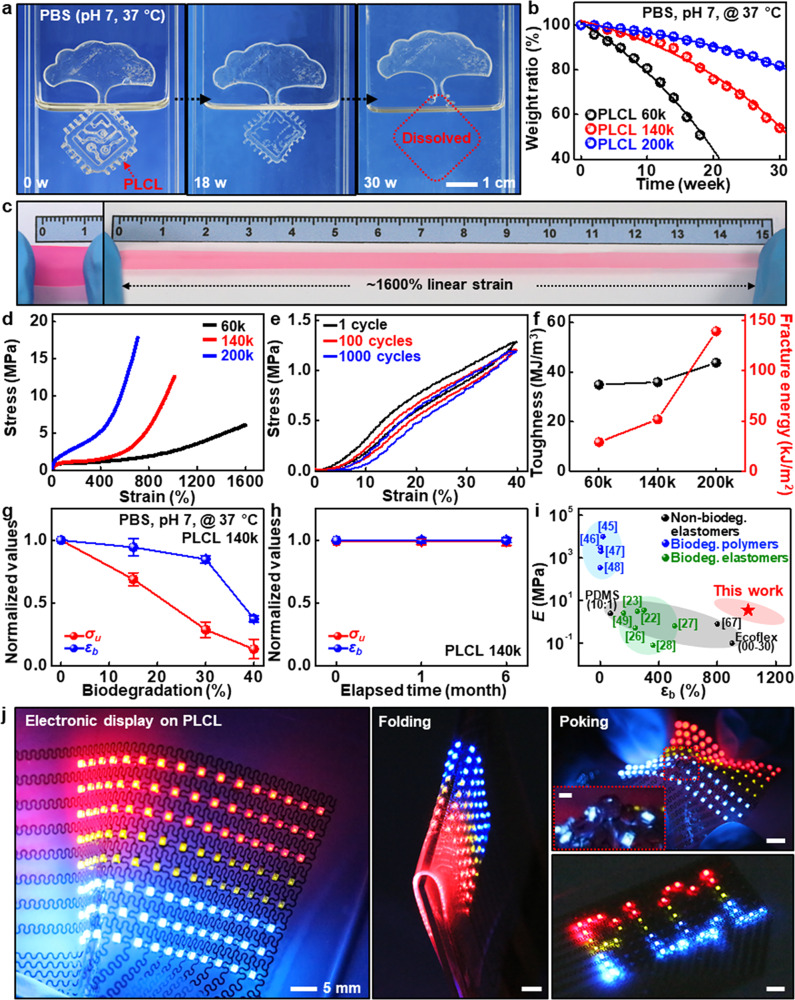

Fig. 2. Chemical, mechanical, and physical characteristics of PLCL elastomers.

a A series of optical images at several dissolution stages of a PLCL film (140k, 100 μm-thick) in phosphate buffer solution (PBS) (pH 7) at the physiological temperature of 37 °C. b Time-dependent changes in weight ratios of PLCL films as a function of molecular weight. c Super-elastic response of a colored, narrow PLCL elastomer (60k, 100 μm-thick, 20 × 10 mm) with a linear strain of ~1600%. d Stress-strain curves of PLCLs with different molecular weights (60k, 140k, and 200k). e Cyclic mechanical behaviors of PLCL elastomer (200k) under a uniaxial tensile strain of 40%, showing negligible stress-strain hysteresis. f Toughness and fracture energies of PLCLs (60k, 140k, and 200k), indicating the highest toughness and fracture energies among all biodegradable elastomers reported so far. g, h Normalized changes in the ultimate tensile strength (σu) and elongation at break (εb) of PLCL (140k) as a function of biodegradation (%) (g) and storage period in ambient conditions (h). Data are presented as mean values ± standard deviation. n = 3 independent samples. i Comparison of Young’s moduli (E) and elongations at break of PLCL elastomers (red) with those of widely used but non-degradable elastomers (black; PDMS, Ecoflex, and styrene-butadiene-styrene (SBS)64) and representative biodegradable polymers (blue) and elastomers (green). j Array (8×16) of individually addressable red, green, and blue (RGB) light-emitting diodes (LEDs) manufactured on PLCL substrates (left) upon various deformation modes of bending (middle) and poking (top right) and Arduino-powered scrolling LED letters, “PLCL” (bottom right).