Abstract

In pulsed electric field (PEF) method sources of high voltage pulses are placed amid two electrodes in to fluid or paste type foods. Electricity is passed between two electrodes to sterilize the food.

Almost all PEF technology entails the use of this technology in milk and milk product processing, eggs, poultry, juices and other liquid foods to prevent microorganisms. PEF technology, one of the promising methods of non-thermal preservation of food, can address the biological hazards efficiently.

Recently available research papers explored PEF technology not only to facilitate the inactivation of microorganisms but also to alleviate the pressing competence for juice extraction purpose from plants for food application and also to intensify the drying and dehydration process of food.

Most of the literatures are available on killing of microorganisms using PEF technology but the reports on influence of PEF technology on quality parameters of food after treatment and about their acceptability are limited. Now the technology is becoming popular and many recent papers reported about better yield and excellent quality of nutrient extracted by using PEF technology.

Keywords: Pulsed electric field (PEF), Food preservation, Liquid foods, Microbial inactivation, Drying of foods

1. Introduction

Presence of physical, chemical and biological hazards make the food unsafe for the consumers. Among them biological hazards which mainly include food-borne pathogens may be considered as principal hurdle for food preservation. Pulsed electric field (PEF) technology, one of the promising methods of non-thermal preservation of food, can address the biological hazards efficiently. In this technique, high intensity electric field with pulse (μs) amplitude from the range 100–300 V/cm to 20–80 kV/cm is generated between two electrodes and applies to a product for short duration (from milliseconds to microseconds) to inactivate the microorganisms below the thermal processing temperatures. In contrast to conventional heat treatment, PEF treatment causes negligible deteriorative effect on color, flavour, taste and nutrients of food materials [[1], [2], [3], [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15]] (see Table 1).

Table 1.

Effect of Pulse Electric Field Technology on Food Enzymes. (Taken and modified from (Bayindrili, 2010) [10].

| Enzyme | Enzyme and buffer solution/medium | Processing condition | Enzymes stability |

|---|---|---|---|

| Lipoxygenase (LOX) | Green bean juice | Mono polar mode; electric field strength: 2.5–20 kV/cm; pulse width: 1 μs; pulse numbers: 100 to 400; pulse frequency: 1 Hz | No inactivation |

| Soymilk | Bipolar mode; electric field strength: 20–42 kV/cm; pulse width: 1–5 μs; treatment time for up to 1036 μsc | Irreversible inactivation Max. inactivation: 88% treated at 42 kV/cm for 1036 μs with 400 Hz of pulse frequency and 2 μs of pulse width at 25 °C | |

| Soymilk | electric field strength: 20, 30, and 40 kV/cm; treatment time: 25, 50, and 100 μs; pre-treatment heating temperatures: 23, 35, and 50 °C | Irreversible inactivation Max. inactivation: 84.5% at 40 kV/cm for 100 μs with preheating at 50 °C | |

| Tomato juice | bipolar mode; 4 co-field tubular treatment chambers; electric field strength: 0–35 kV/cm; treatment time: 20–70 ms; pulse width: 3 μs; PEF treatment temperature: 10–50 °C; flow rate: 1 mL/s; pulse delay time: 20 μs | Irreversible inactivation Max. inactivation: 80% treated at 35 kV/cm for 50 or 60 ms at 30 °C. | |

| Tomato juice | bipolar mode; 6 co-field tubular treatment chambers; electric field strength: 40 kV/cm; treatment time: 57 μs; pulse width: 2 μs; temperature before PEF treatment: 45 °C (temperature increase of 8 °C during treatment) | Irreversible inactivation Max. inactivation: 54% | |

| Papain | Commercial purified papaya papain initially activated by reducing agents (cysteine 20 mM and DTT 5 mM) and diluted in 1 mM EDTA | electrical field strength: 20, 30, 40, and 50 kV/cm; pulse width: 4 μs; continuous system; flow rate: 0.77 ml/s; pulse numbers: up to 1500 | Irreversible inactivation Max inactivation: up to 40% immediately after PEF treatment at 50 kV/cm and 500 pulses |

| Pectinmethylesterase (PME) | Commercial purified orange PME, details on medium and enzyme concentration not completely described | Exponential decay pulse; coaxial and parallel-plane treatment chamber, electric field strength: 5–25 kV/cm; treatment time: 0.5–15 μs; pulse frequency: 1 Hz, pulse numbers: 207 to 1449 | Irreversible inactivation Max. inactivation: 17% and 16.46% in coaxial cylinder and parallel-plane chamber, respectively, treated at 207 pulses of 25 kV/cm |

| Partiallya purified banana, carrot, orange and tomato PME dissolved in Tris buffer (20 mM; pH 7.0) | electric field strength: 13.2 and 19.1 kV/cm; treatment time: 1.6 ms; pulse frequency: 0.5 or 5 Hz | Irreversible inactivation Max. inactivation: 45% (banana), 83% (carrot), 87% (orange and tomato) | |

| Pectinex 100 Lr (Novo Nordisk Ferment, Neumatt, Switzerland) in distilled water at 5% mass fraction; electrical conductivity: 11.48 S/m, pH 4.73 | Square wave pulse; pulse width: 40 μs; electric field strength: 5–24 kV/cm; total treatment time: 16 ms; pulse frequency: 0.5 or 5 Hz | Irreversible inactivation Max. inactivation: approximately 95–98% treated at 5 kV/cm for 16 ms; 12 kV/cm for 8–12 ms; 20 kV/cm for 6–8 ms and 24 kV/cm for 4 ms | |

| Desalted pectinex 100 Lr (Novo Nordisk Ferment, Neumatt, Switzerland) diluted in bi-distilled water (1:5 v/v); pH 4.6 | Exponential decay pulse; monopolar mode; electric field strength: 19, 25, 30, 33, 36 and 38 kV/cm; inlet temperature: 4 °C; pulse numbers: 10 to 100 | Irreversible inactivation Max. inactivation: approximately 86.8% treated at 38 kV/cm for 340 μs | |

| Grape fruit juice | Monopolar mode, electric field strength: 20, 30, and 40 kV/cm; preheating at 23, 35, and 50 °C; 15 Hz; pulse width: 1 μs; treatment time: 25, 50, 75, and 100 μs | Irreversible inactivation Max. inactivation: 96.8% obtained using a combination of preheating to 50 °C, and a PEF treatment time of 100 μs at 40 kV/cm | |

| (Valencia) orange juice | monopolar mode; inlet temperature <40 °C; pulse width: 1.4 μs, pulse frequency: 600 Hz; electric field pulse: 20–35 kV/cm; treatment time 59 μs | Irreversible inactivation Max. inactivation: 90% treated at 35 kV/cm for 59 μs | |

| (Valencia) orange juice | Six co-field tubular chambers (diameter 0.635 cm); electric field pulse: 35 kV/cm; treatment time 59 μs | Irreversible inactivation Max. inactivation: 88% | |

| (Valencia) orange juice | bipolar mode; inlet temperature 10–50 °C; pulse frequency: 700 Hz; electric field pulse: up to 35 kV/cm; treatment time up to 250 ms | Irreversible inactivation Max. inactivation: 90% treated at 25 kV/cm and 50 °C for 250 ms | |

| Orange juice | monopolar pulse; 1000 pulses; pulse width: 1 μs; pulse frequency: 1 or 2 Hz; electric field strength: up to 35 kV/cm | no inactivation but increase in activity probably due to cell permeabilization and release of intracellular pectinmethylesterase | |

| (Navelina) orange juice | bipolar mode; temperature <40 °C; pulse width: 4 μs, pulse frequency: 200 Hz; electric field pulse: 35 kV/cm; treatment time 1 ms; energy input of 5390 MJ/m3 | Irreversible inactivation Max. inactivation: 81.6% | |

| Orange juice | mono- or bipolar mode; electric field strength: 5, 15, 25, 30, and 35 kV/cm; treatment time: 100, 300, 600, 1000, and 1500 μs; pulse width: 4 μs; pulse frequency: 200 Hz. | Irreversible inactivation Max. inactivation: 80% treated at 35 kV/cm for 1500 μs with 4 μs bipolar pulses at 200 Hz without exceeding 37.5 °C | |

| (Valencia) orange juice-milk beverage | bipolar mode; six co-field chambers; pulse width: 2.5 μs; treatment time: 50 μs; electric field strength: 30 kV/cm | Irreversible inactivation Max. inactivation: 90% |

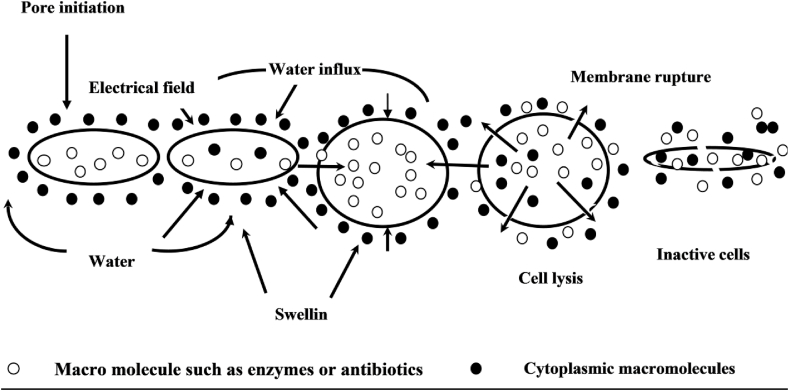

Although the authentic mechanisms of deterioration of microorganisms by means of PEF are not recognized but it is established that rapture of microbial membranes leads to inactivation of microorganisms in PEF processing of foods (Figure [1]).

