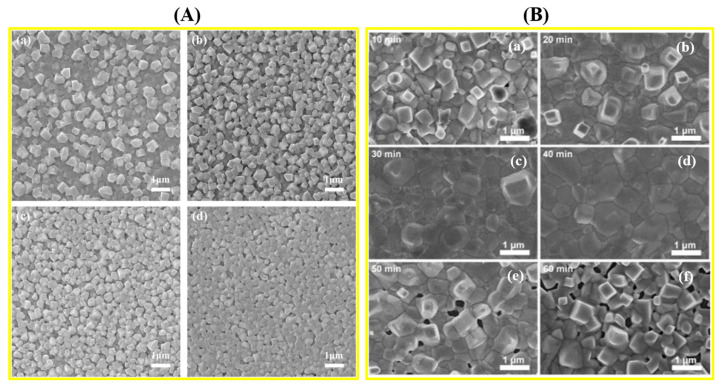

Figure 5.

(A) Scanning electron microscopic (SEM) image of CH3NH3PbI3 active layer (a) without Au-Ag-SnO2 core-shell nanocuboids (CSNCs), and with (b) 0.5% (c) 1.0% (d) 1.5% additives of Au-Ag-SnO2 CSNC. Without the addition of CSNCs, high surface roughness while adding slightly the roughness found to be removed and increase the compatibility with perovskite [116]. Reprinted with permission from Journal of Power Sources © 2019 Elsevier B.V. (B) The SEM images of PbBr2 coated electrode dipped into a precursor solution of CsBr/methanol at 50 °C for 10, 20, 30, 40, 50, and 60 min image (a–f). Increasing the immersion time from 10 min to 20 min, smaller sizes of grains appear. When the immersion time increases over 20 min to below 50 min, bigger grains are formed and decrease the roughness between the crystal. The pinholes appeared when the immersion period increased over 50 min [85]. Reprinted with permission from Applied Materials Copyright © 2018, American Chemical Society.