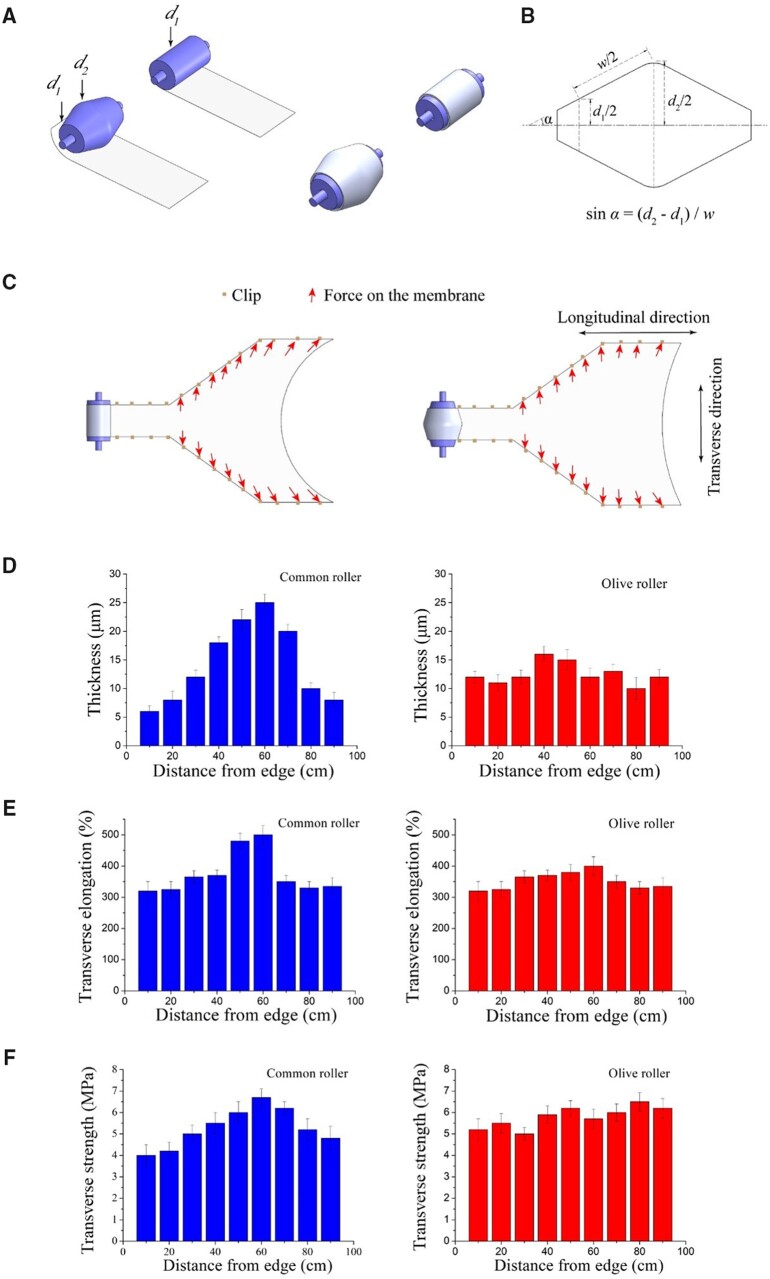

Figure 3.

Diagram of using an olive roller to roll up the PTFE tape in the longitudinal stretching and then roll down in the transverse stretching to reduce the ‘bowing effect’ with the longitudinal contraction of the ePTFE membrane when both sides are grasped by the clips. (A) Comparative diagram of a common roller with a cylinder shape and an improved roller with an olive shape. The olive roller rolls up the PTFE tape on its surface in the rolling process, which will make the middle tape length longer than the side since the middle diameter (d2) is greater than the side diameter (d1). (B) An axial section diagram of an olive roller. Where ‘α’ is the angle between the roller surface and the axis and ‘w’ is the width of the tape wound around the roller. The ratio of the middle length to the edge length of the tape wound on the olive roller is d2/d1. (C) Comparative diagram of an olive roller and a common roller during rolling down in the transverse stretching process. During the transverse stretching, because the edges of the membrane are fixed by the clips and the longitudinal shrinkage of the membrane, the middle of the membrane will retract and form an arch shape at the beginning of the membrane (bowing effect). using an olive roller can reduce the bowing effect in transverse stretching because it can relieve the longitudinal contraction in the middle of the membrane. (D) The effect on the membrane thickness when stretching with a common roller and an olive roller. The transverse width of the membrane is 100 cm. A total of nine sampling points are along one side to the other side in the transverse direction. (E) The effect on the membrane transverse elongation when stretching with a common roller and an olive roller. (F) The effect on the membrane transverse strength when stretching with a common roller and an olive roller.