Nowadays non-thermal processing has attained a considerable importance because of the rising interest of food with elevated nutritional value with fresh appearance, demonstrating a substitute of conventional heat processing and Microwave processing. PEF is a promising technique which has been generally considered as non-thermal preservation technology for food. Worldwide this recent technology has been studied by several researchers to sterilize liquid juices like apple and oranges. The sensory characteristics of juices are very well conserved and taste-wise similar as freshly extracted and the shelf lives are enhanced after processing. Numerous researches have been done to preserve apple, orange, carrot, tomato juices, milk and milk products, pea soups, liquid whole eggs and egg products [[16], [17], [18], [19], [20]].

During food preservation, conditions are manipulated in such a way that growth of microorganisms is prohibited by arresting the optimum conditions (temperature, pH, water activity, additives quantity etc.) of microbial growth but they can grow as soon as the conditions are suitable [[21], [22], [23], [24], [25]].

Usually PEF technique is useful for pasteurization of miscellaneous liquid food commodities such as juices, milk, liquid eggs etc. To improve the output of PEF, sometime it is useful to apply hurdle technology i.e along with PEF other cold preservation techniques e.g. ultrasound, high pressure processing and ultraviolet light treatment [[26], [27], [28], [29], [30]].

2. Fundamentals and principle of PEF technology

This technology is dependent on the quantity of pulses conveyed to the product, generated in between a pair of electrodes. A definite space is maintained amid the two electrodes, recognized as handling distance of the compartment. Throughout PEF operation, high voltage is used eventually resulting prevention of microbial growth exists in the food material. Occurrences of electric field such as various exponentially decayed emissions, bipolar waves or oscillatory pulsates are applied. The method is run at diverse temperature ranges such as at ambient, below ambient and above the ambient temperatures. PEF treated packed food is stored under refrigeration environment [[31], [32], [33], [34], [35], [36], [37], [38], [39]]. As the food consists of various ions including precise field potency of electrical conductivity in the treated product thus the progress of electric pulse in the liquid food media is promising in PEF preservation techniques. PEF is generally favoured for liquid foods as the electrical current move more effectively inside the liquid food. Transmission of pulses from start to end point as in liquid system movement is comparatively easy due to the survival of charged molecule’s occurrence in the liquid [[40], [41], [42], [43], [44], [45], [46], [47], [48], [49], [50], [51], [52], [53], [54]]. Sitzmann et al. (2016) assured that the method used in PEF technique is the release of produced pulse power which is positioned linking two electrodes, reducing the effectual distance in the PEF treatment chamber [55]. An elite PEF deal has pulse maker that produce high voltage pulses, action compartment holding the innovation to be taken care of and associated with the control along with the monitoring systems. Food manufactured is positioned within the treatment chamber includes electrodes associated with each other with subject to non-conductive in character to avoid to pass the current from start point till the end. High voltage electrical pulses are formed with the purpose to restructure the product. The resulted end product positioned in between the pair of electrodes experience force per unit charge that disintegrate cell membranes of bacteria [[56], [57], [58], [59], [60]].

3. PEF treatment and mechanisms

The essential standard of the PEF technique is the utilization of small pulses of elevated electric fields within the period of micro to milli seconds and the range of strength was 10–80 kV/cm. Treatment duration is regarded by multiplying number of pulses with efficient pulse duration. In this method pulsed electrical current transmitted to the end product located in the midpoint among a pair of electrodes, sustaining a definite gap between electrodes known as the handling gap in the PEF compartment. The applied high voltage eventually produces an electric charge consequently resulted destruction of microorganisms. For exponentially decaying circumstances the electric charge might be useful for bipolar, square wave, or oscillatory pulses at or below or above the ambient temperature. Post treatment, the food is aseptically packed at low temperature (freezing temperature) condition and it is maintained throughout the storage. Usually electric pulse is flown through a food material and is maintained in between a pair of electrodes in a compartment at room temperature. Food is able to transfer electricity due to the incidence of numerous ions, permitting to generate a specific level of electrical conductivity. Thus, when an electrical field is useful, electrical current is allowed to pass through the food especially liquid and is agitated at every point in the food due to the incidence of charged particles [[61], [62], [63], [64], [65]].

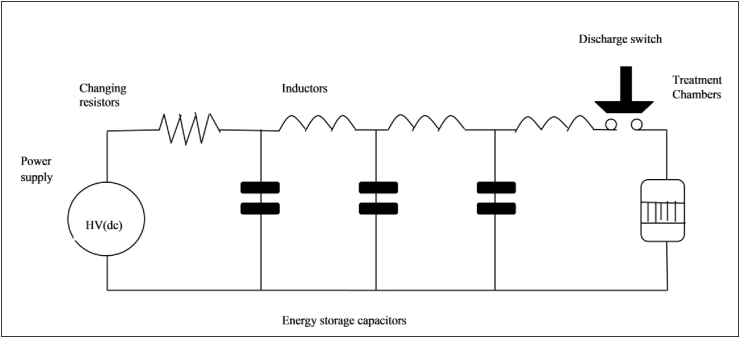

Diverse non-thermal dispensation events were well thought-out by means of the related critical regulation of conservation of food at lower temperatures as evaluated during heat processing technique. This would maintain the nutritional feature of food comprising vitamins, minerals, and necessary flavours whilst employing lower energy as compared to traditional high temperature processing. High pressure processing, oscillating magnetic fields, influential light pulses, irradiation, chemicals and PEF of high strength, as well as the hurdle concepts were established as brilliant non-thermal technique in most recent period [2,14,37]. Eventually the irreversible membrane spoilage destroys the microorganisms. Numerous applications of PEF technology also found for electroporation in cell hybridization in genetic engineering and or biotechnology field same way as other non-thermal processing technologies were proposed for maintenance of food at lower temperatures in general applications during thermal processing [14]. After processing using this technique it preserves the dietary features of food together with vitamins, minerals, and important flavours however utilizing a smaller quantity of energy than thermally treated. The basis for this consideration is because of the PEF capability to destroy the microbes in the food, diminish enzyme activity, and lengthen the shelf-life insignificant alteration in the attributes of the final produce comparing with the unprocessed foods. Based on the strength of field current, electroporation can be classified as reversible or irreversible which means cell membrane exonerate or cell membrane collapse or lysis takes place correspondingly. Nonetheless these consequences can be manipulated on the basis of its function (Fig. 1). PEF set up comprises a high energy pulse producer, one processing compartment together with appropriate fluid controlling structure and required monitor and manipulating processes. Figure [2] illustrates components of basic PEF operation [38]. In a stationary or continuous design food product is positioned in the treatment compartment between a pair of electrodes connecting along with a non-conductive objects to circumvent flow of current throughout the food. High electric field is responsible for lysis of cell membrane permanently in the microbes [18,38]. Therefore, PEF technology has been recommended as the cold pasteurization method for liquid foods specially milk and milk concentrate, yogurt, juices, soups, and liquid eggs [16,30,37,52].

Fig. 1.

Mechanism of microorganisms cell inactivation in PEF.

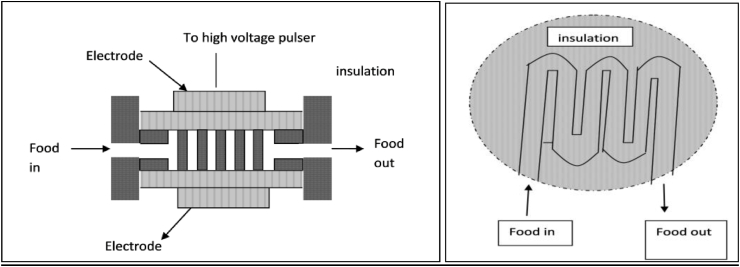

3.1. System components (Figs. 2 and 3)

Fig. 2.

Typical pulser configuration for high intensity pulser electric field.

Fig. 3.

Schematic drawing of a flow-through treatment chamber. Fluid inside the chamber is baffled to avoid dead spots.

A pulsed electric field processing arrangement includes.

-

1)

A processing compartment.

-

2)

A high-energy power supply DC producer

-

3)

A charge electricity temporary resistor,

-

4)

A switch to discharge power through the capacitor in the food

-

5)

A power storage capacitor tank

-

6)

An oscilloscope is useful to watch the pulsate waveform.

The power supply transmits high DC power from 110 V supply line into higher voltage AC line, hence tie up with the high voltage DC line.

To generate an electric field inside the food products, initial energy of power supply is accumulated within a capacitor and subsequently is released to the treatment chamber. Maximum transverse voltage in capacitor is comparable to the power across the producer. The group of electrically simulated capacitors through DC power supplier capable from improved and efficient regular AC current major resources. An electronic switch is to initiate the energy release (instantly in fraction of second) established in the capacitor tank across the food actually in the handling compartment. Beside of that main equipment, some other additional accessories are also essential. For continuous structure, a pump is useful to transmit the food inside the handling compartment. In the cooling section structure might be activated to reduce the ohmic heating outcome and maintain food temperature during processing. Strong power sensors are attached to confirm the electrical energy and current discharge in the compartment [5,19].

