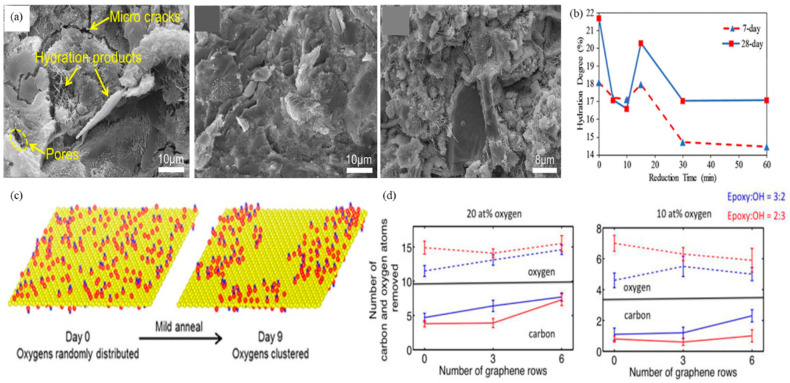

Figure 6.

(a) (left) After 28 days of curing, the microstructure of cement paste was analyzed; (middle) The control sample showed many pores and microcracks, while the addition of GO resulted in few isolated crystals due to more hydration products; (right) Addition of rGO led to a denser microstructure with fewer pores [8]; Adapted from Ref. [8]. Copyright 2020 Elsevier. (b) Moderately reduced rGO was found to have the highest cement hydration, while highly reduced rGO led to a decline in cement hydration, indicating the need to balance the reduction degree of GO with the defects in the graphene structure [9]; Adapted from Ref. [9]. Copyright 2017 American Chemical Society. (c) A mild thermal annealing process enhances GO properties by promoting the phase transition of graphitic domains. Oxygen diffusion on the GO surface leads to hybridization of significant oxide and graphite regions, resulting in a mixture of sp2 and sp3 domains. A diagram featuring carbon (yellow), oxygen (red), and hydrogen (blue) atoms is provided [101]; Adapted from Ref. [101]. Copyright 2017 American Chemical Society. (d) GO contains epoxy and hydroxyl groups attached to the edge, which can be removed in high- and low-oxygen environments. Epoxy-rich GO domains lose more carbon and oxygen atoms as the oxygen cluster increases [98]. Adapted from Ref. [98]. Copyright 2016 Elsevier.