset health, detect early faults in the form of deep digital twins (DDT)to track asset degradation and distinguish fault modes under stationary and non-stationary operating conditions. In addition, due to the complex design of modern machines, creating digital models can be a demanding task. Aivaliotis [48] proposes a method based on advanced physical modeling. According to the method given in the article, users can define, create and utilize the digital model of resources.

Today, the increasing complexity of industrial equipment increases the demand for the use of new advanced technologies. Therefore, the future of manufacturing can be improved by developing new methods, tools and technologies to combine the importance of these new technologies. Under the digital framework, Mi et al. [49] establish a comprehensive mathematical programming model considering parameter uncertainty, which is solved by NSGA-II hybrid algorithm. Taking the predictive maintenance decision of large vertical mill roller bearing as an example, it is studied and verified. Qiao et al. [31] proposes a digital twin model for model prediction. This method creates a kind of prediction technology for enhancing machining tool state prediction. The experimental results show that the proposed digital twin model for tool wear prediction is effective. Xu et al. [28] proposed a digital twin framework for fault diagnosis. Through the application of deep transfer learning technology (DFDD) in the digital twin framework, fault diagnosis in the equipment development and maintenance stage can be realized. If the health of each equipment can be known at any time, the maintenance plan will be easier to arrange. Rabah et al. [50] uses digital twins to propose the AR solution, which becomes part of the predictive maintenance framework. Raileanu [51] proposes a digital twin system to optimize the workshop scheduling of the embedded workshop transportation system in the global manufacturing scheduling and control system, and realizes the early detection of conveyor anomalies.

4.1.2. Automobile manufacturing

In recent years, the development of the automobile manufacturing industry has become more and more mature, and the development of the automobile has become more intelligent, integrated and personalized, and the quality control of the engineering on the automobile has become higher and higher.

The constant speed universal joint is the core part of the automobile transmission system, it needs to ensure its reliability and stability, which is very important for the safe operation of the automobile. Lu et al. [25] establish a multidimensional digital twin model of the product life cycle of constant velocity universal joint. The algorithm analysis and empirical evaluation are used to process the real-time data to achieve the purpose of predictive maintenance of constant velocity universal joint. Moghadam et al. [52] propose a multi degree of freedom transmission torsional model as a digital twin model to monitor the remaining useful life of transmission components, and verify the application of the model in the prediction of the remaining useful life of gearbox. Rajesh et al. [53] introduce a digital twin model supporting predictive maintenance of automotive braking system, which uses the data obtained by ThingWorx Internet of things platform to predict brake wear.

4.1.3. Cyber-physical systems

In recent years, cyber-physical systems (CPS) and the Internet of Things (IoT), which have combined tangible and virtual entities, have penetrated into the daily life of modern society, and have become more and more symbiotic with humans. Their appearance under the theme of Industry 4.0 presents new challenges and opportunities for the integration of global manufacturing technology and ICT [88].

Among them, digital twins are becoming a very promising example of runtime modeling and performance prediction of CPS. With the rapid development of computer science and mathematical modeling, fast algorithms and industrial Internet of things (IIoT) platform, as well as immersive user experience, it is becoming easier and easier to have a digital twin in the whole product life cycle. In the past few years, the word “digital twin” itself has been mentioned and defined in many publications. Lin et al. [20] studied the conceptual design and implementation of a network physical digital twin system for manufacturing. Based on the literature review and industry requirements of network physical digital twin system in manufacturing industry, a conceptual design architecture and implementation method of network physical digital twin system are proposed. Flammini [54] introduces a conceptual framework based on autonomous system to host the digital twin runtime model in a structured and systematic way, so that the network physical system can self-monitor, self-diagnose and finally self-repair. Barthelmey et al. [55] consider the impact of flexibility on predictive maintenance strategies. Through the digital twin and its update service and label interface, the basic components of the predictive maintenance system of the flexible production system are introduced.

Digital twins can also act on distributed networks. Zhang et al. [56] provide an example, using the distributed network based on digital twins to distribute computer programming, software and data on multiple terminals, passing complex messages through the terminal nodes, and relying on each other, thereby avoiding the pressure of the master station. Digital twins are used to track the performance of equipment (such as transformers) during normal operation to detect possible defects and repair them before causing faults. Altun and Tavli [57] propose a reference model for predictive maintenance of commercial equipment, in which digital twins interact socially through distributed ledger technology.