Numerous appealing advancements have been considered in the design of operation method of machinery and death mechanism by diverse groups, nonetheless, yet different directions are not completely described. Inactivation kinetics and its consequences of PEF on spores are a number of the major subject for discussion in current studies. In thermal processing technologies normally reduction of the numbers of live spores against processing time is plotted whereas for PEF technology quantity of pulses, have been utilized to illustrate inactivation kinetics is most important ignoring the variations from linear nature of the plot [54].

The elevated strength of PEF dealing out the scheme is an easy electrical structure including an elevated power supply, capacitor tank, switch, and processing compartment. Production of PEF needs a prompt release of electrical power within a short interval. This is capable of pulse forming network (PFN), an electrical path connecting with high power supply of capacity to charge voltages of up to 60 kV, switches, capacitors of range 0.1–10 μF, resistors range of 2Ω–10 MΩ, in the handling compartment [24]. The PEF method adhere to understanding of high voltage numerous pulsar, treatment compartment(s), a cold routed scheme(s), voltage- and current determining plan, control electrical appliance, and a data making procedure (Figure [2] and Figure [3]) [30,38]. A pulse control technique is employed to achieve high voltage from little expediency power voltage, the power system is employed to revitalize a capacitor tank and supervise to discharge energy from the capacitor transversely through the food in the treatment chamber. Processing compartments are believed to clinch the food during PEF treatment and set both the electrodes. Subsequently to handing out the treated item is cooled, when needed, packaged in sterile conditions, and then accumulated sustaining room temperature or cold temperature (4 ± 1) C in the components of foodstuff [45].

3.2. Power supply

Pulses including high power are transmitted to the arrangement by means of a high power pulse generator at necessary strength, nature, and period. The high power supply for the treatment is natural resources of direct current (DC). Another option is a capacitor charge power input with high incidence of AC power inputs that anticipated a necessary charge with high returning rates than the DC power liberation [69].

Fruit juice, milk and other foods of liquid consistency etc. May be treated in a stationary treatment compartment or in a constant dispensation section using a pump. For initial small laboratory-scale study, stationary processing compartment is used, but a continuous processing compartment (s) is gorgeous for the large scale pilot plant or commercial treatment. In order to circumvent unpleasant warm up, chilled water for cooling purpose is re-circulated all the way through the electrodes to cut off the heat generated during electric current transmission throughout the liquid food. Whole processing energy is inadequate as the time period as charging and discharging of capacitor can be done for a specified period [69]. The electricity altercation of the charge resistor also quantity and dimension of capacitors establish the energy requirement to recharge the capacitor, in which a minor capacitor will dictate in lowest interval and energy to be revived than a greater one.

The energy storage capacitor’s capacitance C0 (F) is shown in Eq. (1):

| (1) |

Where τ (s), R (Ω), σ (S/m), d (m) and A (mm2) are pulse duration, resistance, conductivity in food, processing gap between the electrodes, and the total area of the electrode exterior respectively.

The power build up in the capacitor is expressed in Eq. (2);

| (2) |

Where Q, Co and V are the stored energy, the capacitance, and the charge voltage. More complex PFN research proposes square pulsation, bipolar pulse, and instantaneously twisting more or less pulses.

3.3. High-power capacitors

The major tools of elevated power resources are storage capacitors and switches of ON and OFF. Due to comparatively high ohmic power utilization, inductors in contrast to capacitors take part in an insignificant task. The energy stock up in capacitors is used to generate electric or magnetic field. Electric fields are applied to hasten the exciting particles, ultimately thermal, chemical, mechanical, electromagnetic wave, or collapsing property. Magnetic fields support production of enormously high pressures of range 0.1 GPa to many GPa. These things are useful for adjusting the molecules to alter, compact, solder, fragment, section, or demolish resources; and transform the exterior of pieces which are either organic or inorganic in nature [63].

3.4. Switches

The discharge switches also does a crucial job with effectiveness in the PEF arrangement. Switches can be categorised on the basis of how rapid it can complete and how much current as well as voltage it can resist. To extend the service life, appropriate PEF switches comprise parts like ignitrons, spark gaps, trigatrons, thyratrons, and semiconductors. High power switches are made of solid-state semiconductor which has longer life and improved presentation.

In energy storage device, essential constituent is switched the high-power pulse producer. High-power switching performance are relating to intermediary connecting the storage equipment and its control. The hiking set up, nature, and amplitude of the creator efficiency pulse are dependent strongly on the quality of the switches of pulse making devices. Producers with power storage strategy require finishing switch, as generator with inductive storage scheme required ON switches. Two major types of switches at present available: ON switches and ON/OFF switches. ON switches are used for absolute discharge of the capacitor it twisted off after termination of release. ON switches hold voltages in comparatively cheaper cost contrast to ON/OFF switches, nonetheless, disadvantages are the small life and little replication rate [11].

3.5. High voltage pulse generator

Electrical pulses of suitable voltages are generated by the high voltage pulse generators, characterized by means of more or less diverse pulse forming network (PFN). Most important feature of PFN is an electrical circuit including diverse tools. Single/multiple DC power offers a charge resistor, a capacitor pool produced by two or more dissection connecting in analogous, single/multiple switches, and pulse-shaping inductors and resistors. The capacitors are charged with suitable current from DC power provider. A low-energy PEF preparation, control a high voltage pulse maker is developed to take care of infected samples such as grape juice [69]. The arrangement consists of 30 kV D.C. high-voltage pulsation producer, in a rounded processing compartment, tools for siphoning and monitoring. The 110 V A.C. power was elevated in energy through the high power maker, and then adequate D.C. high-voltage provides followed by charge up with 0.12 μF capacitor in the course of a series of 6 MΩ resistors (time constant is 0.72 s). The pulsation creator release 5 V pulses, and the stimulated path suggests transforming 500 V pulses via a Silicon Control Rectifier (SCR). Advancement of elevated voltage pulses is reliant on the discharge of the 0.12 μF capacitor during the thyratron. Processing in a batch can produce small span pulsation (2 ms width, 0.5 Hz frequency) and crest to trough electric field power till 100 kV/cm independently of the low power pulse of (<25 J/pulse) and instantaneous energy turn around and a specific outline is produced.

3.6. Treatment chamber

The major significant as well as complex constituents in the dispensing arrangement are the processing compartments. The fundamental idea of the processing compartment is to maintain the treated product within the compartment throughout pulsing, however the consistency in this practice is extremely reliant on the typical plan of the treatment compartment. As the potency of treated electric fields go beyond the electric field potency of food materials processed inside compartment, crashing of food taken place as a flash. Processing compartments are principally classified as batch or continuous. The batch mode is normally established for treatment of immobile volume of solid or semi-solid foods, two types: parallel plate and coaxial chambers are used. Parallel plate segments have been in general helpful in batch modes while coaxial designs have been operated in nonstop manner and the food material is pumped at a recognized flow rate and pulsations are useful at identified pulse regularity. Coaxial compartments employed in permanent procedure have been established resulting high degradation rates contrasting to batch systems since there are more reliable sharing of the electric field in fluid media [69]. PEF present in diverse chamber designs and PEF investigators studying killing of microorganisms and preservation outcomes have been exceptionally innovative in processing compartment design. Several designs have been introduced during the years for these key constituents, however high energy distributed by the power contribution is useful to the product situated stuck between two electrodes. Fundamental design of processing compartment is maintenance of processed food within the chamber throughout pulsing, even if the reliability of the method is tremendously needy on the perceptive of the processing chamber. If the efficacy of the electric fields exceed the electric field potency of the processed food during treatment in the chamber, breakdown of food ensue due to spark identified as dielectric cracking of food, major consideration to be deliberated in supply in the compartment arrangement. Dielectric degradation of food is usually considered as spoilage of electrode exterior in depths, this bending and amplified pressure, eventually results explosion of processing compartment and growth of gas bubbles. Inherent electrical conflict, homogeneous electric field, and diminution and production of improved field areas of another imperative design criterion for a victorious plan on the basis of power utilization and little temperature processed products.

On the basis of electrical point, PEF processing compartment characterized the load of electricity containing a pair or more electrodes filled with the fluid food to be investigated. The chamber has to be formed in a way that electric field transfer on the fluid is more or less uniform in the complete lively area. Electrode materials also act in a crucial manner. When monopole current waves are utilized, electrode deterioration can turn into significant also the infected food materials to be treated. Technologically reachable electroporation tools with tiny probes made of stainless steel, aluminium, gold-plated, carbon electrodes, and even silver electrodes are applied.

4. Effect of PEF processing

4.1. Effect on microbial cells

4.1.1. The inactivation of microbes by PEF

The purpose of PEF to reduce the microbes populations in different food commodities have been analysed by many researchers. Though, the accurate mechanisms of the inactivation of microbes using PEF has not been totally identified till today. However, common performance of PEF technology developed with instability of microbial membranes by the development of electrical field and electro-mechanical rigidity that transmit to the development of pore in the membrane. Mechanical insecurity of membranes is happened because of crucial membrane potential that is produced in electrical field. Eventually a substantial improvement in the electroporation in the membrane permeability which is known as electro-permeabilization either reversible or irreversible in membrane directional modification eventually cause death of cells. Earlier report elucidated that permeability of membrane is enhanced in substantial way with the rise and synchronization with microbial cells death. Commonly spores are confirmed as more immovable than vegetative cells in PEF technique.

