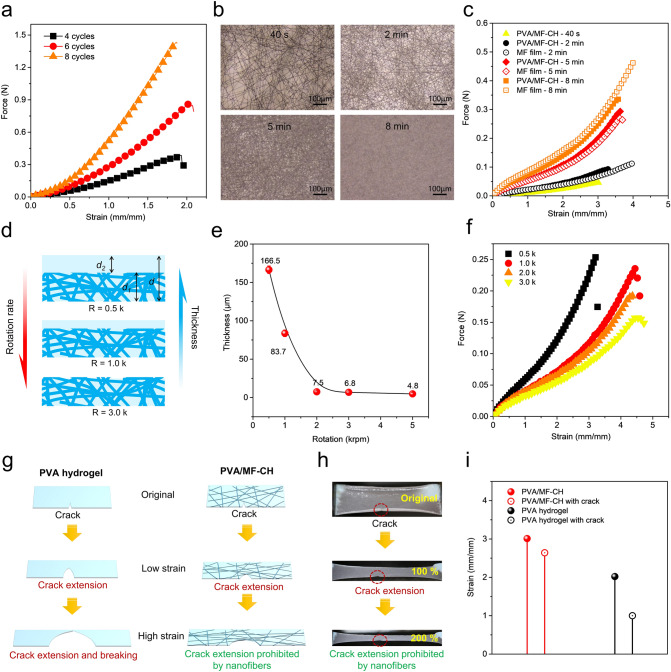

Fig. 2.

Mechanical properties of PVA/MF-CH. a Force-strain curve of the PVA hydrogel with different freeze-thaw cycles (4, 6, and 8). b Optical images of PU microfiber networks prepared with different electrospinning times (40 s, 2 min, 5 min, and 8 min). c Force-strain curves of PVA/MF-CH composed of PU microfiber networks with different electrospinning times (40 s, 2 min, 5 min, and 8 min) and PU microfiber networks with different electrospinning times of 2, 5, and 8 min. d Schematic thickness change of PVA/MF-CH with the increase of rotation rate. The thickness of the microfiber composite hydrogel (d) is comprised of the thickness of the microfiber network (d1) and the thickness of the PVA hydrogel over the microfiber network (d2) which can be controlled by the rotation rate during the spinning-coating procedure. e Thickness of PVA/MF-CHs processed under different rotation rates. f Force-strain curves of the PVA/MF-CH processed under different rotation rates of 0.5, 1.0, 2.0, and 3.0 k rpm. g Schematic anti-tearing behavior of microfiber composite hydrogel. h Digital images of PVA/MF-CH with a cut crack under different strains. i Maximum strains of PVA/MF-CHs and pure PVA hydrogels with and without a crack