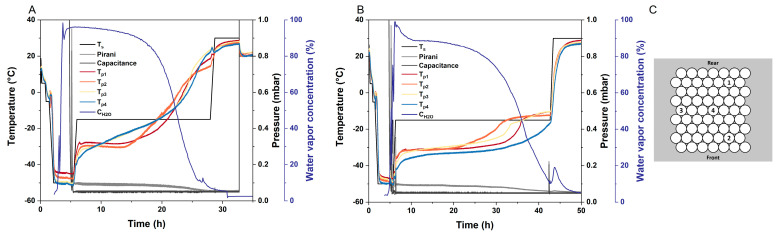

Figure 1.

Readouts of the drying processes of a 10% (m/V) sucrose formulation. Ts represents the shelf temperature; the chamber pressure is monitored via a Pirani gauge (Pirani) and an MKS Baratron gauge (Capacitance); Tp is the readout of the fiber optic temperature sensors; and the water vapor concentration (CH2O) during drying is recorded with a mass spectrometer. (A) Microwave-assisted freeze-drying was conducted at 2.43 GHz–2.48 GHz and 180 W. (B) Conventional freeze-drying was performed using the same lyophilizer. (C) Position of the four fiber optic temperature probes and arrangement of the vial package on the shelf.