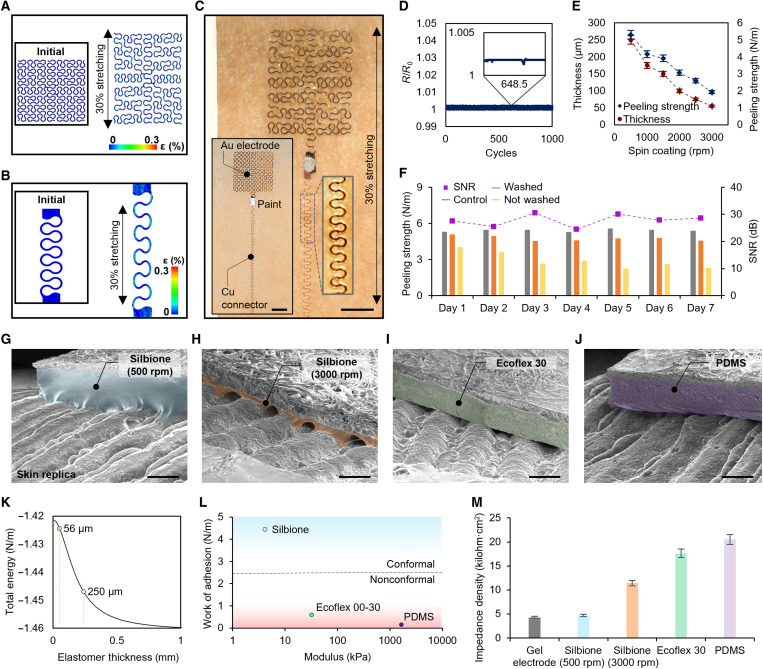

Fig. 3. Mechanical and material characterization of the wearable system.

Computational modeling results predicting mechanical stretchability (30%) of an Au electrode (A) and a Cu interconnector (B). (C) Photo of an electrode connected with an interconnector under stretching up to 30%, showing no adverse outcomes. Scale bar, 500 μm. (D) Change in electrical resistance of the integrated electrode in (C) throughout a cyclic stretching test (1000 cycles with 30% strain), demonstrating its reliability with a negligible change in relative resistance. (E) Change of a silicone adhesive (Silbione) in thickness and peeling strength according to its spin-coating speed (revolutions per minute). (F) Peeling strength and signal-to-noise ratio (SNR) values of a skin-mounted electrode during 7 days. Among them, a sample that is cleaned with soap daily maintains the skin-contact quality and mechanical reliability throughout the 7 days, such as the control sample. (G to J) SEM images of four substrates on a skin replica showing the quality of surface contact. Samples are made of different materials, including two silicone adhesive layers: spin-coated at 500 rpm (G) and spin-coated at 3000 rpm (H), Ecoflex 30 (I), and PDMS (J). Scale bars, 300 μm. Colorized areas show the coated soft materials on a fabric. (K) Plot of theoretical total interfacial energy depending on an elastomer thickness (Silbione). (L) Conformal contact analysis determined by work of adhesion and Young’s modulus. The dashed line represents the critical points deciding conformal or nonconformal regimes. (M) Impedance density measurements from various substrate compositions in (G) to (J), showing that the thin silicone adhesive layer in (G) offers conformal contact of a fabric-embedded electrode with the human skin. The contact quality of the dry substrate is similar to a conventional electrode with conductive gels.