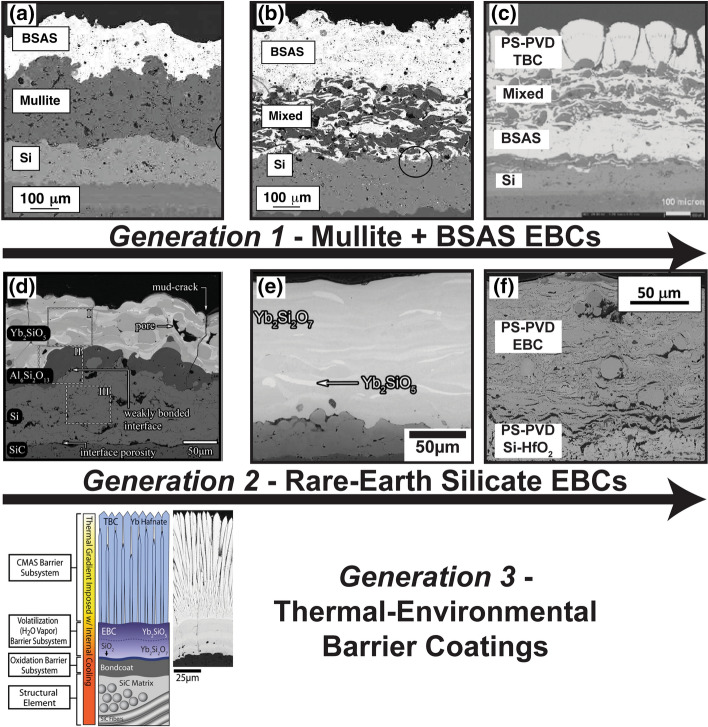

Fig. 11.

Progression of technology in thermally sprayed Thermal-Environmental Barrier Coatings. (a) Traditional BSAS-Mullite-Si EBC (b) Advanced BSAS + Mixed BSAS-Mullite + Si EBC (Ref 231). Used with permission of American Society of Mechanical Engineers (ASME), from Evaluating Environmental Barrier Coatings on Ceramic Matrix Composites After Engine and Laboratory Exposures, K.L. More, P.L. Tortorelli, L.R. Walker, J.B. Kimmel, N. Miriyala, J.R. Price, H.E. Eaton, E.Y. Sun, G.D. Linsey, Volume 4A, 2002; permission conveyed through Copyright Clearance Center, Inc. (c) First proposal of a thermal-environmental barrier coating, wherein a EBPVD TBC is deposited atop a similar structure to (b) (Ref 241). Used with permission of John Wiley & Sons—Books, from Thermal and Environmental Barrier Coatings for SiC/SiC CMCs in Aircraft Engine Applications*, I. Spitsberg, J. Steibel, International Journal of Applied Ceramic Technology, Volume 1, issue 4, 2004; permission conveyed through Copyright Clearance Center, Inc. (d) Ytterbium monosilicate EBC atop Mullite and a silicon bond coat (Ref 288). Reprinted from Journal of the European Ceramic Society, Volume 34, B.T. Richards, H.N.G. Wadley, Plasma spray deposition of tri-layer environmental barrier coatings, pp. 3069-3083, Copyright 2014, with permission from Elsevier. (e) Ytterbium disilicate EBC atop a silicon bond coat. The plasma-sprayed ytterbium disilicate coating is a heterogenous mixture of ytterbium disilicate and ytterbium monosilicate splats (Ref 289). Reprinted from Acta Materialia, Volume 106, Bradley T. Richards, Kelly A. Young, Foucault de Francqueville, Stephen Sehr, Matthew R. Begley, Haydn N.G. Wadley, Response of ytterbium disilicate–silicon environmental barrier coatings to thermal cycling in water vapor, pp. 1-14, Copyright 2016, with permission from Elsevier. (f) Advanced PSPVD EBC system which utilizes a modified Si-HfO2 bond coat for higher-temperature applications (Ref 242). The final structure of the envisioned Generation-3T-EBC is shown at the bottom. Reprinted from Journal of the American Ceramic Society, Volume 98, D.L. Poerschke, D.D. Hass, S. Eustis, G.G.E. Seward, J.S. Van Sluytman, C.G. Levi, Stability and CMAS Resistance of Ytterbium-Silicate/Hafnate EBCs/TBC for SiC Composites, pp. 278-286, Copyright 2015, with permission from Elsevier