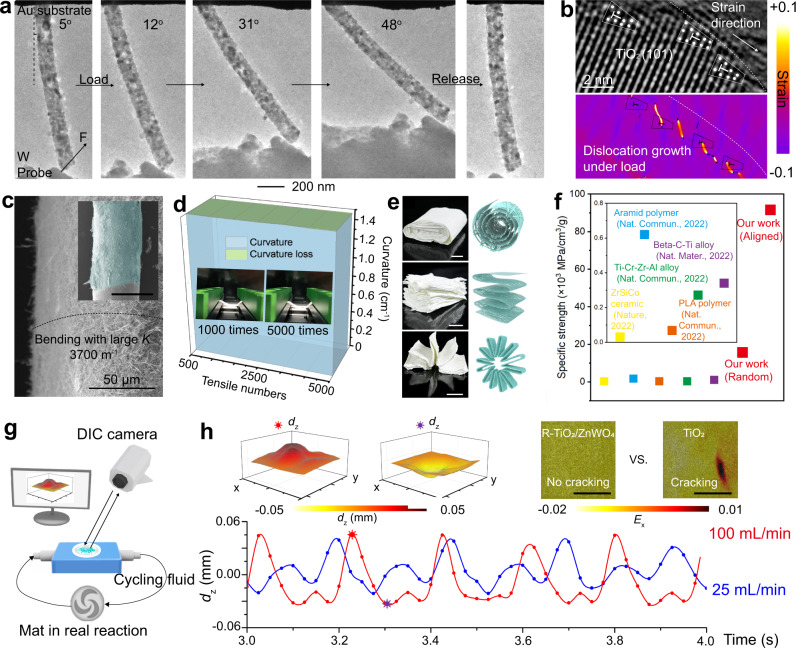

Fig. 3. Mechanical characterization of fibrous mat.

a In situ TEM observation of a single nanofiber under bending deformations. b TEM image showing the crack section of crystal under strain direction, with GPA strain analysis (inset). The color bar in (b) represents the strain. c SEM image of fibrous mat wrapped on an ultrathin tube with different magnifications. The scale bar in the inset SEM image is 1 mm. d Stability of mat over 5000-cycle bending with angle over 60o. e Optical images and corresponding schemes of the flexible TiO2/ZnWO4 mat with various origami structures. The scale bars represent 1 cm. f Comparison of specific mechanical strength among our work and recently advanced works. g Schematic illustration of DIC test for measuring micro-strain within a R-TiO2/ZnWO4 mat in the presence of flowing CH4 gas or electrolyte liquid. h DIC images (top) and real-time micro-strain curves (bottom) of the R-TiO2/ZnWO4 mat by cycling CH4/electrolyte with a flow rate of 100 mL/min. The DIC images show the absence of cracking in our mat while the conventional TiO2 mat has cracks. The scale bars in (h) are 0.5 cm. The color bars in (h) represent the dz (mm) detected in DIC tests. The red and purple symbol in (h) marked the peak and valley in curve, respectively.