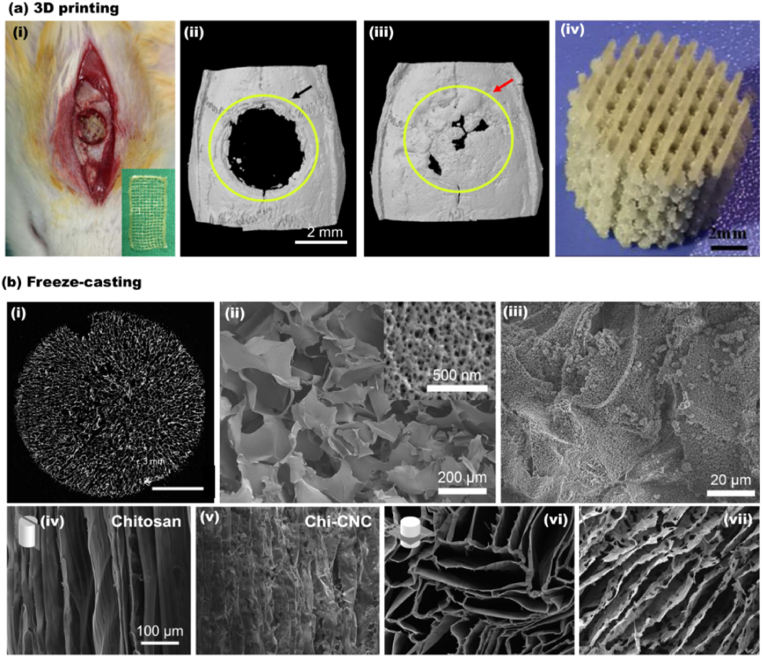

Fig. 6.

CNC containing 3D composites generated by 3D printing and freeze-casting. (a) 3D printed composite: (ai) The digital photograph of in vivo surgical examination with 3D printed CNC containing composite (CNC/Alg/Gel). The bone regeneration after 3 weeks in rat calvaria defect model. (aii) the negative control, and (aiii) the healed section [189]. (aiv) High fidelity 3D printed PLLA/CC composite [191]. (b) The 3D structures obtained by freeze-casting. (bi) A 2D slice of macroporous CNC structure. (bii) The cross-section SEM image of the macroporous aerogel at low and higher magnification (indicating the mesoporous CNC flakes). (biii) HA formation and coverage of CNC aerogel after CaCl2 pre-treatment and submersion in SBF for 7 days [122]. SEM images of a longitudinal cross-section of (biv) chitosan and (bv) chitosan-CNC scaffold frozen at the cooling rate of 10 °C/min. The SEM images of a transverse cross-section of (bvi) chitosan and (bvii) chitosan-CNC froze at a similar cooling rate of 10 °C/min (ai-iii) Adapted from Ref. [189] with permission of Copyright 2021 Elsevier. (aiv) Adapted from Ref. [191] with permission of Copyright 2020 Elsevier. (bi-iii) Adapted from Ref. [122] with permission of Copyright 2019 Elsevier. (biv-vii) Adapted from Ref. [192] with permission of Copyright 2019 American Chemical Society.