4.1.2. Factors influenced in PEF practice to inhibit microbial growth

The capability of PEF to hamper the microbes reliant on numerous factors such as system factors, techniques of production and types of microbial cells. These factors participated in stimulating role to accomplish the most interesting outcome of PEF handling [59,68].

4.1.3. Process parameters

Numerous factors like electric field potency, length and shape of pulses, number of pulses and the process temperatures of PEF influence the capability of PEF to diminish microbial populace in food. On a universal node, improved concentrations of these parameters are important for microbial death but their accurate relationship with the apparent microbial survival rate is also essential. Thus, accurate amount of all these factors are essential to obtain consistent consequences. Product characteristics of the organization of PEF is inclined by composition of food as a huge variety of commodities are being processed by PEF including dry herbs, milk, liquid eggs and fruit juices, but not suitable for commodities like emulsions. Earlier research explored those physico-chemical characteristics of food such as effect of pH, electrical conductivity, water activity influence the effectiveness of PEF to kill microbes.

Alvarez et al. (2003) stated that superior Salmonella death rate was found in neutral or higher pH foods and diminution in number of L. monocytogenes in high acid food products like citrus juices [2]. Similarly, conductivity of the processing chamber has converse correlation with the death rate of microorganism. It is noticed that extremely electrical conductive foods substantiated poorer inactivation rate of microbes in post PEF action. On the other hand, water activity has direct association with microbe’s death by application of PEF technology as accepted by Min et al. (2003) [33]. Characteristics of death rate of microbes by exploiting PEF technology also dependent on the microbes features together with variety of microbes, genus and strains, typically gram-positive, gram-negative bacteria are regarded as very challenging as compared to yeast cells. Similarly, spores of bacteria and molds are uncontrollable in PEF processing. Furthermore, cell dimensions also influence the microbial death kinetics because of the diversity in the expansion of crucial membrane potential. PEF processing influences Salmonella and E. coli as they are more vulnerable to PEF. Growth parameters such as temperature, medium, and its nutritional composition and pH also manipulate PEF efficacy.

4.2. Effect on food enzymes

The activity of alkaline phosphatase (ALP) is the indicator for milk products whether the milk is pasteurized properly or not or cross-contamination with raw milk. As the occurrence of active ALP designates insufficient pasteurization which concern the risk to public health significantly. ALP is present along with the covering of fat globules membrane and as lipoprotein particles in fresh unprocessed milk and in skim milk respectively. In PEF processing the ALP is deactivated and the process is dependent on the field potency of electric field, milk fat percentage and existence of ALP quantity. Activities of ALP diminished with enhancement of field strength. Reduction of ALP activity from 43% to 59% was established when the enzyme was destroyed in 2% milk after application of 70 pulses or 0.40–0.45 ms at 14.8–18.8 kV/cm [60].

Plasmin and protease two proteolytic enzyme from Pseudomonas fluorescens M3/6 were also deactivated by means of PEFs. A 90% reduction of plasmin activity was confirmed during treatment of 30 and 45 kV/cm, 10–50 pulses for 2 μs duration, and a treatment temperature of 10 °C and 15 °C was maintained. Same time, 80% reduction in activity was attained of protease extracted from P. fluorescens and distributed in Triptych soy broth with 20 pulses for 2 μs was applied at 11–18 kV/cm at 20°C-24 °C temperature. A 60% reduction in activity was monitored in the sterilized skim milk and processed at 98 pulses for 2 μs at 15 kV/cm and 50 °C temperature. On the contrary while for inoculation sterilized casein–Tris buffer was used and PEF treatment was utilized when microbes were active. PEF treatment of 25 kV/cm at 0.6 Hz at 30 °C temperature and protease from P. fluorescens M3/6 was used to increase the proteolytic activity in skim milk. Also found that P. fluorescens M3/6 does not influence the occurrence of calcium in the media restricting the protease. Effect of PEF on food enzyme activity was shown in Table [1].

4.3. Effect of PEF on food constituents

4.3.1. Applications of PEF in food processing

In food processing interest of PEF is rising gradually, because it is considered as a non-thermal option to traditional pasteurization and sterilization process. In the PEF approach, additional chemical preservatives are not needed. Furthermore, the PEF treatment, basically low temperature method, without any major harmful consequences on heat sensitive composite such as vitamins present in foods. The main drawback of PEF process is the primary cost of the setup [1].

4.3.2. Influence of PEF technology on quality parameters of food after treatment

The extraction of anthocyanins from grape juices was done using PEF technology at 50 Hz frequency, 20 μS pulse, and 1.5 kV/cm electric field power. PEF extraction enhanced the release of vitamin C and anthocyanins as well as improved the antioxidant activity of grape juice as compared to untreated samples.

PEF treatment is the most appropriate non-thermal technique to isolate phenols and flavonoids from onions without considerable quality losses. Plant tissues restrain a cytomembrane, which influences the movement of intracellular substances in cells. PEF treatments transformed the functionality (permeability) of cytomembrane by breakdown and enhanced the movement of mass through cells, offering superior yields. Compared to the control samples, the PEF treatment significantly improved the phenolic compounds (102.86 mg GAE/100 g) by 2.2 times and the flavonoid compounds (37.58 mg QE/100 g) by 2.7 times in onions.

PEF treatment (38.4 kV/cm, 272 μs) produced higher extraction yields of polysaccharides (97.7%), protein (48.9%), and polyphenolic compounds (50.9%) in white button mushrooms compared to traditional thermal treatment (95 °C for 1 h). The traditional technique has a prolonged treatment cycle as compared to the PEF system.

The food waste are rich in numerous bioactive components such as phenolic acids, flavonoids (genistein, hesperetin, quercetin, and kaempferol), and carotenoids (lutein and zeaxanthin); hence, it is concerned with the benefits of using PEF to recover valuable compounds that would contribute to the concept of zero waste.

The total polyphenolic content of orange, grapefruit, and lemon were compared in both juice extracts and peels (flavedo/albedo) using PEF (3–10 kV/cm) as a pre-treatment followed by the traditional extraction procedure (50% ethanol for 1 h). The results showed improved flavonoid content and total phenolic contents (2200 mg GAE/100 g) of fruit peels at 10 kV/cm [8,20,22,27,28].

Compared to thermal extraction non-thermal technologies such as pulsed electric field (PEF) support using efficient and easy identification, categorization, and analysis of bioactive components. Other advantages of PEF include cost-efficacy, less time, and solvent utilization with enhanced yields. PEF-assisted extraction leads to a superior yield, exploiting with less solvents and energy consumption, eventually saves a lot of time as compared to traditional extraction techniques. PEF extraction design should be secure and efficient enough to avoid the degradation of phyto-constituents and oils.

Though, research on PEF as a non-thermal technique should not be limited only towards microbial inactivation but also towards the retardation of several spoilage inducing chemical and enzymatic reactions, retention of functional components in food during and after treatment [29,30].

The application of the PEF treatment in wine industry leads to improved wine quality parameters such as phenolic content, total polyphenols index and visual characteristic such as color intensity and clarity. The application of PEF treatment also reduces the maceration time during vinification. The process of compounds releasing, mostly from grape skin, is strictly dependent on grape variety, due to differences in the grape skin layer thickness and the construction of its cell wall. When compared with novel technologies such as high electrostatic pressure or ultrasonics, PEF tends to predominate, particularly in the increasing the antioxidant activity of the extracts. The PEF procedure also has the advantage that it provides lower energy costs and greater product quality than other processing methods [24].

Gocławski et al., 2017 studied the effect of PEF on texture of grape using optical coherence tomography (OCT). Cross-sections revealed the progressive process of expanding zone with strong echo in sub-peel layers what may indicate cell permeabilization or even loosing parenchyma cells integrity. Also grape surface deformations under PEF were quantified. It has been shown that the values of considered textural features in near peel grape tissue were related to the intensity of electric field. Marechal Foch cultivar appeared to be more resistant to PEF than two other grape varieties [24].

4.3.3. Inactivation of microorganisms (log cycle reduction, D)

Fresh and processed apple, peach juice, pea soup, skim milk, beaten eggs, etc. treated with PEFs of 25–45 kV/cm utilizing the compartment which was considered at Washington State University. E. coli inoculum was added in Skim milk and treated to 60 pulses of 2 μs width at 45 kV/cm and 35 °C temperature consequently reduction was by 2D [69]. A diminution of 6D was found when liquid egg was inoculated with E. coli and exposed in a 25.8 kV/cm electric field at 37 °C temperature and 100 pulses of 4 μs [33]. When pea soup was inoculated with E. coli and B. subtilis and treated with PEFs of 25–33 kV/cm (10–30 pulses of 2 μs) reported an imperfect inactivation (1.5D) when the treated temperature of pea soup was less than 53 °C, with microbial inactivation of 4.4 D at treatment temperatures in the range of 53 °C and 55 °C.

4.3.4. Simulated milk ultrafiltrate (SMUF)

E. coli inactivation depends on electric field, pulse number, pH etc. Low-field strength of (20 kV/cm) results an insignificant destruction of microbes independent of temperature and pH (p < 0.05). In the meantime, destruction of E. coli enlarged by means of enhancement of pulses number and amplification of electrical meadow of 40–55 kV/cm range. The death was further important at pH 5.69 than at 6.82 (p < 0.05) but not significant temperature (p < 0.05) range at 10 °C or 15 °C on denaturation.

