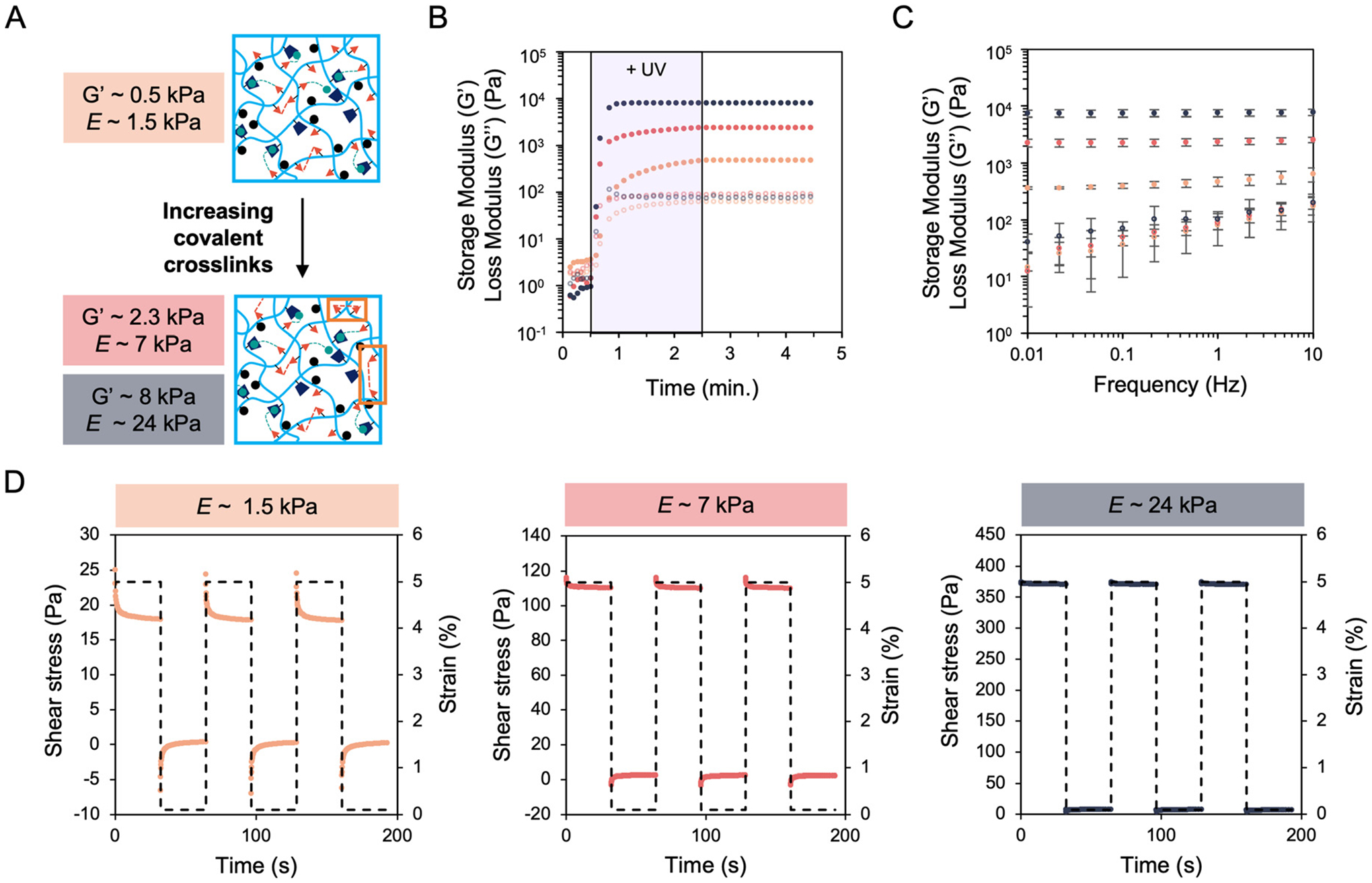

Fig. 2.

Mechanical characterization of increasingly stiff and elastic hydrogels. (A) Schematic of crosslinking chemistry illustrating formation of stiffer hydrogels through the incorporation of increased covalent dithiol crosslinks. (B) Rheology showed a loss modulus (G”, open circles) within an order of magnitude of the storage modulus (G’, closed circles) for the softest, G’ ~ 0.5 kPa, (orange) viscoelastic hydrogel. Hydrogels with G’ ~ 2.5 kPa (red) and ~8 kPa (blue) were made with the same loss moduli of the softest hydrogel to form stiffer and more elastic hydrogels mimicking progressively more fibrotic lung tissue. (C) Frequency sweeps of the three hydrogel groups illustrated increased loss moduli with increasing frequency. Error bars represent the S.D. of the average of three tests. (D) Stress relaxation testing for the three hydrogel groups showed greater relaxation for the softest hydrogel group while the stiffer groups displayed less relaxation. At least three tests were performed for each experimental group.