Abstract

Food is a crucial source for the endurance of individuals, and quality concerns of consumers are being raised with the progression of time. Edible coatings and films (ECFs) are increasingly important in biobased packaging because they have a prime role in enhancing the organoleptic characteristics of the food products and minimizing the spread of microorganisms. These sustainable ingredients are crucial for a safer and healthier environment. These are created from proteins, polysaccharides, lipids, plasticizers, emulsifiers, and active substances. These are eco-friendly since made from innocuous material. Nanocomposite films are also beginning to be developed and support networks of biological polymers. Antioxidant, flavoring, and coloring compounds can be employed to improve the quality, wellbeing, and stability of packaged foods. Gelatin-enhanced fruit and vegetable-based ECFs compositions have the potential to produce biodegradable films. Root plants like cassava, potato, and sweet potato have been employed to create edible films and coatings. Achira flour, amylum, yam, ulluco, and water chestnut have all been considered as novel film-forming ingredients. The physical properties of biopolymers are influenced by the characteristics, biochemical confirmation, compatibility, relative humidity, temperature, water resistance, and application procedures of the components. ECFs must adhere to all regulations governing food safety and be generally recognized as safe (GRAS). This review covers the new advancements in ECFs regarding the commitment of novel components to the improvement of their properties. It is expected that ECFs can be further investigated to provide innovative components and strategies that are helpful for global financial issues and the environment.

1. Introduction

Biobased packaging acquired much importance in the past few years.1 Edible films are narrow sheets applied to products.2 This is made from eco-friendly safe material. Edible coatings are produced by a number of different techniques and have a great impact on preserving the nutrients such as flavoring agents, antioxidants, and antimicrobials.2 Functionality largely depends on their permeability, solubility, and mechanical properties. Employment of edible coatings and films (ECFs) is not a brand new technique; it has been used since prehistoric times. ECF is a comprising technique with a positive effect on quality conservancy.3

A partial barrier against moisture retention can be provided by an edible coating.4 ECFs are made from entirely sustainable and safe materials.5 Selection of sustainable materials for ECFs have a great impact on the formation of efficacy and user adequacy.6 Increasing consumer demand for food preservation from biological sources has led to modified techniques including ingestible biopolymers. Proteins, polysaccharides, and lipids might be considered the main ingredients in the synthesis of ECFs. A combination of the insignificant materials as plasticizers, emulsifiers, and vigorous ingredients, specifically antimicrobial and antioxidants, can be employed to enhance their efficacy. The processing of the commodities comes after harvesting, and packaging is a crucial step that is required to maintain the quality parameters of the products in terms of their organoleptic properties, physio-chemical properties, and sensory properties. Packaging also helps to improve distribution and transportation of the commodities. Food packaging protects the food from any kind of external damage without interacting with the internal environment of the product. External damage would be any kind of physical damage (shocks), chemical damage (temp, pH), and biological damage (damage caused by micro-organisms, insects, and animals).7 Most of the fruits and vegetables are highly perishable and some climacteric fruits which undergo their ripening process during and even after harvesting have shorten shelf life and are more prone to microbial attack, oxidation, and browning. To address these issues, food packaging of mainly the petroleum-based plastic packaging is extensively used but these are nondegradable and are not environmentally friendly. Biodegradable packaging materials have gained researchers interest as they are food-grade, environmentally friendly, and can be consumed with the product. Chitosan-based edible coatings have good antimicrobial, antifungal properties, and film-forming properties. In order to maintain and enhance the safety and quality characteristics of the products, chitosan, a fundamental coating material made of proteins and polysaccharides, is being employed as an alternative to plastic packaging.8

Dextran- and chitosan-based biopackaging had been used for mushrooms (Agaricus bisporus). These films exhibit good mechanical attributes in term of moisture resistance and gas permeability. These films also have antimicrobial potential, are made from safe material, and are biodegradable. Dextran and chitosan are generally recognized as safe material and are safe renewable material. These materials do not impart undesirable odor and taste to food materials. These films also exhibit good transparency and allow the visual inspection of food commodities. Dextran- and chitosan-based films help to enhance the quality and extend the shelf life of mushrooms (Agaricus bisporus).9 Characterization of oligodextran produced by Leuconostoc mesenteroides SF3 and its effect on film-forming properties of chitosan provide valuable insights on the potential applications of this film blend, including information about the rheological attributes, molecular weight distribution, and degree of polymerization. Oligodextran also helps to access the film-forming abilities, mechanical attributes, and functional properties of film.10

