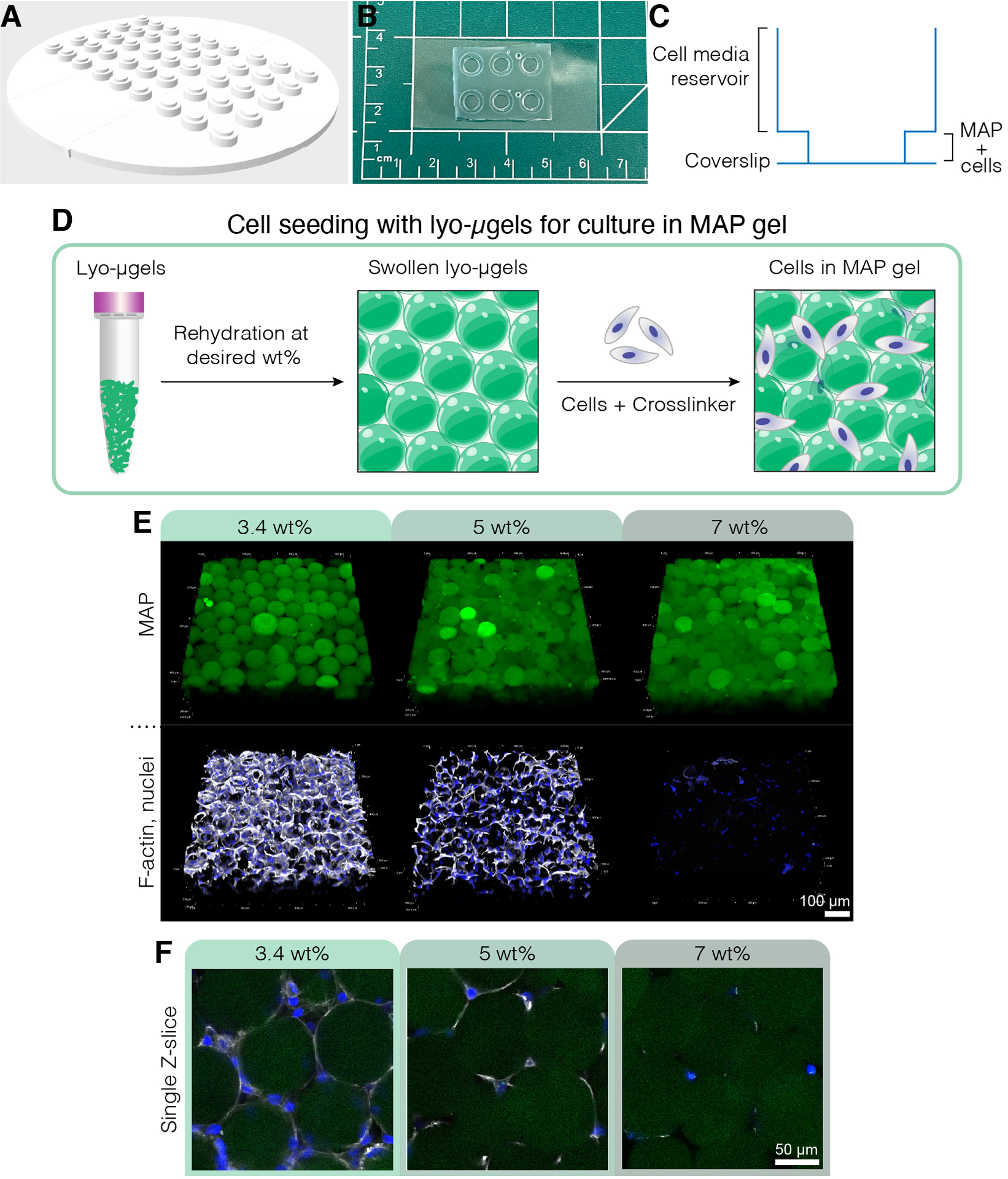

Figure 5.

A) The mold for creating cell culture wells can be 3D printed and cast with PDMS. The entire mold is 95 mm in diameter, the large wells are 6 mm in diameter, and the small inner wells are 4 mm in diameter. B) Once cast with PDMS, the cell culture devices are plasma bonded to coverslips for improved microscopy capabilities. C) The cross section of a cell culture well depicts the reservoir for cell media (~50 μL) and a smaller reservoir for seeding MAP scaffold with cells (~10 μL). D) The process of seeding cells in MAP scaffolds first relies on the rehydration of lyo-μgels at the user’s desired wt %, followed by mixing with cells and the crosslinker for interlinking the μgels. E) Cells can be encapsulated in MAP scaffolds (green) with varied wt % MAP. Representative images are from day 5 of D1 cell culture in MAP scaffolds (scale bar = 100 μm). F) Single Z-slices show differences in cell growth in scaffolds comprised of different wt % MAP (scale bar = 50 μm). Reprinted from Acta Biomaterialia, Volume 150, Alexa R. Anderson, Ethan Nicklow, Tatiana Segura, Particle fraction is a bioactive cue in granular scaffolds, Copyright 2022, with permission from Elsevier.12