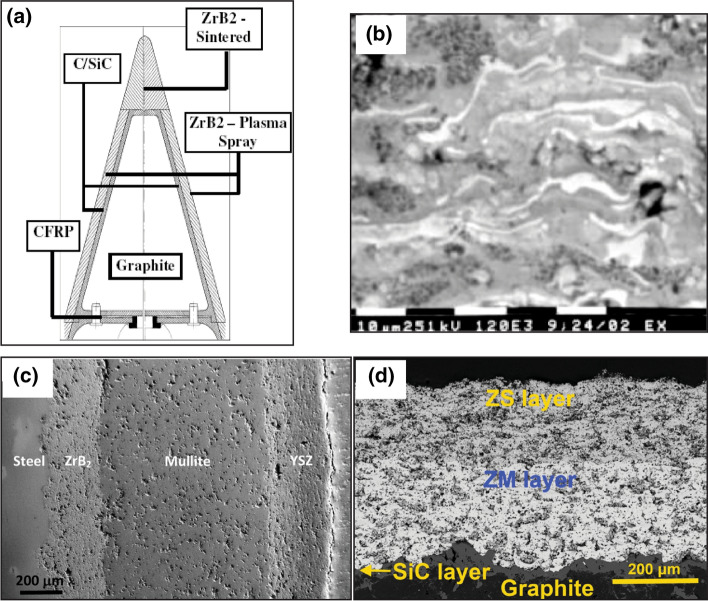

Fig. 12.

Evolution of UHTC ceramic coatings based on zirconium diboride. (a) The original prototype design for a ZrB2 plasma spray coating integrated into a nose cap configuration (Ref 273). Reprinted from Surface and Coatings Technology, Volume 155, Cecilia Bartuli, Teodoro Valente, Mario Tului, Plasma spray deposition and high temperature characterization of ZrB2-SiC protective coatings, pp. 260-273, Copyright 2002, with permission from Elsevier. (b) Shows a cross-section from the original CAPS fabricated ZrB2-SiC coating from (a) (Ref 274). Used with permission of American Institute of Aeronautics and Astronautics (AIAA), from PRORA-USV SHS: Ultra High Temperature Ceramic Materials for Sharp Hot Structures, L. Scatteia, A. Riccio, G. Rufolo, F. De Filippis, A. Vecchio, G. Marino, AIAA/CIRA 13th International Space Planes and Hypersonics Systems and Technologies Conference, 2005; permission conveyed through Copyright Clearance Center, Inc. (c) Shows a multilayer thermal spray coating design, integrating ZrB2 with Mullite and 7YSZ for added thermal protection and enhanced ablation resistance (Ref 278). Reprinted from Vacuum, Volume 88, M.F. Morks, Ivan Cole, Akira Kobayashi, Plasma forming multilayer ceramics for ultra-high temperature application, pp. 134-138, Copyright 2013, with permission from Elsevier. Finally (d) shows the two-layer ZrB2-SiC//ZrB2-MoSi2 coating, which showed marked improvements in ablation resistance due to the integration of an ablative-resistance ZrB2-SiC outer layer and a more stable ZrB2-MoSi2 inner layer (Ref 283). Reprinted from Corrosion Science, Volume 145, Tao Liu, Yaran Niu, Chong Li, Xiaohui Pan, Minhao Shi, Xuebin Zheng, Chuanxian Ding, Ablation resistance of ZrC-MoSi2/ZrC-SiC double-layered coating in a plasma flame, pp. 239-248, Copyright 2018, with permission from Elsevier