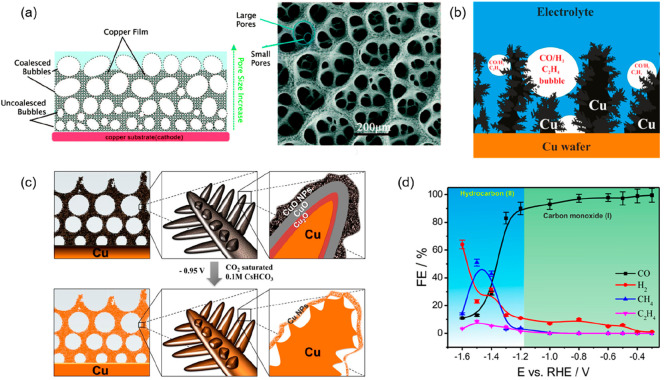

Figure 3.

(a) Schematic illustration and SEM image of a copper DHBT foam, demonstrating the hierarchical pore structure. Reproduced with permission from refs (30) and (43). Copyright 2015 Royal Society of Chemistry and 2013 IOP Publishing, respectively. (b) Schematic illustration of gaseous CO2R intermediates (CO and C2H4) and byproducts (H2) trapped within the porous Cu foam catalyst. Reproduced with permission from ref (41). Copyright 2016 American Chemical Society. (c) Schematic illustration of a dendritic CuO DHBT foam before (top) and after (bottom) CO2 electroreduction in 0.1 M CsHCO3, showing the material reduction to metallic Cu and the formation of nano-Kirkendall voids. Reproduced with permission from ref (47). Copyright 2019 Proceedings of the National Academy of Sciences. (d) Potential-dependent product distribution of the CO2RR using a Ag-DHBT foam catalyst by Faradaic efficiency, showing the formation of hydrocarbons at potentials more negative than −1.2 V vs RHE. Reproduced with permission from ref (33). Copyright 2018 American Chemical Society.