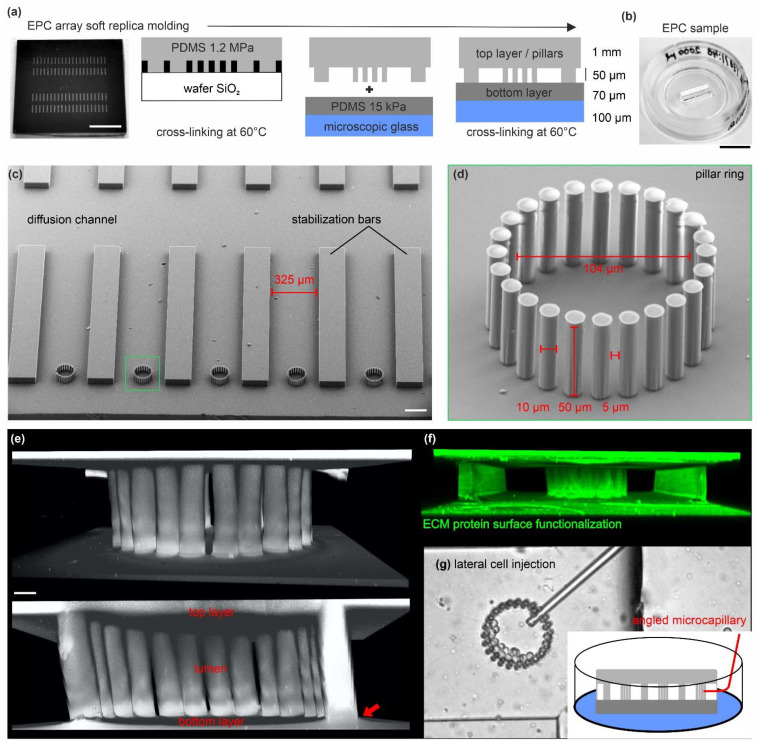

Figure 1.

Microfabrication of EPC arrays for 3D epithelial cell cultures: (a) Outline for the soft replica molding process to produce EPC arrays. A silicon wafer microstructured with SU-8 resist was used as mold cast for the pillar ring structures. The fabrication process is described in detail in the Section 2. Scale bar = 0.5 cm. (b) The PDMS silicone rubber topography is mounted in a microscopic glass slide for live cell imaging. A rubber strip with two rows of 20 arrayed pillar rings is used per dish. Scale bar = 1 cm. (c) Scanning electron micrograph shows the array topography (upside down orientation). (d) Detailed view on a ring structure with 24 high-aspect ratio pillars. Scale bar = 100 µm. The zoom-in micrograph highlights the high aspect ratio pillars. (e) 3D reconstructed image stack of a fully assembled ring structure confined by the planar bottom and top layers. The red arrow indicates the seamless material connection. The elastomer was stained with a hydrophilic fluorescent dye (DiD) for visualization. Scale bar = 10 µm. (f) A 3D reconstructed image stack of an EPC demonstrates the homogeneous ECM-surface functionalization with TRITC-labeled FN protein (20 µg/mL). (g) Images show lateral cell injection into a pillar ring using self-forged glass microcapillaries.