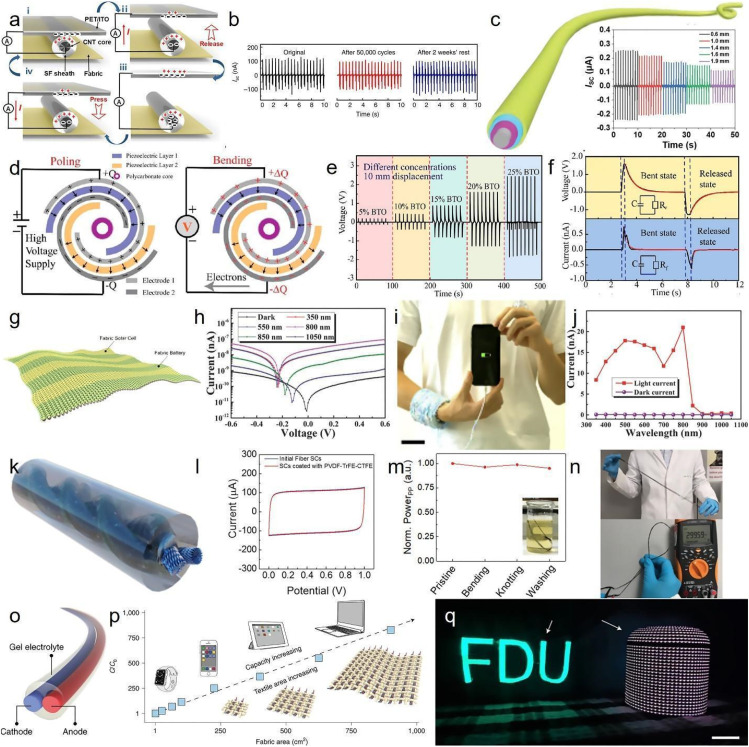

FIG. 7.

Power management using fibers. (a) Schematic illustration of the working mechanism for fiber-based triboelectric nanogenerators (TENG). Reproduced with permission from Zhang et al., Matter 1, 168 (2019). Copyright 2019 Elsevier.74 (b) Output evaluation and long-term stability of TENG fibers after subjecting it to continuous pressing for 50 000 cycles, and being stored in the ambient atmosphere for 2 weeks (contact length: 3 cm). (c) Schematics illustration of multi-layer TENG fibers. (b) and (c) Reproduced with permission from Dong et al. Nat. Commun. 11, 3537 (2020). Copyright 2020 Authors, licensed under a Creative Commons Attribution (CC BY) license.48 (d) Schematics of power generation through piezoelectric fibers. (e) Open-circuit voltage produced by a BaTiO3-poly(vinylidene fluoride) fiber that is 10 cm long and has varying BaTiO3 concentrations (5%, 10%, 15%, 20%, and 25% by weight) when subjected to a 1 cm displacement. (f) Open-circuit voltage and short-circuit current of the piezoelectric fiber, measured during its bending and releasing actions. (d)–(f) Reproduced with permission from Lu et al., ACS Nano 11, 2103 (2017). Copyright 2017 American Chemical Society.139 (g) Schematic diagram of photo-rechargeable fibrous battery. Reproduced with permission from Zhang et al., Matter 2, 1260 (2020). Copyright 2020 Elsevier.140 (h) Current–voltage curve of the photodetector, obtained under different wavelengths of light and in darkness. Reproduced with permission from Sun et al., Adv. Mater. 30, e1706986 (2018). Copyright 2020 John Wiley and Sons.141 (i) Charging a cell phone using photo-rechargeable fabrics. Reproduced with permission from Zhang et al., Matter 2, 1260 (2020). Copyright 2020 Elsevier.140 (j) Dependence of photocurrent and dark current on different wavelengths of irradiated light. Reproduced with permission from Sun et al., Adv. Mater. 30, e1706986 (2018). Copyright 2020 John Wiley and Sons.141 (k) Schematic demonstration of a fibrous supercapacitor. (l) CV curve for a fibrous supercapacitor with scan rate of 10 mV s−1 from 0 to 1 V. (m) Stable power generation of fibrous supercapacitor under a variety of mechanical stresses. (n) Potential charged in fibrous supercapacitors and their integration at scale. (k)–(n) Reproduced with permission from Cho et al., Adv. Funct. Mater. 30, 1908479 (2020). Copyright 2020 John Wiley and Sons.142 (o) Schematics of three-component extruded battery. (p) Linear increase for discharge capacity of fibrous energy storage textile with fabric area. (q) Powering textile display (left) and smart sound box (right) using textile batteries. (o)–(q) Reproduced with permission from Liao et al., Nat. Nanotechnol. 17, 372 (2022). Copyright 2022 Springer Nature.143