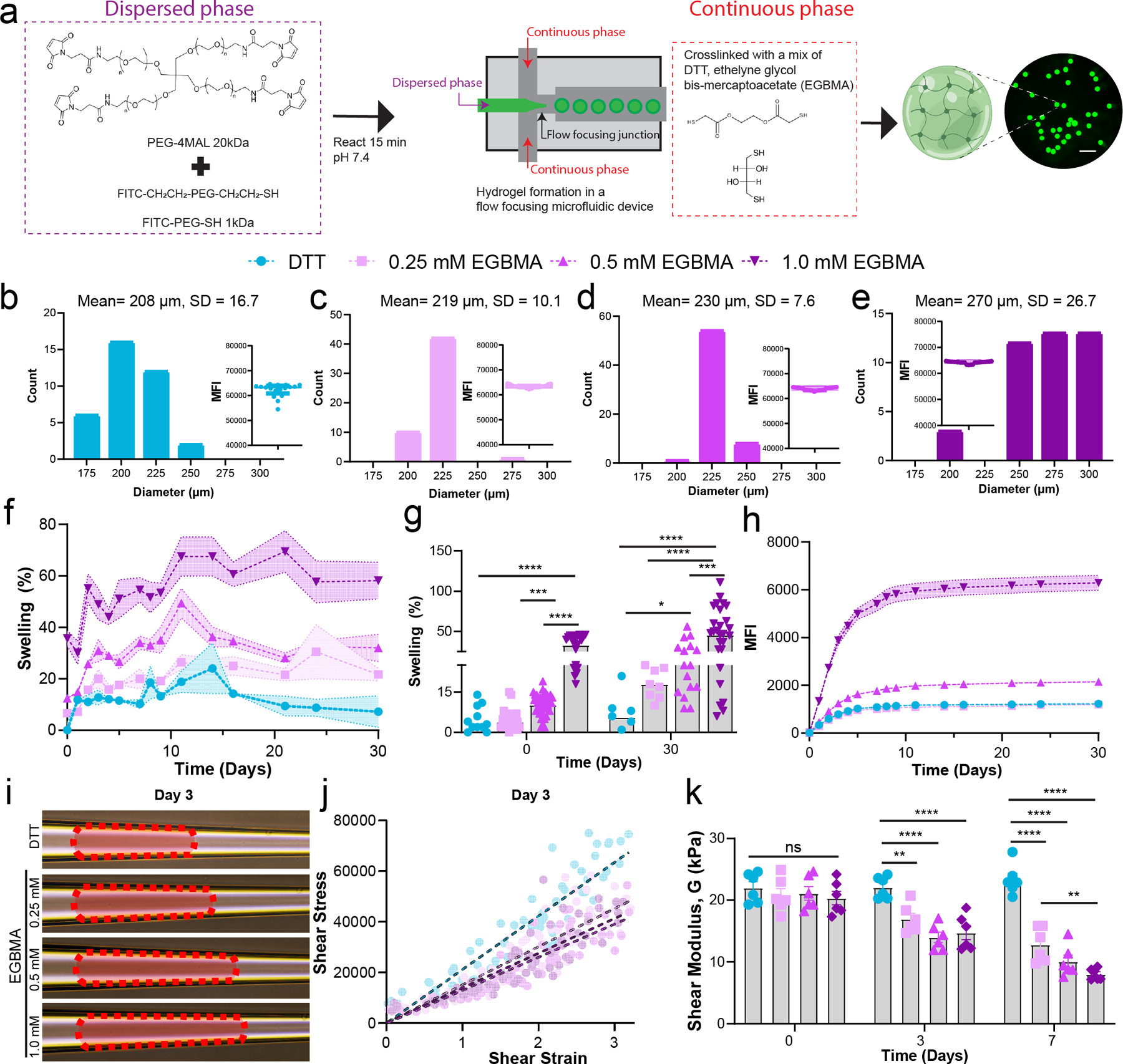

Figure 1.

Hydrolytically degradable microgels can be fabricated by the addition of ester-containing dithiol crosslinkers. a) PEG-4MAL macromer is modified with linear PEG FITC and segmented through a flow-focusing microfluidic chip with a continuous phase containing small dithiol molecules, DTT and EGBMA. This results in monodisperse microgels that can be fluorescently tracked. Scale bar 1 mm. b–e) Size distribution of microgels based on EGBMA concentration in the oil phase. Inset represents the intensity of individual microgels post-fabrication, demonstrating similar modification of the macromer backbone with the linear PEG-FITC tracker, minimum n = 36, pooled from 3 independent microfludic runs. f,g) Microgel swelling in an aqueous buffer is directly proportional to the molar concentration of EGBMA linker in the crosslinking phase, minimum n = 6 per sample. h) Tracking of released PEG-FITC in solution is dependent on EGBMA concentration in microgels. i) Day 3 images of microgels deformed by an applied pressure in a tapered microcapillary. j) Shear stress versus strain for confined microgels fabricated with varying concentrations of EGBMA after 3 days of incubation in an aqueous buffer, n = 6, >60 points total. k) Quantification of shear modulus of all microgel formulations after different time exposures to aqueous buffer, n = 6. All data presented as average ± s.e.m. unless otherwise stated, swelling data analyzed using a mixed-effect model, with Tukey correction for multiple comparisons; Shear modulus was analyzed with a two-way ANOVA with Tukey corrections for multiple comparisons. * p < 0.05, **p < 0.01, ***p < 0.005, ****p < 0.0001.