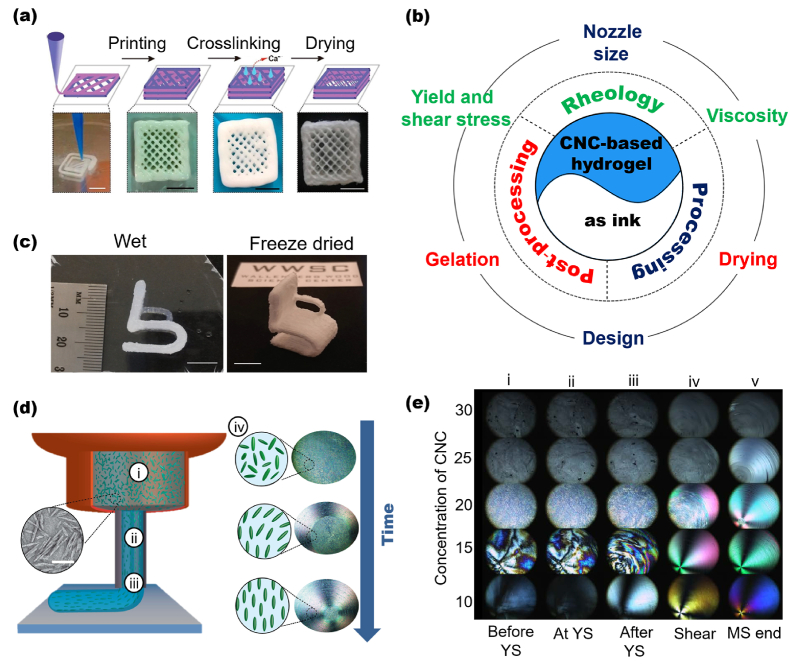

Fig. 2.

(a) 3D printed CNF-based cubic scaffolds (scale bar is 5 mm). (b) Main parameters that must be taken into account when preparing a material by 3D printing. Green: rheological properties (i.e., viscosity and shear stress); blue: processing (i.e., nozzle size and fabrication time); red: post‐processing (i.e., gelation and drying). (c) 3D printed small chair based on nanocellulose showing the high level of detail after freeze-drying. The scale bar corresponds to a 10 mm. (d) Scheme showing that 3D printing nozzles combined with shear and extensional flow can be used to tune the orientation of CNC. (di) CNC randomly organized; (dii) Aligned CNC due to maximized shear stresses through the nozzle; (diii) Final oriented extruded segment. (div) Alignment of CNC observed by polarized light imaging. (e) Alignment of a CNC as a function of concentrations and shear-stress. (ei) Before, (eii) at, and (eiii-iv) after yield stress (YS); (ev) at the end of the measurement. (a) Adapted from Ref. [95] with permission of Copyright 2019 American Chemical Society. (b) Inspired from Ref. [96]. (c) Adapted from Ref. [97] with permission of Copyright 2016 Wiley-VCH. (d–e) Adapted from Ref. [98] with permission of Copyright 2018 American Chemical Society.