The influence of pH on sustained survival of microbes is associated with the capability of the microbes to preserve the pH of cytoplasm close to neutral [15]. Membrane permeability enhances to develop cell wall pore during PEF process also the rate of movement of hydrogen ions may also raise because of the osmotic inequality in the cell area. Therefore, a reduction in cytoplasm pH might be recognized because of a large ability of hydrogen ions are available at near neutral pH. The alteration in pH in the cell might maintain chemical changes in DNA or ATP, as considered by Wiggins (1975) [64]. Oxido-reductive reactions planned by Gilliland and Speck (1967) may happen in the cell composition after exposed to PEF chamber [23]. The ionic strength of the liquid food is the indispensable factor in destroying the E. coli. Enhancement of ionic potency cause the electron movement within the fluid, consequently inactivation rate diminishes. The growth of E. coli manipulates the efficiency of PEF practice by means of 2–4 pulses at 36 kV/cm at 7 °C temperature. Cells in the logarithmic phase were significantly susceptible to the electric field presentation distinguished to cells in immobile lag phase [41]. The outcome of log-cycle temperature result the drop of E. coli using logarithmic death pulses and quadrangle wave rhythm of 35 kV/cm. The death rate rises during elevation of temperature. High strength electric fields and sensible temperatures have synergistic effects. Inactivation rate increased as square wave pulses and logarithmically reducing pulses were evaluated. S. aureus when exposed to PEF at 9 and 16 kV/cm and L. delbrueckii and B. subtilis when adjusted to 9, 12, and 16 kV/cm comparable results were obtained.

5. Current applications of PEF in food preservation

Nowadays combination of other food preservation techniques and PEF are applied in food industry to achieve advancement of shelf life of food. Instantaneously blending of preservative, mild thermal treatment, pH modification, use of antimicrobial and nano-material along with PEF generates hurdles for microbes, thus making safe food with extended shelf-life [1].

Buckow et al., 2010 studied PEF in industrial scale manufacturing plant. PEF technology is a new gentle action for pumpable fluid foods protection at low or mild temperatures [13]. The key factors for PEF processing are electric field potency and the temperature, division in the processing compartment are affecting the treatment efficiency and probably the sensory and nutritional feature of fluid foods. A complete three dimensional computational fluid dynamics (CFD) replica of a large-scale PEF structure with co-linear electrodes arrangement was made. The model combines fluid dynamics and electrical field that can be utilized to expect flowing liquid’s prototype, electric field allocation, temperature enhancement, and dwelling period in processing compartment. During continuous treatment for 48 h diverse situations of applied voltageV, pulse replication rate (frequency) f, pulse length τ and flow rate V in four groups, diverse inlet temperatures were replicated for replica liquid foods (NaCl solutions with two diverse electric conductivities), whole milk etc. The replicated PEF energy degenerated into the fluid was in the range of 4–66 kJ/kg and treatment temperatures were in the range 25–80 °C. The calculated temperature data match well (R2 > 0.99) with experimental data in five different places of the process compartments utilizing probes made of fibre optics.

Geveke et al., 2015 studied pasteurization of Strawberry puree using PEF [21]. A cheaper data acquisition technique was made to authenticate the actual amount and outline of the pulses used for the period of PEF treatment. Completely new confirmation method was identified in juxtaposition during growing PEF method for strawberry purée pasteurization. Buffered peptone water (BPW), freshly prepared strawberry purée at pH 2.4 were treated separately in large scale PEF using E.coli (ATCC 35218) as inoculum at 24.0–33.6 kV/cm field strengths, 45.0–57.5 °C temperatures, flow rate 100 L/h. A speed up maturation or storage study was executed on superiority of strawberry beverage prepared from fresh strawberry purée. The survival of E. coliwere reduced by 6.5 log in BPW at 30 kV/cm at 57.5 °C temperature and 7.3 log in strawberry purée at 24 kV/cm at 52.5 °C temperature respectively. Taste and color of strawberry beverage originally made from PEF treated purée was clean and brilliant red, respectively. The color stayed excellent for 3 months or equivalent as fresh during storage but minor flavour drop was observed. The data achievement confine the particulars of all pulses useful at rate of 400 Hz for 1 h of overall more than 1.4 million pulses. In a large-scale PEF unit Strawberry purée was pasteurized. Additionally a data attainment scheme was grown to confirm the method that can assist in acquiring FDA approval of the PEF procedure.

The influence of pretreatment of PEF on the technique of production of industrial french fries and other parameter of potato processing and their influence on process accomplishment and its superiority was observed by Fauster et al., 2018 [17]. PEF resulted cell breakdown and was deliberated by analyzing impedance and smoothening of texture. Tissue Smoothening was observed to generate the cutting performance directed to a smooth cutting exterior and maximum 80% feathering reduction. Thus, starch loss was decreased and an important reduction of fat uptake from 7.5 to 6.8% was found. Breaking loss reduced considerably to 6.0% from 11.0% despite the use of 0.2–1.0 kJ/kg initial energy, because of better resilient features of potato crisps. Results was not noticeable on peeling nature of potato as well as on pasting features of utilizing by-products like puree, even though the lumpy enlarged structure in puree formed made from potato pretreated by PEF. Overall, PEF was shown to distribute comparable and better quality attributes, traditionally accomplished by using thermal preheating at very low power burning up.

Influence of processing factors such as pH, protein percentage on inactivation of Listeria innocua and protection of bioactive nutrients while using PEF technology on preservation of liquid whey protein formulations (Schottroff et al., 2019) [53]. A mild preservation technique for heat sensitive nutrients including protein based formulations during the PEF application was developed. Inactivation of L. innocua was studied using diverse PEF treatment conditions in whey protein isolate (WPI) formulations at 2 and 10% concentration and 4 and 7 two different pH levels, and inlet and outlet temperatures of 20–40 °C and 58 °C respectively resulting inactivation of up to 6.51 CFU of L. innocua without any damage of heat labile nutraceuticals of its original values prior to PEF treatment. The effectiveness of degradation reduced if protein concentrations and pH were raised. The demarcation of thermal and electric field property showed a highest of 1 log10cycle of thermal degradation at the uppermost PEF process strength. The conventional D-value perception was effectively transferred to model the PEF death kinetics [[66], [67], [68], [69], [70]].

Plaza et al., 2011 reported that High Pressure treatment significantly increased total carotenoids and flavanone percentage in extracted juice instantaneously after HP treatment and values were 45.19% and 15.46%, respectively and also 30.89% vitamin A retention with unmodified taste [40]. It was observed that retention of carotenoids and flavanones were higher in high pressure treated juices at refrigerated storage than Low temperature pasteurized or pulse electric field treated juices. Therefore, high pressure and pulse electric field technologies were very efficient or even more than low pasteurization temperature to maintain bioactive complex in orange juice throughout storage at refrigeration temperature.

PEF can be used in food preservation in combination with other hurdles such as the antimicrobials to make more efficient in inactivating microbial flora and extending the shelf-life of refrigerated products than only PEF treatment. PEF hassles the microbial cell to make it more susceptible to antimicrobials like nisin and organic acids. The synergistic effect of antimicrobials have major effect on the inactivation kinetics of PEF due to ease entry of undissociated acids into bacterial cells. Similarly, revelation of microorganisms such as Listeria innocua to PEF may cause sub-lethal injury to the cells and enhance their sensitivity to nisin. Novickij (2020) studied PEF treatment combined with food-compatible antimicrobial agents such as nisin [37]. Combination of nisin-loaded nanoparticles with mild thermal treatment (40 °C, 2 min) and PEF (30 kV/cm; 200 ns – 500 μs protocols, 17.5–87.6 kJ/L) for potentiation of the antimicrobial effects against S. typhimurium and L. innocua. It was confirmed that PEF treatment efficacy non-linearly depend on the energy distributed to the cells, which highlights the dissimilarity in polarization between the two bacteria in sub-micro second range. The mild thermal treatment enhanced the efficacy of nisin nanoparticles and endorsed to inactivate both bacteria in stationary growth phase, while bound the energy density of PEF in 50–90 kJ/L range. The synergistic effect of PEF and nisin-loaded pectin nanoparticles enhanced the sensitivity of gram-negative bacteria to nisin.

6. Current developments and the demand

Recently various groups of researchers have ascertained the prospect to kill a variety of microbes both in buffer and in food products applying diverse PEF design. They investigated the crucial factors as well as major features of food commodities that establish the microbial death kinetics.

Huang and Wang, 2009 studied design of PEF treatment compartment for liquid foods pasteurization process [26]. The modern designs of the PEF processing chambers, reconsidering the diverse designs of stationary and continuous-flow handling compartments, the consequences of essential design parameter, also the presentation of the optimized processing arrangement on the basis of existing compartments.

Sepulveda et al., 2009 studied shelf life of whole milk treatment by pulsed electric fields and generated heat during PEF processing [55]. Use of PEF along with gentle heat treatment was applied to enhance the shelf life of whole milk. When 35 kV/cm pulses for 2.3 μs were useful in PEF treatment for milk at 65 °C for 10 s. Shelf life of the milk was enhanced to more than 24 days which is five times of the traditional process. PEF and thermal processing have synergistic relation. Neither the harsh PEF processing done at lesser temperatures, nor the corresponding gentle heat treatment, as well as higher process times applied might extensively expand the shelf life of milk. Nevertheless, the blending of both PEF and mild temperature expanded milk's shelf life sufficiently. The utilization of heat renewal arrangement enhanced the energy effectiveness of the studied maintenance process producing it extremely reasonable with pasteurization.

