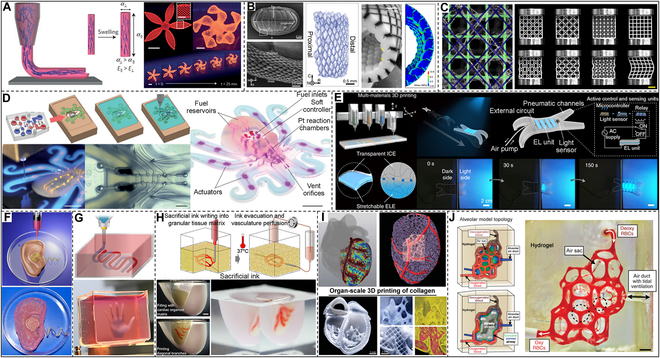

Fig. 12.

Macroscale additive manufacturing of bioinspired structures and materials. (A) 4D printing of biomimetic hydrogel composite. Reproduced with permission [274]. Copyright 2016, Springer Nature. (B) Multimaterial 3D printing of a synthetic flexible scale armor. Reproduced with permission [275]. Copyright 2019, Springer Nature. (C) Deep-sea sponge-inspired 3D-printed specimens of different lattice geometries. Reproduced with permission [278]. Copyright 2020, Springer Nature. (D) Full 3D printing of flexible robotic octopus. Reproduced with permission [286]. Copyright 2016, Springer Nature. (E) Chameleon-inspired 3D printing of soft robots integrated with flexible light-emitting and light-sensitive units. Reproduced with permission [289]. Copyright 2022, Springer Nature. (F) 3D-printed artificial ear. Reproduced with permission [291]. Copyright 2013, American Chemical Society. (G) Personalized hydrogel is used for 3D printing various types of tissues. Reproduced with permission [292]. Copyright 2019, Wiley VCH. (H) The embedded 3D bioprinting method created a heart tissue fragment. Reproduced with permission [293]. Copyright 2019, American Association for the Advancement of Science. (I) 3D bioprinting of collagen to design human heart components. Reproduced with permission [294]. Copyright 2019, American Association for the Advancement of Science. (J) 3D-printed artificial alveolus. Reproduced with permission [297]. Copyright 2019, American Association for the Advancement of Science.