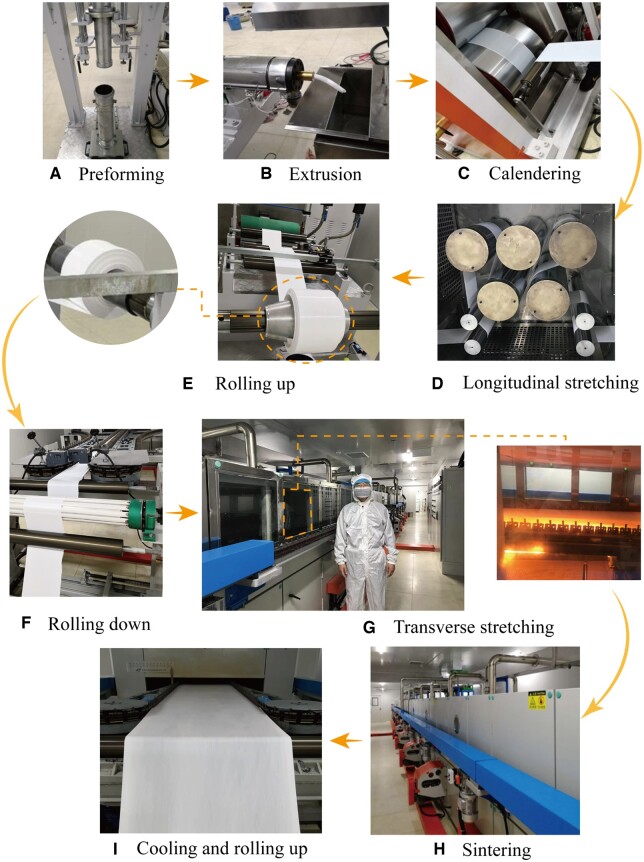

Figure 2.

The manufacturing process of ePTFE membrane. (A) Preforming to compress the compound of PTFE fine powder and lubricant and remove the air in the compound. (B) Paste extrusion to make a rod by the press extruder machine from the preform. (C) Calendaring to make a primary tape from the rod by a twin-roller calendaring machine. (D) Longitudinal stretching. In this procedure, the primary tape was stretched several times by the rollers with different rotation speeds. (E) Rolling up the tape by a mandrel. The right is an olive roller and the left is a common cylinder roller. (F) Rolling down of the tape at the entry of the transverse stretching machine. (G) Transverse stretching. The left is an overview of the machine with the corresponding author of this article reflecting the size of our industry-scale facility, and the right is an inner view within the transverse stretching oven. (H) Sintering to fix the shape of the biaxial stretching of membrane. (I) Cooling and rolling up of the biaxial stretching ePTFE membrane.