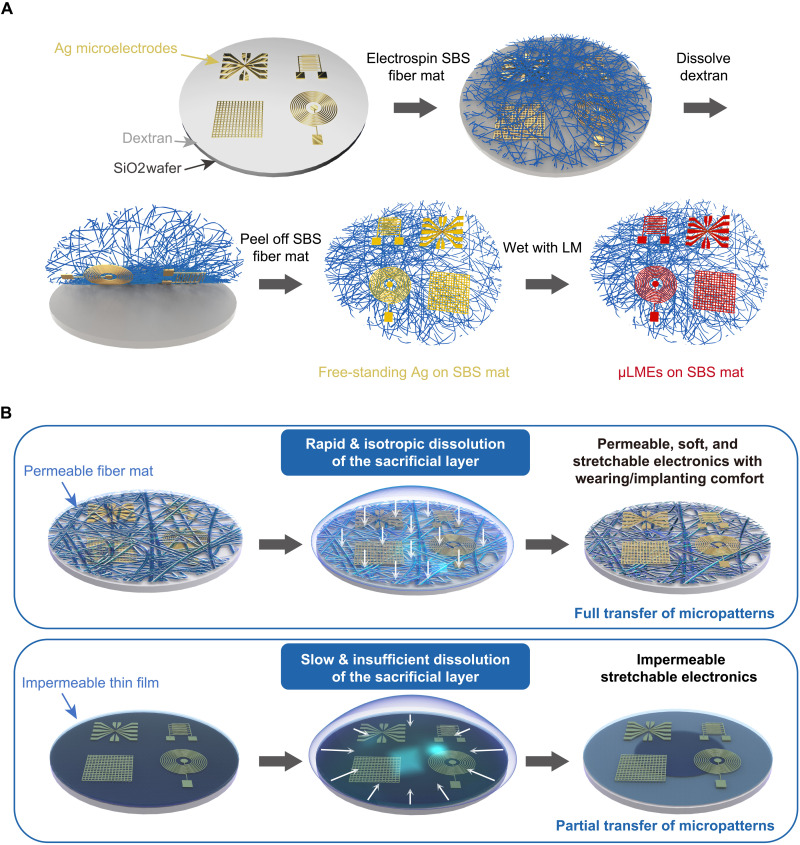

Fig. 1. Fabrication process of stretchable and permeable liquid metal microelectrodes (μLMEs).

(A) Schematic illustration of the fabrication process of μLMEs, which consists of four main steps: (i) photolithography of Ag on a SiO2 wafer premodified with a thin layer of water-soluble dextran, (ii) electrospinning of a fibrous SBS mat onto the Ag micropatterns, (iii) dissolving of the dextran layer and transfer of the Ag micropatterns from the SiO2 wafer onto the SBS fiber mat, and (iv) selective wetting of LM on the Ag-covered areas to generate μLMEs. (B) Schematic comparison of the different dissolution processes of the sacrificial layer by using permeable fiber mats or impermeable thin films. The use of permeable substrate significantly improves the contact area between the sacrificial layer and the solvent because the solvent can easily penetrate the porous fiber network. Therefore, the sacrificial layer can be fully dissolved in a short time in an isotropic manner, and the Ag micropatterns can be fully transferred. In contrast, the solvent can only contact the sacrificial layer from the edge of the substrate when using impermeable thin film substrates, e.g., PDMS, resulting in the slow and insufficient dissolution of the sacrificial layer and thus the partial transfer of the Ag micropatterns.