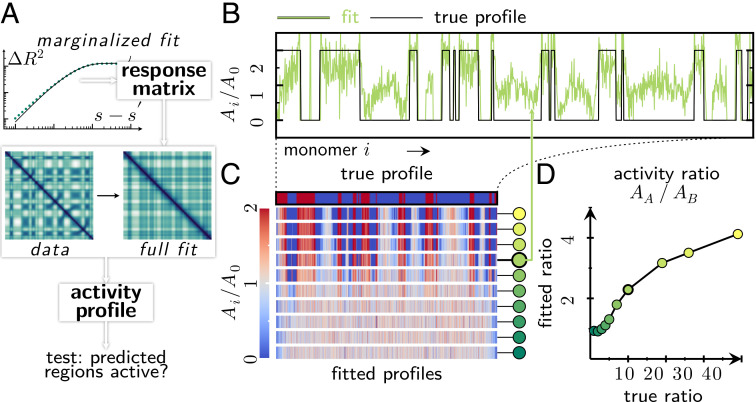

Fig. 4.

Inferring an activity profile based on structural data. (A) Data analysis workflow, which takes as input a heatmap with the pairwise mean squared separation between all monomers. First, we infer the mechanical properties of the homogeneous polymer on top of which activity differences will be imposed. We then propose a profile of activity that minimizes the mean squared error between the predicted mean squared separation map and the data. This workflow can be used to identify candidate active regions of the polymer, which could then be tested against alternative measurements. (B) We applied the workflow shown in A to simulated data on self-avoiding polymers driven by activity modulations in a spherical confinement (cf. Fig. 2F). We find, in general, good agreement between the inferred activity profile and the true profile used in the simulations. (C) The fitted activity profiles correctly identify the boundaries between active and inactive regions in the true activity profile. Color-coded circles next to the activity profiles correspond to the plot points (fitted activity ratios) in panel D; highlighted circle indicates activity profile in panel B. (D) The fitted activity ratio between active (A) and inactive (B) regions correlates with the activity ratios of the athermal excitations used in our simulations. In our linear model, a systematically lower activity ratio is sufficient to reproduce the folding patterns observed in the nonlinear simulations.