Table 1. Optimization of the GBB-3CR Conditionsa.

| entry | catalyst | solvent | temperature ( °C) | time | yields (%) |

|---|---|---|---|---|---|

| 1 | Sc(OTf)3(0.2) | MeOH | r.t. | 12 h | 45 |

| 2 | Sc(OTf)3(0.1) | MeOH | r.t. | 12 h | 49 |

| 3 | Sc(OTf)3(0.2) | MeOH | 100 | 2 hb | 39 |

| 4 | Sc(OTf)3(0.1) | MeOH | 100 | 2 hb | 60 |

| 5 | Sc(OTf)3(0.1) | MeOH | 100 | 1 hb | 51 |

| 6 | Sc(OTf)3(0.1) | MeOH | 100 | 4 hb | 44 |

| 7 | Sc(OTf)3(0.1) | MeOH | 100 | 2 hc | 49 |

| 8 | Sc(OTf)3(0.1) | EtOH | 100 | 2 hb | 53 |

| 9 | Sc(OTf)3(0.1) | toluene | 100 | 2 hb | 44 |

| 10 | Sc(OTf)3(0.1) | MeCN | 100 | 2 hb | 28 |

| 11 | La(OTf)3 | MeOH | 100 | 2 hb | 38 |

| 12 | Gd(OTf)3 | MeOH | 100 | 2 hb | 35 |

| 13 | HClO4(0.15) | MeOH | r.t. | 12 h | 37 |

| 14 | HClO4(0.15) | MeOH | 100 | 2 hb | 34 |

| 15 | AcOH(2) | MeOH | r.t. | 12 h | 20 |

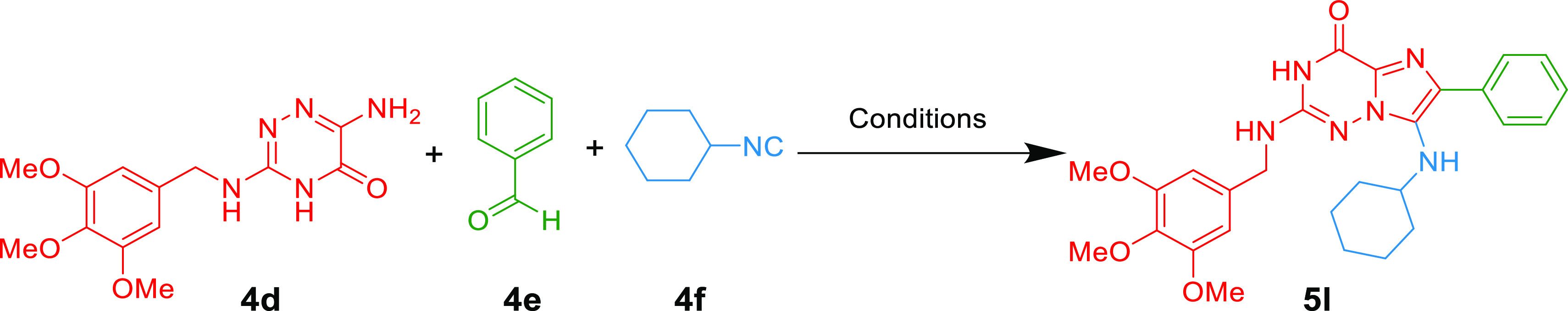

Reaction conditions: 4d (0.5 mmol), 4e (0.6 mmol), 4f (0.6 mmol), catalyst (10 or 20 mmol %), and solvent (2 mL).

Microwave condition.

Conventional heating using aluminum heating blocks.