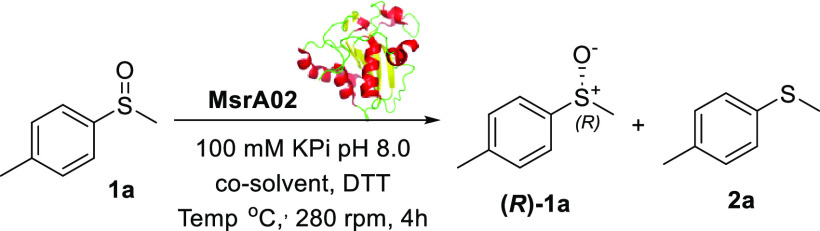

Table 2. Optimization of the KR of 1a with MsrA02.

| entry | MsrA02 (gL–1)a | 1a (mM) | DTT (equiv) | cosolvent | temp °C | (R)-1a yieldb % | eec % |

|---|---|---|---|---|---|---|---|

| 1 | 1.6 | 8.0 | 4.0 | IPA | 30 | 51 (51)d | 98 |

| 2 | 1.0 | 8.0 | 4.0 | IPA | 30 | 54 (51)d | 99 |

| 3 | 0.4 | 8.0 | 4.0 | IPA | 30 | 53 (52)d | 98 |

| 4 | 0.1 | 8.0 | 4.0 | IPA | 30 | 71 (86)d | 40 |

| 5 | 8.0 | 4.0 | IPA | 30 | >99 | <1 | |

| 6 | 1.6 | 16 | 4.0 | IPA | 30 | 54 | 99 |

| 7 | 1.6 | 32 | 4.0 | IPA | 30 | 52 | 99 |

| 8 | 1.6 | 64 | 4.0 | IPA | 30 | (48)d | 99 |

| 9 | 1.6 | 128 | 4.0 | IPA | 30 | 54 | 5 |

| 10e | 1.6 | 8.0 | 4.0 | IPA | 37 | 47 | 99 |

| 11 | 1.6 | 8.0 | 4.0 | MeOH | 30 | 46 | >99 |

| 12 | 1.6 | 8.0 | 4.0 | EtOH | 30 | 50 | >99 |

| 13 | 1.6 | 8.0 | 4.0 | IPA | 30 | 54 | >99 |

| 14 | 1.6 | 8.0 | 4.0 | CH3CN | 30 | 49 | >99 |

| 15 | 1.6 | 8.0 | 4.0 | DMSO | 30 | 90 | 5 |

| 16 | 1.6 | 8.0 | 4.0 | Neat | 30 | >99 | 5 |

| 17 | 1.6 | 8.0 | 1.0 | IPA | 30 | 45 | 99 |

| 18 | 1.6 | 8.0 | 0.5 | IPA | 30 | 69 (62)d | 64 |

| 19 | 1.6 | 8.0 | IPA | 30 | >99 | <1 | |

| 20 | 1.0 | 32 | 1.1 | IPA | 30 | 53 (48)f | 99 |

| 21 | 1.0 | 64 | 1.1 | IPA | 30 | 46 | 99 |

| 22 | 2.3g | 32 | 1.1 | IPA | 30 | (52)d | >99 |

| 23 | 10h | 32 | 1.1 | IPA | 30 | (52)d | >99 |

| 24i | 1.6 | 8.0 | 4.0 | IPA | 30 | 52 | >99 |

MsrA02 used as CFE.

1H-NMR yields are reported.

Determined by chiral HPLC using the Chiralpak IG column.

HPLC yield is reported.

1 h reaction time.

Isolated yield.

Pure MsrA02 enzyme was used.

Whole cell MsrA02 was used.

Reaction time was 18 h.