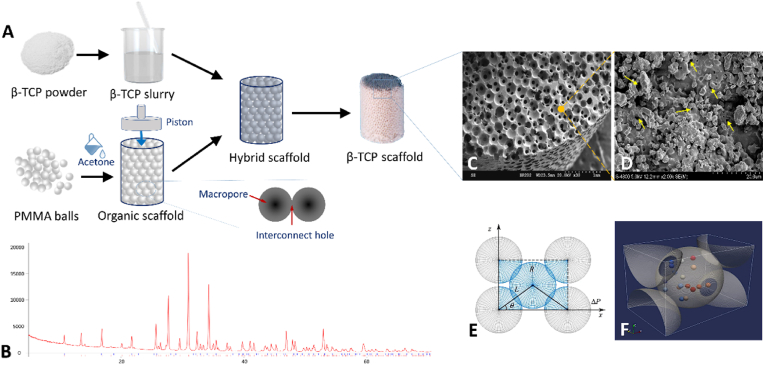

Fig. 2.

Preparation of porous β-TCP scaffold and its main characteristics. A. The method of spatially controlled molding by the slip-casting process for porous β-TCP scaffold preparation; B. X-ray diffraction (XRD) patterns of the β-TCP scaffold. C. A three-dimensional view of the highly interconnected structure in the porous β-TCP scaffold taken by scanning electron microscopy (SEM); D. SEM image showing the micropores (with the size of 200 nm–1000 nm) of the matrices of porous β-TCP scaffold. The yellow arrows indicate the location of micropores. E-F. Schematic diagram of the “basic repair unit”. (E) The “basic repair unit” generated by theoretical calculations. Each pore contacted the adjacent four surrounding pores in a single plane. Such an interconnected structure could be parameterized by the ball center distance (L), the radius of balls (R), and the included angle (θ); (F) Stereo view of the repair unit, cells (marked as colored pellets) moved from one pore to another through the interconnected holes and deposited on the concave pore walls, forming the bed of seeds for tissue regeneration.