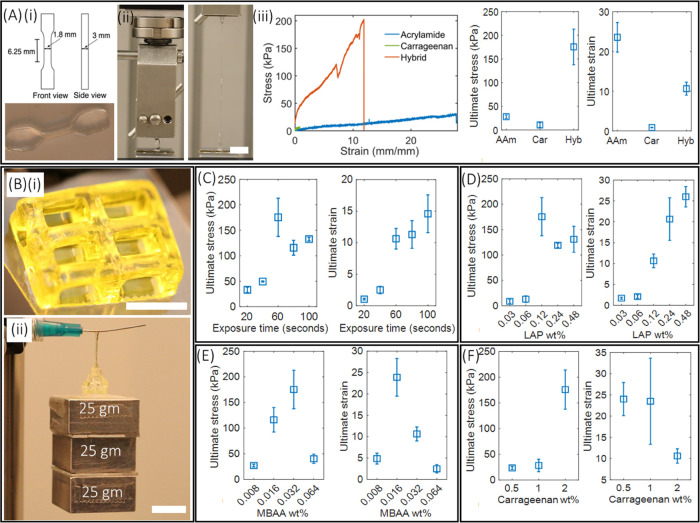

Figure 3.

(A) (i) Schematic and printed dog-bone structure using a hybrid gel structure with a laser power of 2.17 mW/cm2 and an exposure time of 60 s. (ii) Photographs showing the performance of dog-bone structure during tensile testing, and the structure stretched 9.5 times its original length. (iii) Stress–strain plot obtained from dog-bone structures printed using the DN gel, acrylamide-only gel, and carrageenan-only gel. Ultimate stress and ultimate strain of the fabricated structures are also depicted. (B) (i) 3D-printed hollow-lattice geometry with a structure for studying the tensile performance (scale bar—5 mm). (ii) Photographs showing the tensile performance of the structure (scale bar—8 mm). (C–F) Ultimate stress and ultimate strain of DN gel structures printed by varying exposure times, and amounts of the photoinitiator, cross-linker (MBAA), and κ-carrageenan.