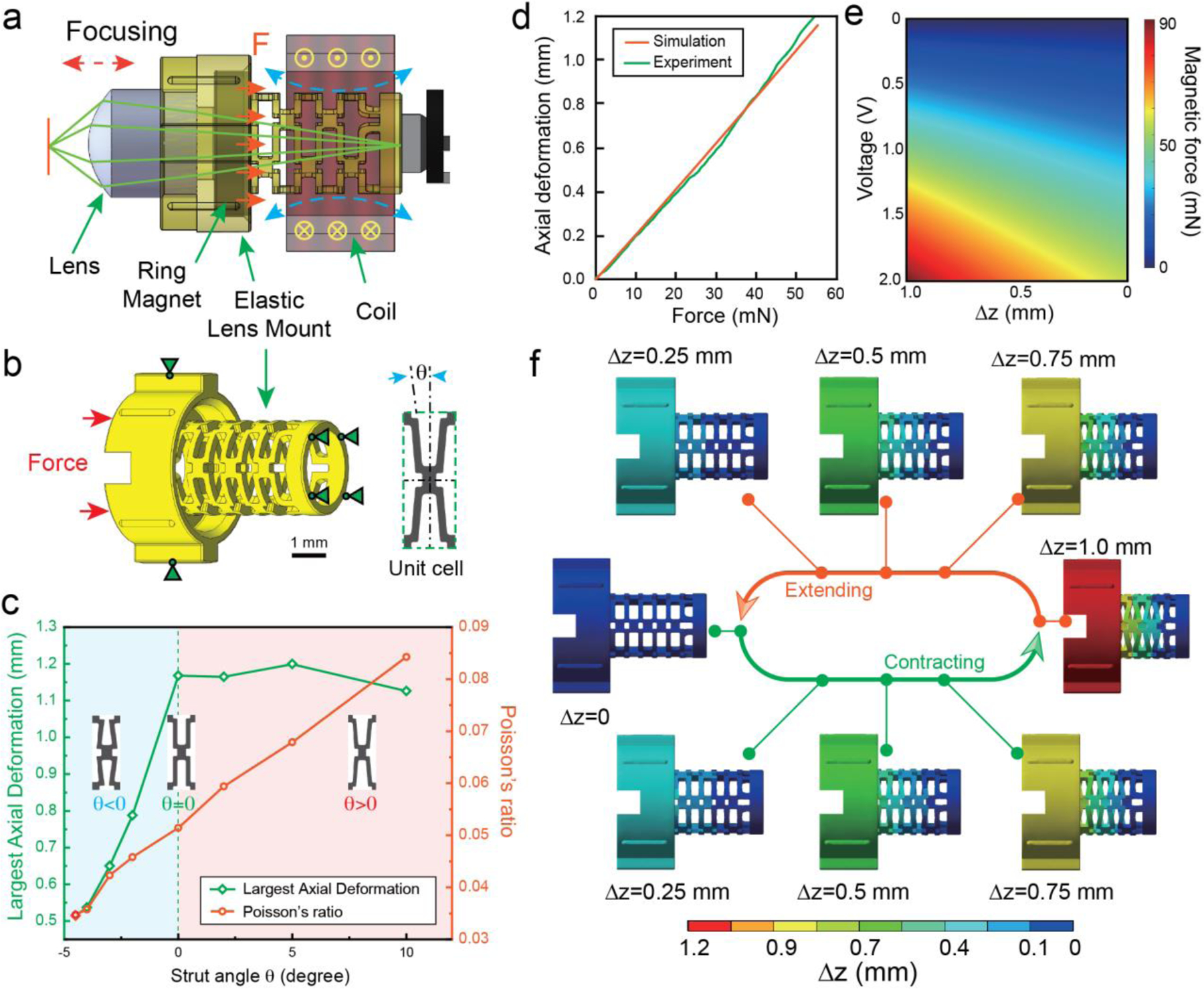

Figure 3. Working principle and optimization of the elastic lens mount.

a) Working principle of VCM. b) CAD model and boundary conditions of the elastic lens mount used for simulated compression testing in ANSYS. Scale bar: 1 mm. Insets: the unwrapped unit cell design illustrating the definition of strut angle. c) Comparison of maximum axial deformation and Poisson ratio for different lens mount designs. Insets: zoomed-in view of designs featuring negative, 0 and positive strut angles, respectively. d) Comparison of experimental and simulated elastic response of lens mount in compression tests. e) Magnetic force exerted on elastic lens mount as a function of axial distance and applied voltage. f) Axial displacement of the elastic lens mount during compression and extension.