4.1.4. Product lifecycle management

Online condition monitoring service and product life cycle management have increasingly become the key to prolonging the system life and detecting faults early. In recent years, enterprises pay more and more attention to product quality management. The product life cycle management and product online condition monitoring service realized under the digital twin just meet this point. Khalil et al. [58] introduce an application that obtains machine data and processes it on the IIoT platform to obtain system health and visualize the results online in the augmented reality user interface. Khan [59] believes that independent maintenance is the focus of current technology research and development, and discusses the role of digital twins as a decision-making tool.

4.1.5. Fault diagnosis

Fault diagnosis based on digital twin technology provides a new paradigm for intelligent manufacturing. The traditional data-based fault diagnosis method usually assumes that the training data and test data obey the same distribution, which is unrealistic in the actual production process, and the actual production process is dynamic. Dynamic model in this case, models with analysis specific levels of detail must coexist, interact and maintain mutual consistency. Cimino et al. [60] propose a modeling method to solve the inconsistency of dynamic models in the case of virtual and real interaction, and give a support example based on object-oriented modeling language. At the same time, these dynamics of a system's environment can render the underlying model unfit the changing reality and thus cripple the whole approach. By combining the probability of discovery calculation with the established process control method, Borth and Gerwen [61] provide a method to detect digital twins and similar technology operation space violations, and localize the necessary updates to ensure effective model maintenance. Vathoopan et al. [62] introduce a new modular corrective maintenance method, which uses the digital twin of automation module. Through its digital twin and related visual interface, it provides fault attribution support for manual technicians performing corrective maintenance operations of automation modules.

4.2. Power industry

At present, digital twins are relatively mature in aerospace, workshop, oil, gas and other industries. However, the research and application of the power industry is still in its infancy. In the power industry, the application of digital twin technology mainly includes predictive maintenance of power generation equipment, monitoring and management of power content, and real-time control of power grid.

The combination of digital twin and predictive maintenance has great development potential and broad innovation space. Righetto et al. [63] propose the concept of predictive maintenance 4.0. The construction module of the system architecture, its application in the electrical industry and its advantages as innovative technology are predicted. Rassudov et al. [64] focus on the application of digital twin technology, predictive maintenance and fault diagnosis technology in the education of electrical engineers.

By improving the understanding of system design and operating conditions, digital twin technology can provide important value for prediction and health management (PHM) of key power plant components. The digital pairing of the system can be used for anomaly detection, diagnosis and estimation of the remaining useful life of the system, so as to optimize the operation and maintenance process of the nuclear power plant. Oluwasegun and Jung [65] apply the conceptual framework of digital twin technology predictive control element driving mechanism (CEDM) and the data-driven method of anomaly detection using coil current profile to realize the health monitoring and predictive maintenance of power plant components. Venkatesan et al. [66] develop the health monitoring and prediction of permanent magnet synchronous motors by creating intelligent digital twins in Matlab/Simulink.

Aiming at the problems of changeable operation environment and difficult operation data acquisition of electromechanical equipment, Lu et al. [67] propose a digital driven electromechanical equipment operation simulation system and application framework. The effectiveness of the system is verified by the simulation of the electronic accelerator pedal. Huang et al. [68] analyze the application of digital twins in power system control, equipment fault prediction and diagnosis, power on-line analysis and so on. A new generation of intelligent power system (SPS) is developed. The system uses the data flow generated by the smart grid to drive digital twins and comprehensively improve the intelligence of power grid operation.

4.3. Construction

In recent years, the use of digital twins in the construction industry is relatively limited. With the continuous introduction of the Internet of Things technology in the construction industry, facility maintenance is developing towards predictive maintenance based on digital twins technology. Intelligent buildings are becoming the next frontier in the development cycle of building structure. Programmable services are being embedded in residential buildings, including heating system, cooling system and home appliance integration. This cooperation is between the largest home appliance manufacturers and Internet companies, such as Amazon, Google and Microsoft.

