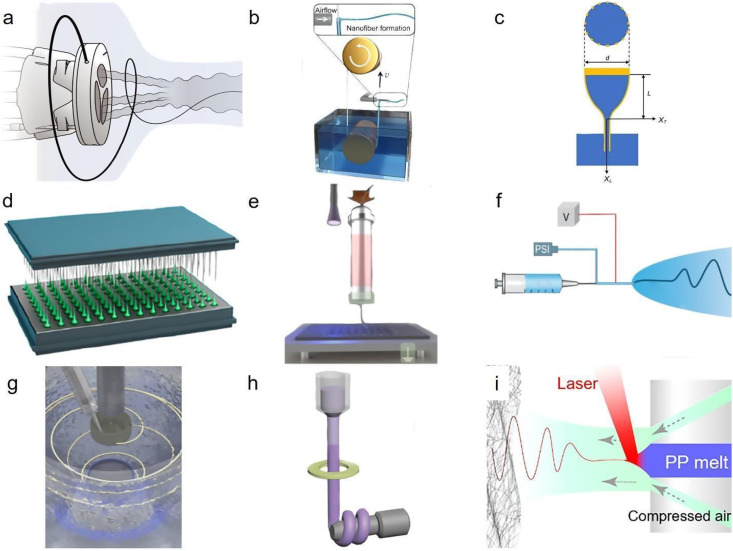

FIG. 4.

Emerging fabrication methods to produce functional fibers. (a) Usage of air in controlled alignment of fibers produced by rotary jet spinning. Reproduced with permission from Chang et al., Science 377, 180 (2022). Copyright 2022 American Association for the Advancement of Science.85 (b) Spinning solution on a rolling thread through jetting produced by shear stresses of a high-speed gas flow. Reproduced with permission from Li et al., Sci. Adv. 8, eabn3690 (2022). Copyright 2022 Authors, licensed under a Creative Commons Attribution (CC BY) license.87 (c) Schematics of elastocapillary production of fibrous structures. Reproduced with permission from Guan et al., Sci. Adv. 5, eaav2842 (2019). Copyright 2019 American Association for the Advancement of Science.88 (d) Schematics of capillary-control fiber spinning. Reproduced with permission from Ni et al., Nano Lett. 22, 9396 (2022). Copyright 2022 American Chemical Society.89 (e) Schematic illustration of melt electrowriting. Reproduced with permission from Javadzadeh et al., Adv. Mater. 35, e2209244 (2022). Copyright 2022 John Wiley and Sons.90 (f) Schematics of an electro-blown spinning setup, a hybrid manufacturing setup consisting of electrospinning and solution blow spinning. Reproduced with permission from Cao et al., Adv. Mater. 33, e2102500 (2021). Copyright 2021 John Wiley and Sons.91 (g) Schematics design of immersion rotary jet-spinning platform. Reproduced with permission from Gonzalez et al., Matter 3, 742 (2020). Copyright 2020 Elsevier.92 (h) Schematics of freeze spinning, a combination of directional freezing with solution spinning methods. Reproduced with permission from Cui et al., Adv. Mater. 30, e1706807 (2018). Copyright 2018 John Wiley and Sons.93 (i) Schematics of laser-assisted solution blow spinning setup. Reproduced with permission from Yang et al., Nano Lett. 22, 7212 (2022). Copyright 2022 American Chemical Society.94