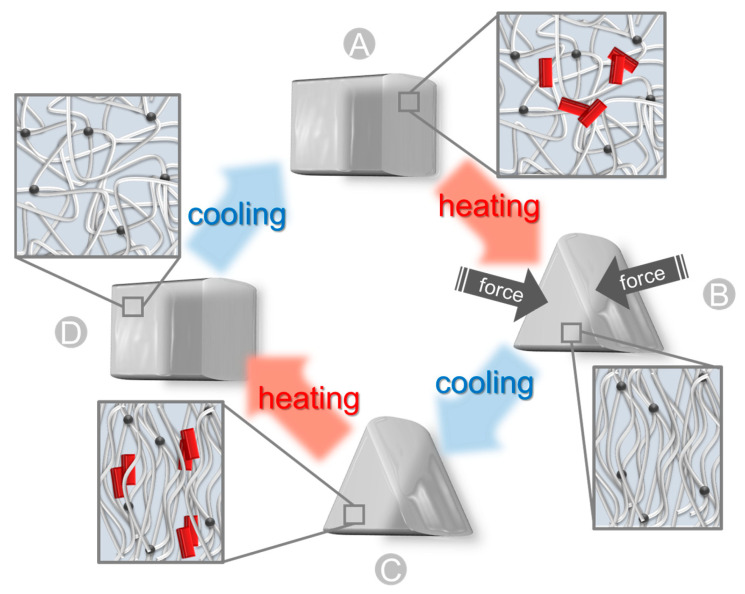

Figure 10.

Shape-memory effect; here shown for a material using crystallization for fixing the temporary shape, though other options exist. The original shape (A) of a material is heated above the melting temperature of crystalline domains (red, acting as temporary netpoints). Then, the material can be deformed into shape (B) resulting in the orientation of the polymer chains. When the temperature is decreased, crystallization is induced, and the temporary shape (C) can be obtained after removal of external stress. The recovery process is initiated by temperature increase enabling the polymer chains to regain their random coil formation. As result, a directed movement to the original shape (D) can be realized.