4.3.1. Intelligent building maintenance

Intelligent buildings use BIM (building information modeling) for facility management, but they lack the prediction ability of digital twins. Predictive maintenance of building facilities requires continuous updating the data of building components through integrated sensors. The main challenges in developing predictive maintenance tools for building facilities are the integration of the Internet of things, the visualization of Internet of things data on three-dimensional building models, and the implementation of maintenance management systems on the Internet of things and building information modeling (BIM). The current 3D building model cannot fully interact with the building facility data of the Internet of things. Coupry et al. [69] introduce the project of using the combination of digital twin technology and extended display technology to improve the maintenance operation of intelligent buildings, summarized how BIM was used to create digital twin, and how this digital twin combined with XR (extended reality) technology could improve the maintenance operation in intelligent buildings. Villa et al. [18] propose digital framework integration based on Internet of things and BIM platform to realize building intelligent monitoring and maintenance. Khajavi et al. [70] use more than 25000 sensor reading examples to create and test the finite digital twin model of office building facade elements, and study the expansion of digital twin in building life cycle management. Jakobi et al. [71] show how the pairing of construction projects and digital twin can establish predictive maintenance services and minimize the downtime of the heating system. Jafari et al. [72] combine the existing asset management theory with building simulation technology, and propose a new architecture to realize an effective maintenance strategy and operation control scheme.

4.4. Aerospace industry

The operation safety of aeroengine is affected by the environment, time, conditions and the degradation or failure of various components. Unpredictable component failures may occur during the operation. If the fault cannot be solved in time, catastrophic accidents may occur [89]. The modern aerospace industry is changing from reactive maintenance to active and predictive maintenance. Accurate predictive maintenance can improve the operational availability and efficiency of the platform, realize the coordination of ensuring transportation safety and reducing operation cost, improve the reliability and safety of equipment operation, shorten maintenance time, prolong aircraft life and reduce its life cycle cost. To meet these challenges, powerful new technologies are needed to help make faster and smarter decisions to achieve optimal maintenance and avoid any catastrophic failures.

Predictive maintenance can determine when to carry out maintenance according to the actual situation of aircraft structure, components and subsystems. Once in place, predictable additional costs, such as the rapid transportation cost of parts or supplies, can reduce the overtime cost of crew and, most importantly, unscheduled maintenance downtime [74].

Current predictive maintenance methods mainly include reliability statistics and methods based on physical model and data-driven [90]. These traditional research methods are usually passive and heuristic [89], which can not diagnose faults or evaluate potential risk operations in time, let alone adjust to the safe operation of civil aircraft in time. Industry 4.0 provides strategies for predictive maintenance of equipment [91], and brings opportunities and challenges for digital manufacturing and assembly [92]. With the development of artificial intelligence technology, digital twins, as a technical means to realize these advanced concepts, provides an effective solution for accurate intelligent prediction and maintenance of equipment.

Xiong et al. [73] studied the predictive maintenance framework of aeroengine driven by digital twin, and mined the implicit digital twin model. Through the consistency evaluation of virtual data assets and real data assets, the effectiveness of the model is verified. Heim et al. [45]provide several methods to describe the remaining useful life of a given part for aircraft maintenance through two separate aircraft data sets. Then it shows how to combine these results with the digital twin model to help design a sufficiently stable supply chain and maintenance strategy. Liu et al. [74]review the overall framework of developing digital twins in combination with industrial Internet of things technology to promote the autonomy of aerospace platforms. The role of data fusion in the digital twin of aircraft predictive maintenance is determined. Monitoring aircraft performance in the fleet is essential to ensure optimal operation and timely detect abnormal conditions that may increase fuel consumption or endanger flight safety. The main challenges of fleet monitoring are the large amount of collected data to be processed and the variability between fleet engines, which requires adaptive models. Zaccaria et al. [75] propose a fleet monitoring, diagnosis and health management framework. The framework includes a multi-level method: starting from threshold exceeding monitoring, isolating the problematic engine, and then applying the fault detection system. Ezhilarasu et al. [76] propose a simplified aircraft health management method based on digital twin, which is demonstrated in three test cases: engine, environmental control system and fuel system. In each case, the digital twin device, the simulation conditions of health and fault scenarios, and the methods based on OSA-CBM (open system architecture based on condition based maintenance) to diagnosis are introduced in detail. Mazzuto et al. [77] propose a framework for developing the digital twin device of the injector, which can predict the future status of the project and the impact of negative scenarios and fault diagnosis.

4.5. Shipbuilding industry

Digital twin technology is widely used in the shipbuilding industry, among which offshore wind power industry and shipping industry have great prospects. Both of them have data sensitive systems with high downtime and maintenance costs, so appropriate maintenance strategies are needed.

