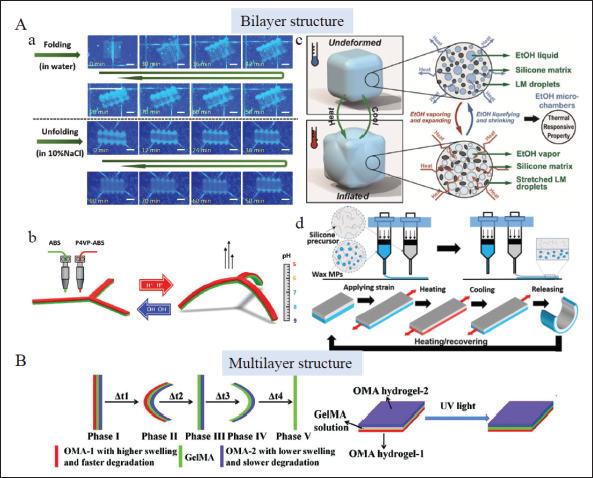

Figure 3.

Bi-/multi-layer structure design in 4D printing. (A) Bilayer structural design, a) Reversible transformation of bilayer hydrogel induced by water absorption and dehydration behavior of driving layer in different osmotic pressure solutions[76]. Copyright 2020, Elsevier. b) A pH-sensitive claw deforming caused by anisotropic volume change in an aqueous solution under different pH conditions[77]. Copyright 2022, Elsevier. c) Volume change of the driving layer caused by liquid-vapor-phase change of ethanol micro chambers when heated or cooled81]. Copyright 2020, American Chemical Society. d) 4D deforming procedures powered by a pre-stored stress field in the driving layer consisting of wax microparticles[84]. Copyright 2021, American Chemical Society. (B) Multi-layer structural design, a trilayer structure consisting of two outer oxidized methacrylated alginate (OMA) layers with different swelling and degradation capacities and a GelMA layer underwent five phases of deformation due to anisotropic swelling of the three layers and the degradation of the fast-degradation layer[89]. Copyright 2021, Wiley-VCH. LM: Liquid metal; MP: Microparticle; OMA: Oxidized and methacrylate alginate.