Table 4.

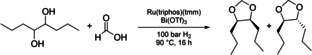

Utilization of 4,5‐octanediol from the enzymatic cascades as substrate for the synthesis of 4,5‐dipropyl‐1,3‐dioxolane.

|

| ||||

|---|---|---|---|---|

|

Entry[a] |

Substrate [x mmol] |

Formic acid [mL] |

Product ratio SS/meso |

Yield acetals[d] [%] |

|

1 |

4,5‐octanediol >99 % meso (1.4) |

0.3 |

0 : 100 |

11 |

|

2 |

4,5‐octanediol 93 % meso (1.4) |

0.3 |

34 : 66 |

13 |

|

3 |

4,5‐octanediol >99 % S,S (1.4) |

0.3 |

100:0 |

18 |

|

4[b] |

4,5‐octanediol >99 % S,S (1.4) |

2×0.3 |

100:0 |

31 |

|

5[c] |

4,5‐octanediol (1.3) without purification 89 % meso |

0.3 |

40 : 60 |

10 |

[a] Ru(triphos)(tmm) (0.003 mmol), Bi(OTf)3 (0.032 mmol), formic acid (0.3 mL), CPME (2 mL) 90 °C, 16 h, H2 (100 bar). [b] Reloaded with formic acid (0.3 mL), Ru(triphos)(tmm) (0.0025 mmol), Bi(OTf)3 (0.017 mmol), CPME (1 mL) after 16 h, 32 h reaction time. [c] 4,5‐Octanediol (89 % meso), butyroin (1.4 mmol). [d] TON and yield were determined by 1H NMR spectroscopy using mesitylene as internal standard.