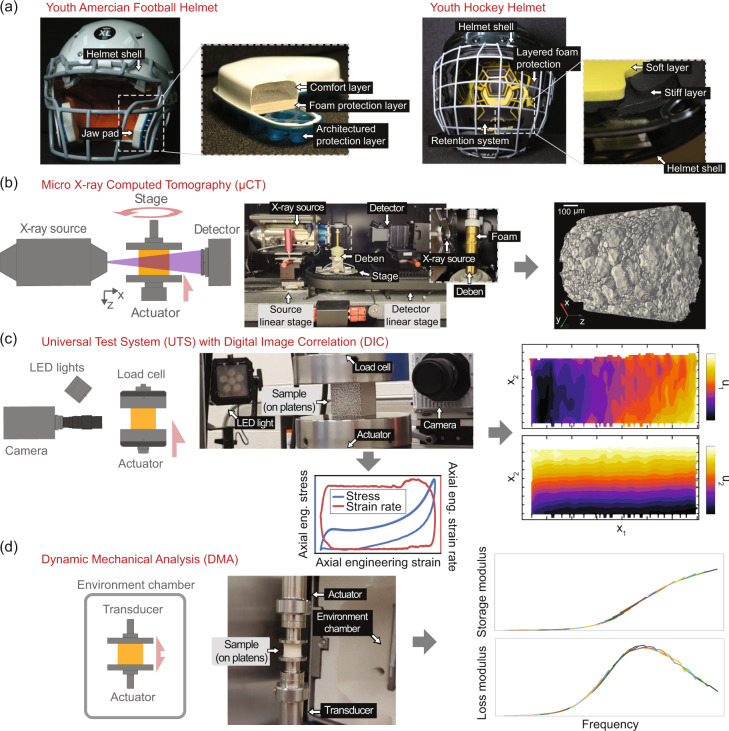

Fig. 1.

Schematics and photographs of equipment for the dataset and example data. (a) Examples of helmet liner applications for impact protection foams. Left A youth American football helmet with inset highlighting the multilayered pads that include two foams, a comfort layer and a stiffer vinyl nitrile foam protective sub-layer, above an architectured thermoplastic polyurethane backer. Right A youth hockey helmet with inset highlighting softer and stiffer impact protection foam layers. (b) Micro X-ray computed tomography laboratory-scale system, where the specimen is placed either on a freestanding platen (not shown) or inside the Deben load tube for in-situ compression (see inset). In either case these ride on a rotating stage and sequential exposures are taken. This allows the use of a tomographic projection algorithm to reconstruct a volumetric image (shown at right) of the specimen. (c) Displacement-controlled load frame with 2D digital image correlation system to measure stress-strain (shown at bottom) with full-field displacement (shown at right) and strain measurements at a range of applied strain rates. (d) Dynamic mechanical analysis using a paired-type transducer-actuator for small amplitude oscillatory strain, with the specimen epoxied between platens inside an environmental chamber, from which shifted time-temperature superposition data (shown at right) can be obtained.