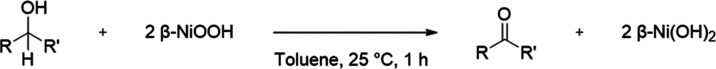

Table 2. Control Experiments and Broader Applicability of the System in the Alcohol Oxidationa.

| entry | variation from conditions | substrate conversion (%) | yield (%) |

|---|---|---|---|

| 1a | none | >95 | >95 |

| 2a | γ-NiOOH as oxidant | >95 | 85 |

| 3a | β-Ni(OH)2 as oxidant | <5 | <5 |

| 4a | no oxidant | <5 | <5 |

| 5a | benzaldehyde as substrate | <5 | <5c |

| 6b,f | cinnamyl alcohol as substrate | 79 (1 h), >95 (16 h) | 79 (1 h), >95 (16 h)d |

| 7b,f | 1-phenylethanol as substrate | 59 (1 h), >95 (16 h) | 59 (1h), >95 (16 h)e |

Conversions and yields are based on (a) GC-analysis using chlorobenzene in acetonitrile as external standard or (b) 1H-NMR integration using 1,3,5-trimethoxybenzene as internal standard. Superscripts refer to (c) benzoic acid-, (d) cinnamaldehyde- and (e) acetophenone yield. (f) Product formation was also confirmed with GC-MS.