Plaza et al., 2011 studied influence of diverse treatment technologies, together with non-thermal technologies, on bioactive components such as carotenoid, flavanone substance of orange juice [40]. Currently extracted orange juice first treated with 400 MPa high pressures at 40 °C for1 min followed by 35 kV/cm PEF for 750 μs treatment and ultimately short pasteurization at 70 °C for 30 s was applied. Immediately after that carotenoids and flavanones were estimated during storage in refrigerator at 4 °C during 40 days of storage. Flavanone amount reduced drastically about 50% at 4 °C on first 20 days storage of processed orange juices, whereas carotenoids reduced about 11% during the last 20 days of storage.

Zhao et al., 2012 studied the current progresses during the accomplishment of PEF on enzymes and proteins [71]. PEF acquires elevated prospective and a brilliant future in food pasteurization of pumpable liquid foods and diminish activity of enzymes. Contrasting with traditional heat pasteurization techniques, foods were lower overstated originally after PEF treatment as they were retained of superior eminence during racking/storage. Currently, this technology is systematic from laboratory and a pilot plant scale levels to industrial scale. In the most recent years, the growing number of studies confirmed that PEF technology is effectual in deactivating main traditional enzymes in foods. PEF technique is also effectively useful to pasteurize protein-based foods. Even though special consideration of PEF originates lower changes to superiority of protein rich foods comparing to heat pasteurization, numerous reports confirmed alteration in constancy and utility of proteins after PEF operation. The modification in composition and utility of enzymes and proteins in PEF processing has received significant interest. The provided information would permit industry and consumers to greater appreciation and estimate the possibility of PEF technology as a substitute or match to conventional technique of food preservation.

Wu et al., 2014 studied colloidal features, protein oxidation and electrophoresis prototype for consideration of alteration of egg white solution in PEF processing [66]. An electric field strength of 25 kV/cm for 400 μs application on protein solution retains the colloidal features, counting soluble protein content, zeta potential, poly dispersity index (PDI) and Z-average size. Nonetheless, when treatment time exceeded 600 μs, with a little peak of big particle size emerges, a dwindling of protein percent (7.84%) and enhancement in Z-average size (36.9%) was found. The main components of the water insoluble parts were combination of lysozyme, ovalbumin and ovo-transferrin.

Wang et al., 2018 reviewed sub lethal properties of PEF on living cells during food processing [47]. PEF treatment, a new technique having electroporation outcome on cells, has an extensive range of practical function especially in food industry. Due to changing vulnerability to PEF, cells reveal one of three probable states after PEF treatment: dead, intact or sub lethally wounded. Authors summarize the significant indications, focusing on the sub lethal consequences of PEF actions of cells throughout food processing. The defensive and metabolic system concerned link with the incident of sub lethal effects are attributed. Additionally, several practical techniques which could be united with PEF to boost the bactericidal consequences are considered in detail. Summing up, PEF technology grasps great assurance as an extensively appropriate, secure technique of pasteurized food.

Andreou et al., 2019 studied the application of PEF to enhance tomato product yield and waste utilization keeping energy expenditure and to minimize the waste effluents [6]. During preserving PEF treatment improved quality attributes of the product. PEF processing enhanced plant cell permeation through electroporation and could be employed in tomato product making to assists peeling, amplify yield of juice and improved utilization of tomato waste. In the first step multiple PEF treatments of different ranges (0.5–1.5 kV/cm, 0–8000 pulses, 15 μs pulse width) were used to whole tomatoes better peeling, dropping to separate peel up to 72.3%. Followed by application of PEF (0.5–2.5) kV/cm, (0–4000) pulses, 15 μs pulse width to chopped tomatoes, with enhancing juice yield to 20.5%. PEF was also functional to the residual part at primary juicing step comprising seeds, peels and a part of tomato kernel, to further enhancement of juice yield up to 90.2%. In third step the effects of PEF on the extraction of high value added constituents from tomato waste were studied. Carotenoid and Lycopene content increased to 56.4% and 14.31 mg/100 g from 9.84 mg/100 g respectively taking tomato waste exposed to PEF treatment at 1.0 kV/cm and 7.5 ms whereas 2 kV/cm, 700 pulses cause enhancement of two times of total phenolic compounds (56.16 mg gallic acid/Kg). Generally, targeted PEF pretreatments included to industrial tomato processing held to decrease energy expenditure and better yield.

Fauster et al., 2018 studied influence of PEF pre-treatment on contraction, rehydration capability and texture of freeze-dried Red bell peppers and Strawberries [17]. To decrease the adverse effect on the commodities physical properties, PEF treatment at stable electric field strength of E = 1.0 kV/cm and correct energy input was freckled between 0.3 and 6.0 kJ/kg for 2.0–28.6 ms. In addition, the effect of diverse pre-freezing temperatures (−4 and −40 °C) on end product was illustrated. PEF treatment significantly dwindles the contraction incident for both bell peppers and strawberries were noticed in comparison to untreated samples with 30% and 50% lesser volume decreases respectively but rehydration capacity of PEF pre-treated freeze-dried samples increased up to 50% with a considerable firmness and mechanical properties diminishes up to 60%. PEF can be an efficient pre-treatment process with lower energy requirement and improved quality attributes of freeze-dried fruits and vegetables.

Bai et al., 2021 studied PEF pre-treatment altering flavour texture, digestion and structure of rice [8]. Influence of PEF pre-treatment on hydrolysis, lamellar structure, texture, thermal properties, sensory properties were considered. PEF pre-treatment, confirmed encouraging influences on degree of starch hydrolysis and glycemic index when cooked rice was treated. They reported the influence of PEF on textural properties like hardness, cohesiveness, springiness and chewiness of cooked rice significantly (P < 0.05). PEF decreased the reliability of cell structure, changed the relative crystallinity degree, gelatinization enthalpy, semi-crystalline layered structure of rice lightly, devoid of apparently altering the diffractive prototype of rice grains. PEF pre-treatments result reduction of ketones and phenols content and improvement of aldehydes and acids in cooked rice.

7. Demerits of PEF

Morren et al., 2003 studied the electrode corrosion during PEF processing depends on the flow of current and the frequency [35]. It was shown that corrosion can be limited by applying short enough pulses. Experiments are described that below 100 Hz the current is decreasing, which implicates higher cell impedance. The used electrodes are the only metal parts in the experimental system. Both electrodes are made of Stainless Steel 316, which contains Carbon (F0.08%), Silicon (F1%), Manganese (F2%), Phosphorous (F0.045%), Sulfur (F0.03%), Chromium (16–18%), Molybdenum (2–3%), Nickel (10–14%) and Iron (38–45%). The samples taken for analysis for heavy metal like Chromium (Cr), Iron (Fe), Manganese (Mn) and Nickel (Ni). If electrodes undergo corrosion then PEF treated food will be contaminated [35].

According to the basic theory of corrosion of the electrodes it can be minimized by using small pulses. Cumulative build-up of charge must be removed. This can be done either by avoiding the charge after each pulse or by using bipolar pulses. Experiments have been done to scrutinize the incidence of electrode corrosion as a function of the pulse amplitude and pulse length. Theory can be used to establish the minimum pulse width that is necessary to prevent electrode corrosion in PEF treatment structures.

8. Conclusion and perspectives

The aim of food preservation technique is to inactivate microorganisms once they are detected before foods spoilage. PEF is a very important non-thermal preservation technique to substitute traditional thermal treatment. When treated with high electrical field pulsation, pores develop or enlarge in cell membranes. The PEF assembly consists of a high power pulsation producer, a processing compartment, and measuring equipments for current and voltages. Treatment chamber contains two electrodes set parallels by insulation material that produce an attachment which contains the food for treatment. The high strength of PEF leads to production of short time pulses for micro to milli seconds amid a pair of parallel plate electrodes surrounded by dielectric material intensities in the range of 10–80 kV/cm, useful to a food product in a chamber at room temperature. The purpose of PEF is inactivation of microorganisms in the food, diminishes enzymatic activity, and expands the shelf-life with irrelevant alteration in the quality of the final food in contrast to the novel one. Current chapter focused on basic principle of PEF, various equipment configurations, mechanisms of pulsed electric field systems, including the electrical bases, various types of electric circuits, processing chambers and application of PEF in food processing and its future aspects.

Author contribution statement

All authors listed have significantly contributed to the development and the writing of this article. Data availability statement: Data included in article/supp. Material/referenced in article. Declaration of interest’s statement: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

Author is thankful to Dr. S.S.BUICET, Panjab University for providing all facility to carry out the review.

References

- 1.Altunakar B., Gurram S.R., Barbosa-Cánovas G.V. Woodhead Publishing Ltd; 2007. Applications of Pulsed Electric Fields for Food Preservation in Food Preservation by Pulsed Electric Fields: from Research to Application; pp. 266–293. [Google Scholar]

- 2.Alvarez P.R., Condon S., Raso J. The influence of process parameters for the inactivation of Listeria monocytogenes by pulsed electric fields. Int. J. Food Microbiol. 2003;87:87–95. doi: 10.1016/s0168-1605(03)00056-4. [DOI] [PubMed] [Google Scholar]

- 3.Álvarez I., Heinz V. In: Hurdle Technology and the Preservation of Food by Pulsed Electric Fields. Lelieveld H.L.M., Notermans S., Haan S. W. H. de, editors. Woodhead Publishing Ltd; Cambridge: 2007. pp. 165–177. [Google Scholar]

- 4.Alvarez R., Sala F., Condon S. Inactivation of Yersinia enterocolitica by pulsed electric fields. Food Microbiol. 2003;20:691–700. [Google Scholar]

- 5.Amiali M., Ngadi M.O., Raghavan G.S.V., Smith J.P. Inactivation of Escherichia coli O157:H7 and Salmonella enteritidis in liquid egg white using pulsed electric field. J. Food Sci. 2006;71:88–94. [Google Scholar]

- 6.Andreou V., Dimopoulos G., Dermesonlouoglou E., Taoukis P. Application of pulsed electric fields to improve product yield and waste valorization in industrial tomato processing. J. Food Eng. 2020;270 doi: 10.1016/j.jfoodeng.2019.109778. [DOI] [Google Scholar]

- 7.Army E.P.R. 1997. Pulsed Electric Field Workshop//: Minutes, Industrial and Agricultural Technologies and Services, Palo Alto, CA. [Google Scholar]

- 8.Axelrod R.D., Baumgartner J., Alexander Mathys M.A., Bai G., Zhang L., Qian J., Jiang W., Wu M., Rao S., Li Q., Zhang C., Wu C. Pulsed electric field pretreatment modifying digestion, texture, structure and flavor of rice. LWT--Food Sci. Technol. 2021;138 [Google Scholar]

- 9.Barsotti L., Merle P.P., Cheftel J. Food processing by pulsed electric fields. Physical aspects. Food Res. Int. 1999;15(2):163–180. [Google Scholar]

- 10.Bayindrili A. 2010. Chapter-1 2 Enzymes in Fruit and Vegetable Processing: Future Trends in Enzyme Discovery, Design, Production, and Application. 341, CRC press. [Google Scholar]

- 11.Bluhm H. Springer; Berlin: 2006. Pulsed Power Systems: Principles and Applications. [Google Scholar]

- 12.Bouzrara H., Vorobiev E. Non-thermal pressing and washing of fresh sugarbeet cossettes combined with a pulsed electrical field. Material Science. Zuckerindustrie. 2001;126(6):463–466. [Google Scholar]

- 13.Buckow R., Schroeder S., Berres P., Baumann P., Knoerzer K. Simulation and evaluation of pilot-scale pulsed electric field (PEF) processing. J. Food Eng. 2010;101(1):67–77. [Google Scholar]

- 14.Chang D.C., Saunders J.A., Chassy B.M., Sowers A.E. In: Guide to Electroporation and Electrofusion. Chang D.C., Chassy B.M., Saunders J.A., Sowers A.E., editors. Academic Press, Inc.; San Diego, CA: 1992. Overview of electroporation and electrofusion; pp. 1–6. [Google Scholar]

- 15.Corlett D.A., Brown M.H. Factors Affecting the Life and Death of Microorganisms. Academic Press; New York: 1980. pH and acidity. [Google Scholar]

- 16.Daniel A., Jacobo-Velázquez D.A., Santana-Gálvez J., Cisneros-Zevallos L. Designing next-generation functional food and beverages: combining nonthermal processing technologies and postharvest abiotic stresses. Food Eng. Rev. 2021;13:592–600. [Google Scholar]

- 17.Fauster T., Schlossnikl F., Rath D., Ostermeier R., Teufel F., Toepfl S., Jaeger H. Impact of pulsed electric field (PEF) pretreatment on process performance of industrial French fries production. J. Food Eng. 2000;235:16–22. [Google Scholar]

- 18.Fernandez-Díaz M.D., Barsotti L., Dumacy E., Chefter J.C. Effects of pulsed electric fields on ovalbumin solutions and dialyzed egg white. J. Agric. Food Chem. 2018;48:2332–2339. doi: 10.1021/jf9908796. [DOI] [PubMed] [Google Scholar]

- 19.Floury J., Grosset N., Leconte N., Pasco M., Madec M., Jeantet R. Continuous raw skim milk processing by pulsed electric field at non-lethal temperature: effect on microbial inactivation and functional properties. Dairy Sci. Technol. 2005;86:43–57. [Google Scholar]

- 20.Gerlach D., Alleborn N., Baars A., Delgado A., Moritz J., Knorr D. Numerical simulations of pulsed electric fields for food preservation: a review. Innovat. Food Sci. Emerg. Technol. 2008;9(4):408–417. [Google Scholar]

- 21.Geveke D.J., Aubuchon I., Zhang H.Q., Boyd G., Sites J.E., Bigley A.B.W. Validation of a pulsed electric field process to pasteurize strawberry purée. J. Food Eng. 2015;166:384–389. [Google Scholar]

- 22.Ghazanfari N., Yazdi F.T., Mohammadi M. Using pulsed electric field pre-treatment to optimize coriander seeds essential oil extraction and evaluate antimicrobial properties, antioxidant activity, and essential oil compositions. Lebensm. Wiss. Technol. 2023;182(1) doi: 10.1016/j.lwt.2023.114852. [DOI] [Google Scholar]

- 23.Gilliland S.E., Speck M.L. Mechanism of the bactericidal action produced by electro hydraulic shock. Appl. Microbiol. 1967;15:1038. doi: 10.1128/am.15.5.1038-1044.1967. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Gocławski J., Sekulska-Nalewajko J., Korzeniewska E., Piekarska A. The use of optical coherence tomography for the evaluation of textural changes of grapes exposed to pulsed electric field. Comp. Elect. Agric. 2017;142:29–40. doi: 10.1016/j.compag.2017.08.008. [DOI] [Google Scholar]

- 25.Gongora-Nieto M.M., Sepulveda D., Pedrow P., Barbosa-Cánovas G., Swanson B. Food processing by pulsed electric fields: treatment delivery, inactivation level, and regulatory aspects. Lebensm. Wiss. Technol. 2002;35(5):375–388. [Google Scholar]

- 26.Huang K., Wang J. Designs of pulsed electric fields treatment chambers for liquid foods pasteurization process: a review. J. Food Eng. 2009;95(2):227–239. [Google Scholar]

- 27.Jemai A.B., Vorobiev E. Pulsed electric field assisted pressing of sugar beet slices: towards a novel process of cold juice extraction. Biosyst. Eng. 2007;93(1):57–68. [Google Scholar]

- 28.Kamboj A., Chopra R., Prassana K.G.V. Effect of pulsed electric field parameters on the alkaline extraction of valuable compounds from perilla seed meal and optimization by central composite design approach. Appl. Food Res. 2022 doi: 10.1016/j.afres.2022.100240. [DOI] [Google Scholar]

- 29.Kim S., Jeong S., Lee D. Accelerated brining kinetics and NaCl distribution of Chinese cabbage (Brassica rapa ssp. pekinensis) using pulsed electric field. Lebensm. Wiss. Technol. 2023;179(1) doi: 10.1016/j.lwt.2023.114634. [DOI] [Google Scholar]

- 30.Li Y., Wang J., Han Z. The microstructure and thermal properties of pulsed electric field pretreated oxidized starch. Int. J. Biol. Macromol. 2023;235 doi: 10.1016/j.ijbiomac.2023.123721. [DOI] [PubMed] [Google Scholar]

- 31.Loeffler M.J. Generation and application of high intensity pulsed electric fields. Pulsed Electric Fields Tech. Food Indust. Fundament. Applicat. 2006;27:72. isbn-13, 978-970387-31053-4. [Google Scholar]

- 32.Loey A., Verachtert B., Hendrickx M. Effects of high electric field pulses on enzymes. Trends Food Sci. Technol. 2001;12(3–4):94–102. [Google Scholar]

- 33.Martin O., Vega-Mercado H., Qin B.L., Chang F.J., Barbosa-Cánovas G.V., Swanson B.G. Inactivation of E. coli suspended in liquid eggs using pulsed electric fields. J. Food Process. Preserv. 1997;21:193. [Google Scholar]

- 34.Min S., Jin Z.T., Zhang Q.H. Commercial scale pulsed electric field processing of tomato juice. J. Agric. Food Chem. 2003;51(11):3338–3344. doi: 10.1021/jf0260444. [DOI] [PubMed] [Google Scholar]

- 35.Morren J., Roodenburg B.S., de Haa W.H. Electrochemical reactions and electrode corrosion in pulsed electric field (PEF) treatment chambers, Innov. Food Sci. Emer. Technol. 2003;4:285–295. [Google Scholar]

- 36.Niu D., Zeng X.A., Ren E.F., Xu F.Y., Li J., Wang M.S., Wang R. Review of the application of pulsed electric fields (PEF) technology for food processing in China. Food Res. Int. 2020;137 doi: 10.1016/j.foodres.2020.109715. [DOI] [PubMed] [Google Scholar]

- 37.Novickija V., Stanevičienėb R., Staigvilaa G., Gruškienėc R., Sereikaitėc J., Girkontaitėd I., Novickija J., Servienėb E. Effects of pulsed electric fields and mild thermal treatment on antimicrobial efficacy of nisin-loaded pectin nano-particles for food preservation. LWT--Food Sci. Technol. 2020;120 [Google Scholar]

- 38.Ortega-Rivas E., Zárate-Rodríguez E., Barbosa-Cánovas G.V. Apple juice pasteurization using ultrafiltration and pulsed electric fields. Food Bioprod. Process. 1998;76(4):193–198. [Google Scholar]

- 39.Peña M.M., Rábago-Panduro L.M., Soliva-Fortuny R., Martín-Belloso O., Welti-Chanes J. Pulsed electric fields technology for healthy food products. Food Eng. Rev. 2021;13(15):509–523. [Google Scholar]

- 40.Plaza L., Sánchez-Moreno C., Ancos B.D., Elez-Martínez P., Martín-Belloso O., PilarCano M. Carotenoids and flavanone content during refrigerated storage of orange juice processed by high-pressure, pulsed electric fields and low pasteurization. LWT--Food Sci. Technol. 2011;44(4):834–839. [Google Scholar]

- 41.Pothakamury U.R., Monsalve-González A., Barbosa-Cánovas G.V., Swanson B.G. Inactivation of E. coli and S. aureus in model foods by pulsed electric field technology. Food Res. Int. 1995;28(2):167. [Google Scholar]

- 42.Puc M., Čorovič S., Flisar K., Petkovsek M., Nastran J., Miklavčič D. Techniques of signal generation required for electro-penneabilization. Survey of electro-penneabilization devices. Bio-electrochem. 2004;64:113–124. doi: 10.1016/j.bioelechem.2004.04.001. [DOI] [PubMed] [Google Scholar]

- 43.Punthi F., Yudhistira B., Gavahian M., Chang C.K., Cheng K.C., Hou C.Y., Hsieh C.W. Pulsed electric field‐assisted drying: a review of its underlying mechanisms, applications, and role in fresh produce plant‐based food preservation. Compr. Rev. Food Sci. Food Saf. 2022;21(6):5109–5130. doi: 10.1111/1541-4337.13052. [DOI] [PubMed] [Google Scholar]

- 44.Qin B.L., Barbosa-Cánovas G.V., Swanson B., Pedrow P.D., Olsen R.G. Inactivating microorganisms using a pulsed electric field continuous treatments system. IEEE Trans. Ind. Appl. 1998;34:43–50. [Google Scholar]

- 45.Qin B.L., Chang F., Barbosa-Cfinovas G.V., Swanson B.G. Nonthermal inactivation of Saccharomyces cerevisiae in apple juice using pulsed electric fields. Lebensm.-Wiss. Technol. 1995;28:564–568. [Google Scholar]

- 46.Ramanan M.R., Barba F.J., Lorenzo M.J., López F., Munekata O.E.S., Roohinejad S., Sant'Ana A.S., Tiwari B.K. Recent advances in the application of pulsed light processing for improving food safety and increasing shelf life. Trends Food Sci. Technol. 2019;88:67–79. [Google Scholar]

- 47.Ranjha M.M.A.N., Kanwal R., Shafique B., Arshad R.N., Irfan S., Kieliszek M., Kowalczewski P.Ł., Irfan M., Khalid M.Z., Roobab U., et al. A critical review on pulsed electric field: a novel technology for the extraction of phytoconstituents. Molecules. 2021;26:4893. doi: 10.3390/molecules26164893. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Raso J., Heinz V., editors. Pulse Electric Fields Technology for the Industry. Fundamentals and Application. second ed. 2006. p. 476. [Google Scholar]

- 49.Ricós-Muñoz N., Soler A.R., Castagnini J.M., Moral R., Barba F.J., Pina-Pérez M.C. Improvement of the probiotic growth-stimulating capacity of microalgae extracts by pulsed electric fields treatment. Innovat. Food Sci. Emerging Technol. 2023;83 [Google Scholar]

- 50.Rivero-Ramos P., Unthank M.G., Tinoco M.B. Synergistic depolymerisation of alginate and chitosan by high hydrostatic pressure (HHP) and pulsed electric fields (PEF) treatment in the presence of H2O2. Carbohydr. Polym. 2023 doi: 10.1016/j.carbpol.2023.120999. In press. [DOI] [PubMed] [Google Scholar]

- 51.Salgado-Ramos M., Martí-Quijal F.J., Barba F.J. A preliminary multistep combination of pulsed electric fields and supercritical fluid extraction to recover bioactive glycosylated and lipidic compounds from exhausted grape marc. Lebensm. Wiss. Technol. 2023 doi: 10.1016/j.carbpol.2023.120999. [DOI] [Google Scholar]

- 52.Schilling S., Schmid S., Jager H., Ludwig M., Dietrich H., Toepfl S., Knorr D., Neidhart S., Schieber A., Carle R. Comparative study of pulsed electric field and thermal processing of apple juice with particular consideration of juice quality and enzyme deactivation. J. Agric. Food Chem. 2008;56:4545–4554. doi: 10.1021/jf0732713. [DOI] [PubMed] [Google Scholar]

- 53.Schottroff F., Gratz M., Jaeger H. Pulsed electric field preservation of liquid whey protein formulations – influence of process parameters, pH, and protein content on the inactivation of Listeria innocua and the retention of bioactive ingredients. J. Food Eng. 2019;243:142–152. [Google Scholar]

- 54.Sepulveda D.R., Barbosa-Cánovas G.V. Novel Food Process Technologies. G. V. Barbosa-Cánovas, M. S. Tapia M. P. Cano Edited. CRC Press; Boca Raton, FL: 2005. Present status and the future of PEF technology; pp. 1–45. [Google Scholar]

- 55.Sepulveda D.R., Góngora-Nieto M.M., Guerrero J.A., Barbosa-Cánovas G.V. Shelf life of whole milk processed by pulsed electric fields in combination with PEF-generated heat. LWT--Food Sci. Technol. 2009;42(3):735–739. [Google Scholar]

- 56.Sitzmann W., Vorobiev E., Lebovka N. Applications of electricity and specifically pulsed electric fields in food processing: historical backgrounds. Innovat. Food Sci. Emerg. Technol. 2016;37:302–311. [Google Scholar]

- 57.Soltanzadeh M., Peighambardoust S.H., Gullon P., Hesari J., Gullón B., Alirezalu K., Lorenzo J. Quality aspects and safety of pulsed electric field (PEF) processing on dairy products: a comprehensive review. Food Rev. Int. 2022;38(1):96–117. [Google Scholar]

- 58.Steinbruch E., Wise J., Golberg A. Enzymatic cell wall degradation combined with pulsed electric fields increases yields of water-soluble-protein extraction from the green marine macroalga Ulva sp. Innovat. Food Sci. Emerg. Technol. 2023;84 doi: 10.1016/j.ifset.2022.103231. [DOI] [Google Scholar]

- 59.Toepfla S., Heinz V., Knorr D. High intensity pulsed electric fields applied for food preservation. Chem. Eng. Process. 2007;46:537–546. [Google Scholar]

- 60.Tsong T.Y. Review on electroporation of cell membranes and some related phenomena. Biochem. Bioeng. 1990;24:271. [Google Scholar]

- 61.Tsong T.Y. Electroporation of cell membranes. Biophys. J. 1991;60:297. doi: 10.1016/S0006-3495(91)82054-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Wang M., Wang L., Bekhit A., Yang A., Hou Z., Wang Y., Dai Q., Zeng X. A review of sublethal effects of pulsed electric field on cells in food processing. J. Food Eng. 2018;223:32–41. [Google Scholar]

- 63.Weise H.G.G., Loeffler M.J. Proceedings of the International Conference on Pulsed Power Applications. Gelsenkirchen; Germany: 2001. Overview on pulsed power applications. A.0I/I-A.01/8. [Google Scholar]

- 64.Wiggins P.M. Cellular functions of a cell in a metastable equilibrium state. J. Theor. Biol. 1975;52:99. doi: 10.1016/0022-5193(75)90042-9. [DOI] [PubMed] [Google Scholar]

- 65.Wouters P.C., Alvarez I., Raso J. Critical factors determining inactivation kinetics by pulsed electric field food processing. Trends Food Sci. Technol. 2001;12(3–4):112–121. [Google Scholar]

- 66.Wu L., Zhao W., Yang R., Chen X. Effects of pulsed electric fields processing on stability of egg white proteins. J. Food Eng. 2014;139:13–18. [Google Scholar]

- 67.Yildiz S., Pokhrel P.R., Unluturk S., Barbosa-Cánovas G.V. Changes in quality characteristics of strawberry juice after equivalent high pressure, ultrasound, and pulsed electric fields processes. Food Eng. Rev. 2021;13:601–612. doi: 10.1016/j.foodres.2020.110040. [DOI] [PubMed] [Google Scholar]

- 68.Yousef A.E., Zhang H.Q. Advances in Microbial Food Safety; V. Juneja, et al.; ACS Symposium Series; American Chemical Society: Washington, DC. 2006. Microbiological and safety aspects of pulsed electric field technology. [Google Scholar]

- 69.Zhang Q.H., Qin B.L., Barbosa-Cánovas G.V., Swanson B.G., Pedrow P.D. Batch mode for treatment using pulsed electric fields. US Patent. 1996;5(549) [Google Scholar]