4.5.1. Shipping industry

The shipping industry accounts for about 90% of World Trade and has a significant impact on the environment. Therefore, a key issue in the shipping industry is to develop technologies that can improve ship efficiency by reducing fuel consumption and unnecessary maintenance operations. For example, the marine fouling phenomenon has a profound impact, because in order to prevent or reduce the growth of fouling affecting ship consumption, expensive dry docks are required to clean the hull and propeller, and must be arranged according to the speed loss estimation. Coraddu et al. [78] use a large amount of information collected from the sensors on the ship to build a data-driven digital twin model of the ship, which is used to estimate the speed loss caused by ocean pollution. The results clearly show the effectiveness of the scheme, and the speed loss prediction accuracy relative to the actual standard, thereby reducing fuel consumption due to fouling.

For ship performance prediction, condition evaluation, and finally the important implementation of digital twin technology in the marine industry, it is still necessary to basically explore the algorithms and methods, so as to link, compare and fuse the numerical model used in the digital twin model with the real-world sensor data. Johansen et al. [79] use the digital twin method to monitor the condition of the transmission system in the marine power transmission system. Schirmann et al. [80] develop a preliminary digital twin for surface ships. Given the weather forecast or post measurement data of the selected route, the cumulative fatigue damage of four simulated routes in the Pacific Ocean is predicted and compared, and the simulated predicted motion with the largest fatigue damage is analyzed to investigate the possible causes of damage increase.

4.5.2. Offshore wind industry

In recent years, with the rapid development of global wind energy, offshore wind turbine (OWT) has been more widely used. Because the support structure of OWT is easy to be damaged, more and more offshore wind farms require highly reliable wind turbines to reduce maintenance costs and reduce downtime. Therefore, it is very important to strengthen structural reliability to prevent accidental failures and reduce operating costs by performing fault diagnosis, remaining useful life prediction and condition based maintenance.

Wang et al. [81] introduced the latest progress in structural reliability analysis of OWT support. According to the digital twin technology, by introducing digital twin into the OWT support structure, real-time monitoring, fault diagnosis and operation optimization of the OWT support structure will be realized. Through the real-time monitoring of the operation state of the OWT support structure, the operation measurement values can be obtained to detect the initial structural cracks and predict the crack propagation, so as to evaluate the potential risks and carry out timely maintenance.

The information Augustyn et al. [82] obtained from the digital twin is used to quantify and update the uncertainties associated with structural dynamics and load modeling parameters in the accumulation of fatigue damage. The updated uncertainty is included in the cumulative probability model of fatigue damage, which is used to update the structural reliability. The updated reliability can be used as the input of the optimization decision model, used for the operation and maintenance of the existing structure and the design of the new structure. Moghadam et al. [83] propose a digital twin condition monitoring method. These include torsional dynamic model, on-line measurement and fatigue damage estimation for remaining useful life (RUL) estimation.

Power converter is one of the key components with high medium and short-term thermal cycle rate, especially in offshore floating wind turbine, compared with fixed bottom turbine. Sivalingam et al. [84] propose a digital twin method to predict the remaining useful life of power converter as a means of predicting maintenance strategy. The remaining useful life of diagnosis and prediction of offshore working environment and health monitoring is estimated.

5. Conceptual framework for PdMDT

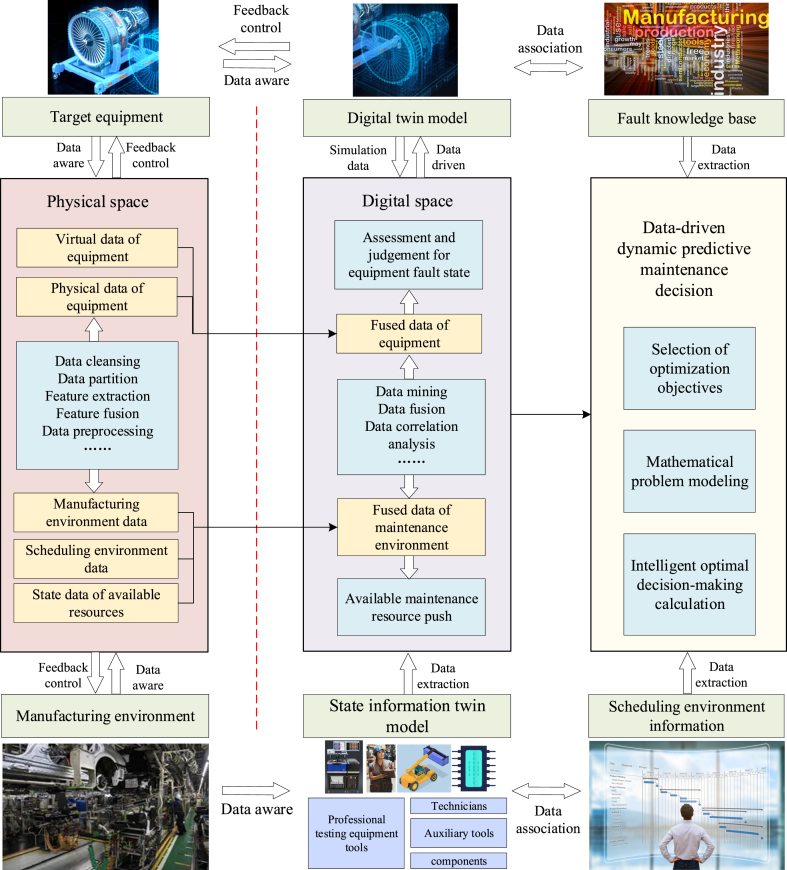

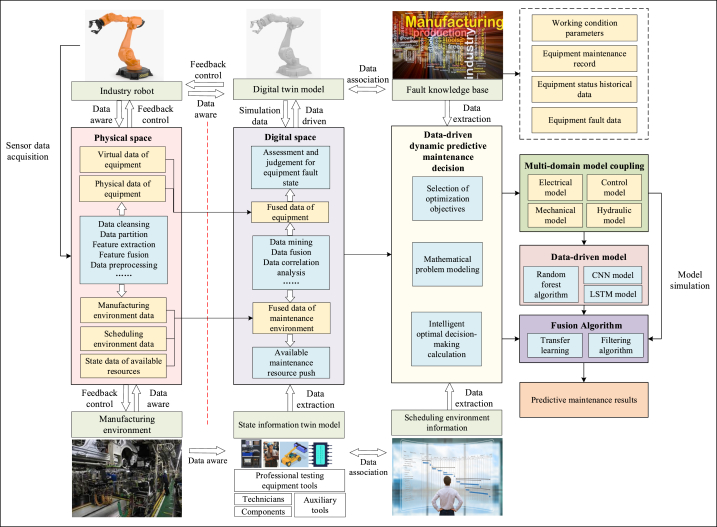

Through the discussion on the application field of digital twins, we have made corresponding thinking on the predictive maintenance application of digital twins in the manufacturing industry. The reference samples cited in this paper basically cover various application fields of digital twins. According to the proportion of references, 50% of the academic papers produced by digital twins in the field of manufacturing applications. Therefore, based on the characteristics and applications of PdMDT, we propose a digital twin reference framework for manufacturing to illustrate the key functional modules and implementation processes of PdMDT in manufacturing, and describes the key technologies involved in PdMDT, namely, data acquisition layer, data fusion layer and service decision-making layer, as shown in Fig. 4.

Fig. 4.

Digital twin collaborative perception and interconnection framework for all factors of maintenance decision environment.

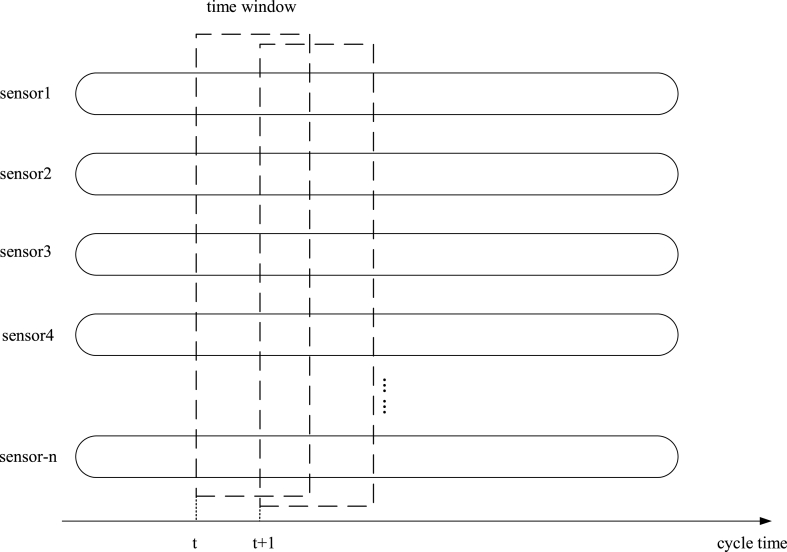

5.1. Data acquisition layer

The data acquisition layer is the basis of realizing the all factors perception ability of maintenance decision-making environment. The data acquisition layer includes the target equipment and relevant maintenance resources. The target equipment refers to the main object of fault diagnosis and prediction, and the relevant maintenance resources refer to all relevant resources in the manufacturing environment of the target equipment. The collection and interaction of raw data are realized in physical space. With the help of embedded network devices (such as sensors, controllers and energy monitors) and interconnected communication technologies (such as industrial fieldbus, Internet of things, wireless sensor network, mobile Internet and global positioning system), the data acquisition layer establishes a data acquisition network with full factor perception of maintenance decision environment to perceive and collect the operation status parameters and operation environment information of the target equipment, To construct the virtual mapping between physical devices and digital twins of devices. Limited by the actual engineering conditions, some data are obtained indirectly. For example, it is difficult to collect a target parameter directly, and it is difficult to place a sensor. The target parameter can be extracted through relevant brief data and analysis methods [93].

With the help of data processing technology, the collected data are preprocessed, including data noise removal, data segmentation, feature extraction and feature fusion. After filtering, equipment virtual data, equipment physical data, manufacturing environment data, scheduling environment data and available resource status data are obtained. The filtered data is uploaded to the data fusion layer and the digital twin model of the target equipment. In the digital twin model, these data are used to drive its revision and update, and are saved as historical state data.

The types of relevant data to be collected in the manufacturing industry are described in Table 3.

Table 3.

The types of relevant data to be collected.

| Type | Data source | Description |

|---|---|---|

| Equipment operating data | Equipment user enterprise | Used to extract equipment status parameters, including equipment failure data, equipment failure indicators, process quality indicators, remaining service life indicators, etc. |

| Manufacturing environment data | Equipment user enterprise | Used to extract relevant information and data in the manufacturing environment. |

| Resource state data | Resource provider | Used to extract available resource data in the current physical space, including space location, scheduling cost, personnel cost, resource status, etc. |

| Scheduling environment data | Third party service provider | It is used to extract the scheduling environment data in the current physical space, including environment location, scheduling time, environment cost, etc |

