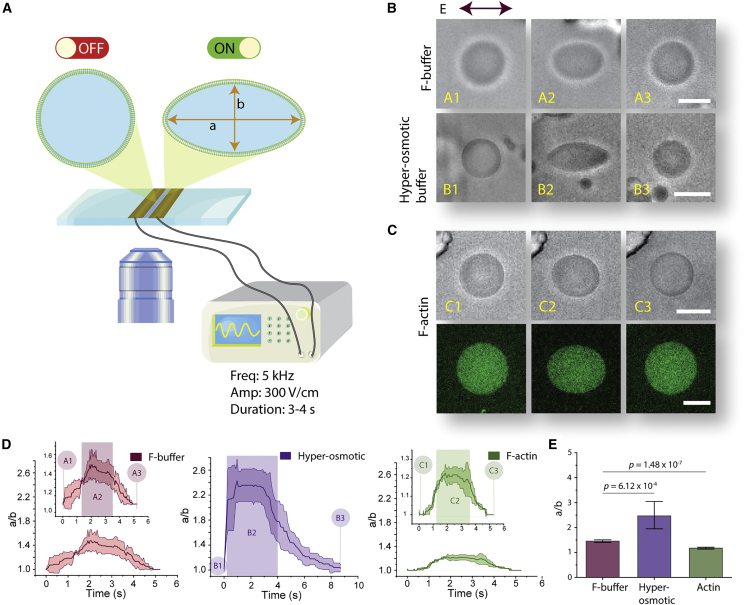

Figure 2.

Lumenal content of GUVs alters deformation profile when GUVs are subjected to electroperturbation. (A) Schematic of the electrodeformation setup mounted on an inverted microscope. A function generator is operated at 30 kV/m at 5 kHz, and a sinusoidal wave was applied for a duration of 3–4 s. Schematic shows electrodes adhered onto a coverslip. GUVs transform from a spherical shape to an ellipse when the electric field is applied. (B) GUV deformation is dependent on osmolarity difference between inner and outer solutions. (Top) Bright-field images of electric-field-induced shape transformation of actin-polymerization-buffer GUVs. (A1) GUV at an undeformed state prior to AC field application. (A2) Steady-state deformation of GUVs during electoperturbation. (A3) Actin-polymerization-buffer GUV after electrodeformation recovery. (B1–B3) Electrodeformation of actin-polymerization-buffer GUV in a hyperosmotic condition (flaccid GUV). (B2) shows exaggerated prolate deformation with pointed ends. (C) Electrodeformation of an F-actin GUV. (C2) shows visually apparent dampened deformation compared with (A2) and (B2). (C, bottom) Representative fluorescence image of F-actin GUV labeled with ATTO 488 actin. (D) Deformation profile of GUV conditions in (B) and (C) for F-buffer, hyperosmotic buffer, and F-actin conditions, as indicated. Labels (A1, A2, A3 … etc.) correspond to GUV transformation stages during electroperturbation. Shaded rectangular box denotes approximate duration of electric field application. Shaded areas in the traces in each of the plots indicate ±SD, n = 3. (E) Comparison and statistical analysis of maximum GUV deformation of each GUV condition as indicated. Data represent mean maximum deformation, and error bars denote ±SE. nbuffer = 11, nhyper = 14, and nactin = 12. Scale bars, 10 μm. To see this figure in color, go online.