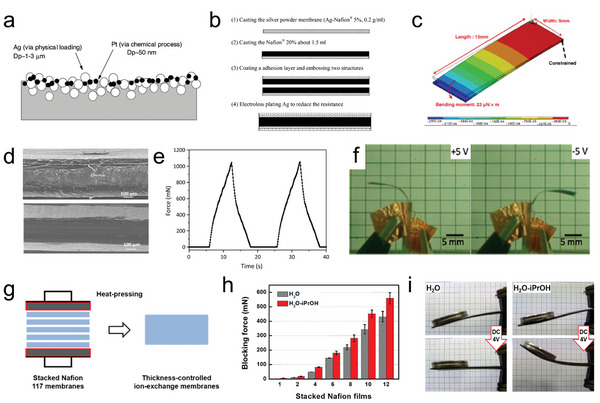

Figure 8.

a) Schematic process illustration of the actuator with a physically loaded particulate electrode. b) The processing flow of the IPMC actuator with Ag nano‐powders. c) Simulation of the actuating behavior of the IPMC actuator with the Ag (nano‐powders)–Nafion 5% electrode. d) Cross‐sectional SEM image of the SWCNT BP/EMI+SCN−‐Nafion/SWCNT BP actuator prepared at 80 °C/60 psi (top) and 120 °C/120 psi (bottom). e) Blocking force of the composite actuator at applied voltage of ±3 V with a frequency of 50 mHz. f) Bending motion of the actuator at ±5 V with a frequency of 0.15 Hz. g) Schematic diagram for preparing ultrathick IPMC actuators based on thickness‐controlled ion‐exchange membranes. h) Blocking force of the IPMCs for different thicknesses. The IPMCs were plated in water and in the H2O‐iPrOH solution. The blocking force was recorded with a load cell at a point 30 mm away from the grip under a potential of 4 V of DC for 30 s. i) Actuation test of the H2O‐ and H2O‐iPrOH IPMCs with dimensions of 20 × 60 × 1.0 mm3 under a potential of 4 V DC for 20 s. The weight of the coins was ≈15.4 g. a) Reproduced with permission.[ 112 ] Copyright 2002, Elsevier. b,c) Reproduced with permission.[ 113 ] Copyright 2006, Elsevier. d–f) Reproduced with permission.[ 57 ] Copyright 2017, American Chemical Society. g–i) Reproduced with permission.[ 44 ] Copyright 2017, American Chemical Society.