Edible coatings and films are used to improve the appearance of the food and promote the health of the food through environmentally friendly properties.11 The addition of biobased polymers also brings some challenges to some food.12 As fresh or lightly processed fruit and vegetables gain popularity because of their increased biological relevance and health benefits, the consumer’s demand for nonchemically preserved, superior quality foods have been steadily rising.13 The quality and well-being of fruits and vegetables typically diminish in the course of postharvest losses because of increased humidity content, maturing, senescence, bacteriological growth, and ecological factors.14 The use of edible films and coatings helps to reduce them.13 ECFs are employed to restore the organoleptic features of packaged foods.15 ECFs can also effectively reduce microbiological development in firm and semisolid food items by reducing the transmission rate of antimicrobial components from glazing material to food product. This is due to their effectiveness as discriminating barriers to gas, humidity, and solute transport.16

2. Conformation of ECFs

Currently, artificial and petroleum materials are reinstated with sustainable materials in the packing sector.17 Solutions with a mixture of different natural components are applied for the manufacturing of ECFs (Figure 1). ECFs are categorized based on the structural components, such as proteins, lipids, polysaccharide films, or composite materials.18 The mechanical properties of ECFs are influenced by the polymer matrix or compatibility of the material. The mixture of lipids and hydrocolloid mass may form a composite film. Tannic acids are mostly used in edible coating and films as a strong polyphenol, mainly extracted from different parts of plant tissues and green tea. Tannic acid has hydrogen bonding and dynamic covalent interactions between five gallol and five catechol groups, and consequently, it has higher water permeability, better mechanical strength, and powerful antioxidant, antibacterial, and antiviral properties.19 Tannic is used as a cross-linking agent in most edible coatings and films to improves the strength and mechanical properties because of the covalent bonds and covalent cross-linking with the coating materials. The tannic acid-based films and coating strongly reduces the weight loss, oxidation, and browning of the products.20 Tannic acid is generally considered safe and is biocompatible. Tannic acid has the capability to effectively cross-link polymers under mild conditions and can also cross-link with multiple functional groups.21 It has excellent antimicrobial and antioxidative attributes which are very helpful, but there is an issue regarding the toxicity of tannic acid.22 Tannic acid has pH sensitivity and is sensitive to light and oxidation. Exposure to oxygen may result in different color changes. To overcome this problem these is a need for proper handling and storage and proper packaging. pH optimization is another method to overcome this problem of tannic acid. Coating and encapsulation are potential to ways to prevent leaching and migration of tannic acid from the film.23,24

Figure 1.

Film casting method used in the lab to produce edible films.

2.1. Protein-Based ECFs

The specific amino acid components that make up a protein are contained in biopolymers created by deamination relapse.25 The protein denaturation process is done during the film formation.5 A resilient, interconnected, and viscoelastic film can be formed while proteins interrelate with adjacent particles by hydrogen, ionic, or covalent linkage after denaturation. The basic material for the manufacture of protein-based ECFs can be from animal or plant-based sources as shown in (Figure 2). Due to their biological value, biodegradability, and amazing film-creating abilities, biopolymers are the best option for films and coating formulations.26 Zein, a plant protein, can be used to benchmark infectious contaminations and decays in fruits and vegetables.27 Conformation, plasticity, and thermal permanence of protein are very significant to create films.28 Protein-based ECFs provide a tremendous barrier to gases. These biopolymer-based ECFs improved mechanical properties associated with those emerging from lipids and carbohydrates. Protein-based ECFs have significant drawbacks, including a lack of water vapor barrier components.25

Figure 2.

Protein-based materials used for edible coatings and films.

The creation of edible films and coatings frequently uses milk proteins. Because milk includes a lot of lactose, which causes crystallization in the film, only whey protein should be used instead of entire milk proteins.29 Whey protein is used as an emulsifier and plasticizing agent in two forms mainly the whey proteins concentrate and whey protein isolates. Whey protein-based film is used in low humidity conditions and has high oil barrier properties and high aroma of oxygen. Whey proteins are also used in edible coatings and films as a probiotics and prebiotics source.30 Milk proteins are very important and valuable biopolymers. These have higher thermal stability and are nontoxic. Milk proteins have remarkable gas barrier properties because they have unique structure. Along with these beneficial characteristics there are also some downfalls of milk-based proteins which include moisture sensitivity and low elasticity. To get maximum benefits from milk-based proteins, it is advisible to select the correct milk protein source and use to appropriate reinforcing agents.31

Zein, a protein that can be obtained from gluten or created during the bioethanol manufacturing process, is widely employed in edible coatings and films. Zein is used with other polysaccharides and protein-based films such as with galactomannans to enhance barrier properties and imparts gloss glass surface. To improve the barrier properties, zein is used with protein-based films through the protein–protein bounding. