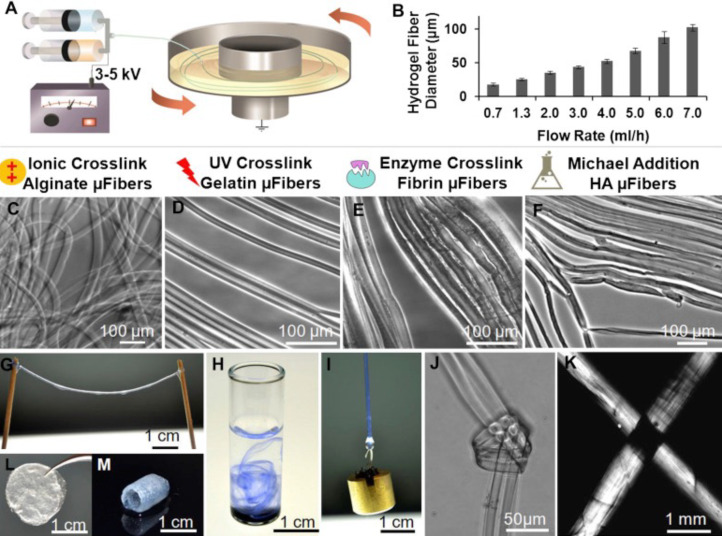

Figure 2.

Preparation of hydrogel nanofiber. A: Illustration of the electrostretching setup; B: Effect of alginate solution feeding rate on the diameter of hydrogel microfibres; C-F: Various crosslinking mechanisms have been employed to crosslink alginate, gelatin, fibrin and hyaluronic acid hydrogel microfibers; G: Hydrogel microfibres of any desired length can be prepared; H: When dispersed in water, alginate hydrogel fibres formed a loose network of hydrogel fibres; I: A 10-g metal pillar was lifted with an alginate hydrogel microfibre bundle; J and K: A micro-knot was made with two alginate hydrogel microfibres; L and M: Beyond microfibre bundles, these hydrogel microfibres can also be fabricated into other forms like fibrous films (L) and self-supporting hydrogel tubes (M). Reproduced with permission[32]. Citation: Zhang S, Liu X, Barreto-Ortiz SF, Yu Y, Ginn BP, DeSantis NA, Hutton DL, Grayson WL, Cui FZ, Korgel BA, Gerecht S, Mao HQ. Creating polymer hydrogel microfibres with internal alignment via electrical and mechanical stretching. Biomaterials 2014; 35: 3243-3251. Copyright© The Authors 2013, Published by Elsevier Ltd.