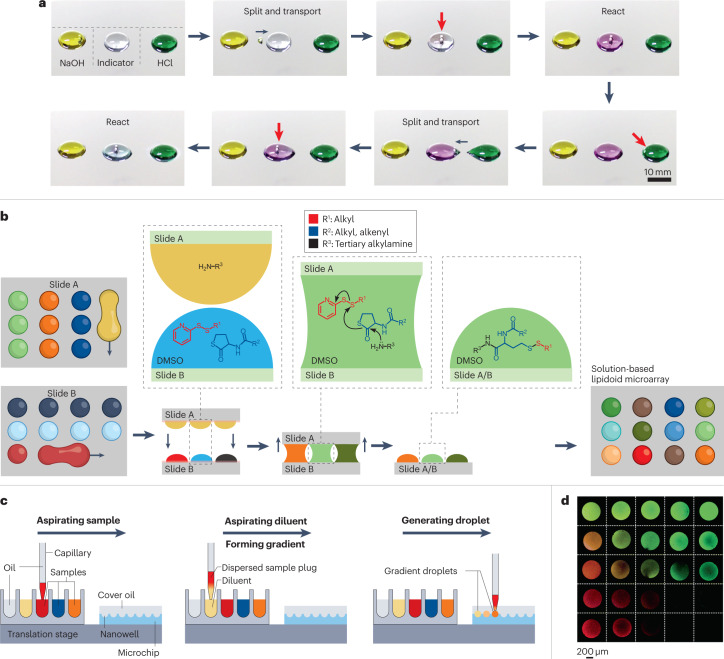

Fig. 4. Open droplet microfluidics for synthesis and combinatorial reactions.

An illustration of common workflows in open droplet microfluidic systems that minimize reagent consumption and enable parallel reactions. a, Magnetically actuated robots (that is, two steel beads), indicated by the red arrows, controlled by a magnetic control system, are programmed to manipulate droplets precisely for use in a sequential acid–base neutralization reaction. The robot is used to transport a daughter droplet from the NaOH droplet to the indicator droplet, which changes from colourless to purple, indicating that it is now alkaline. The robot then transports a daughter droplet from the HCl droplet to the indicator droplet, which returns to colourless as it is neutralized. b, An on-chip solution-based platform for compound synthesis and cellular screening (chemBIOS). A library of lipidoids is generated on-chip by sandwiching together slide A, which contains droplets of amines, and slide B, which contains mixtures of thiolactone and pyridyl disulfide derivatives dissolved in dimethyl sulfoxide (DMSO). Sandwiching the slides initiates the reaction between the reagents (shown in the expansions) to produce a microarray of different lipidoids. c, An automated microfluidic nanolitre-droplet gradient system for high-throughput screening. The three steps are aspirating the sample, aspirating the diluent to form the gradient and generating the droplet. This process leads to a sequence of droplets with a concentration gradient. d, A gradient droplet array for high-throughput screening of cellular responses to varying combinations of chemical and mechanical cues visualized with fluorescent dyes. Part a is reprinted with permission from ref. 35, AAAS. Part b is adapted from ref. 2 under a Creative Commons licence CC BY 4.0. Part c is adapted with permission from ref. 49, American Chemical Society. Part d is reprinted with permission from ref. 19, Royal Society of Chemistry.