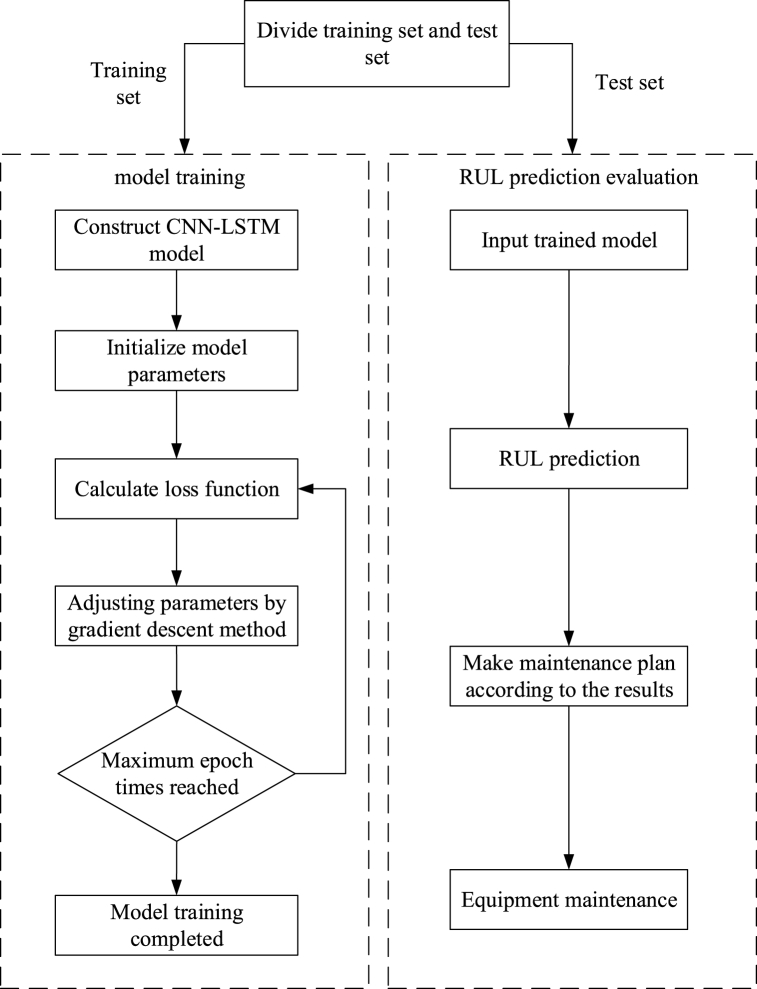

5.2. State judgement layer

The state judgment layer reprocesses the data processed by the data acquisition layer and judges the equipment state. The data collection layer constructs multi-dimensional heterogeneous data sources, which cannot be used directly. Before the application of the service decision-making layer, a series of processing such as data cleaning, integration and conversion are needed to unify the format of heterogeneous data in the data source and eliminate garbage data. This process is collectively referred to as data fusion. In some cases, some high-capacity computing tasks need to be carried out, including data correlation analysis and data mining, which depends on what characteristic parameters are required for equipment state analysis. Through the above operations, the equipment fusion data and maintenance environment fusion data are obtained, and the synchronization of virtual data and real data is ensured through data communication, so as to achieve the equipment operation simulation and maintenance process simulation based on digital twin. Compare the processed real-time data with the fault knowledge base (the fault knowledge base includes the historical data of equipment status, equipment fault data, equipment maintenance records, etc.) to evaluate and diagnose the equipment fault status. If there is a fault or fault symptom, push the available maintenance resources according to the fusion data situation of the maintenance environment. Available maintenance resources include technicians, professional test equipment, equipment auxiliary tools, relevant components, scheduling information, etc.

5.3. Service decision-making layer

The service decision-making layer mainly realizes the dynamic predictive maintenance decision driven by data, including the selection of optimization objectives, mathematical problem modeling and Intelligent optimal decision-making calculation.

The selection of optimization objectives specifically refers to the selection of components in the equipment that need fault prediction/maintenance decision according to the real-time data situation of each component. In general, select the key components that can represent the health state of the equipment. For example, for industrial robots, its main action is the rotation at the joint. At this time, the motor module at the joint can be selected for predictive maintenance.

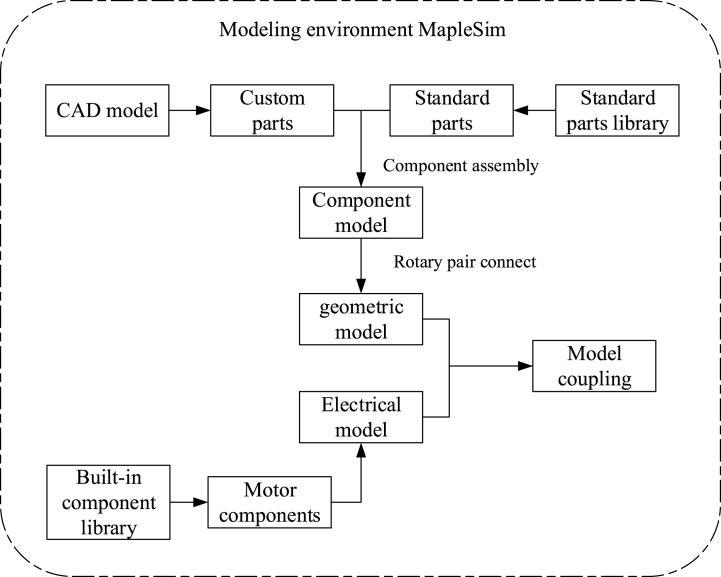

Mathematical problem modeling is to build its mechanism model according to the operation principle of the selected components. The mechanism model can be the mathematical model of components in many fields, including control model, mechanical model, hydraulic model, etc.; it can also be a mathematical model for fault prediction/decision optimization. These mathematical models are used to reflect the prediction methods and decision-making conditions of components, so as to assist the intelligent optimization decision-making calculation of equipment. In addition, by modeling the mathematical problems of the equipment, it can realize multi domain model coupling.

Intelligent optimal decision-making calculation is to select the corresponding algorithm to train the processed data according to the component failure situation and mechanism model, predict the fault/remaining useful life after the data training, obtain the prediction results, and make maintenance decisions.

To sum up, the framework proposed in this paper is based on the high fidelity digital twin model, which combines knowledge data with expert assistance to determine and correct the maintenance resource requirements. With the help of the digital twin model under the all-factor perception environment, it can carry out visual maintenance scheduling for industrial equipment, and can analyze all types of fault analysis data through the dynamic control of the physical model by the digital twin model. Combined with the data analysis technology in the digital twin, the data-driven prediction and equipment operation and maintenance simulation based on the digital twin are realized, which improves the accuracy and timeliness of fault diagnosis and life prediction. Therefore, the realization is based on the predictive maintenance of equipment based on the digital twin.

6. Example of industrial robot

On the basis of the framework proposed in Section 5, this section will introduce the PdMDT example of an industrial robot under this framework (Fig. 5).

Fig. 5.

Industiral robot under PdMDT framework.

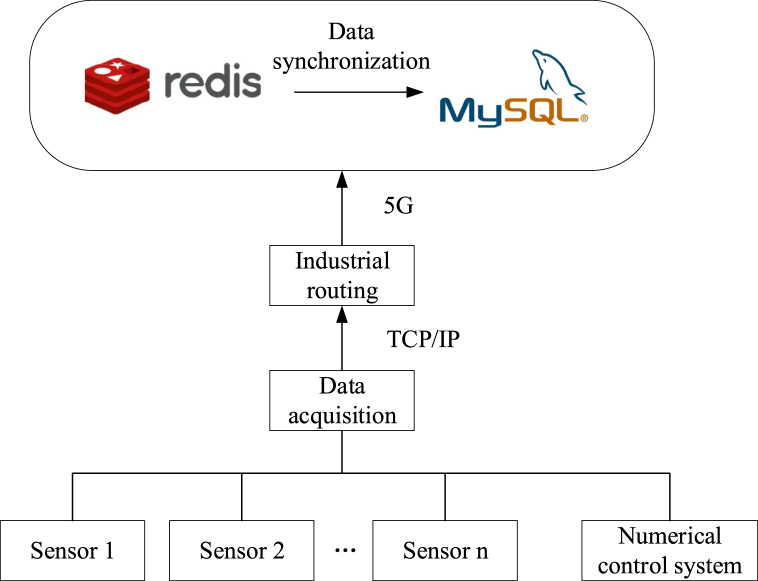

According to the analysis of the digital twin collaborative perception and interconnection framework and key technologies of all factors of the maintenance decision environment, this paper first establishes the digital twin framework system of industrial robot. It is mainly divided into data acquisition layer, data fusion layer and service decision-making layer, as shown in the figure. This paper will introduce the specific work according to the framework (Fig. 6).

Fig. 6.

Schematic diagram of data collection.

6.1. Data acquisition

The data acquisition layer is responsible for collecting the original data. The industrial robot mainly collects the original data through the sensors on the equipment and the numerical control system, and communicates through TCP/IP protocol to realize the collection and transmission of complex, coupled and time-varying data in physical space. The obtained data is uploaded to the data storage platform through industrial route. Considering the real-time nature of data access and the persistence of data storage, the real-time nature of data access is achieved through the deployed 5G network and Redis database. 5G network greatly reduces the data transmission delay, and Redis speeds up the data storage. The persistence of data storage is realized through MySQL database, and all data will be synchronized to MySQL database through Redis.

The multi type sensing data collected from the industrial robot and the relevant environmental data obtained from the manufacturing environment need data preprocessing, including data noise reduction, data segmentation, feature extraction and feature selection, etc., and then the effective feature parameters obtained from the analysis are used as the health state index of the performance of the industrial robot, It is stored in the equipment fault knowledge base (the fault knowledge base includes equipment status history data, equipment fault data, equipment maintenance records, etc.) to provide effective information for the update of service decision-making layer and digital twin multi domain model, and data-driven algorithm training and prediction.

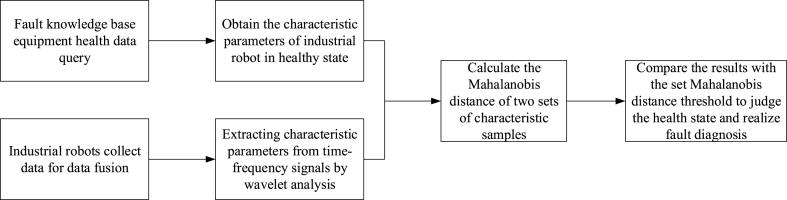

6.2. State judgement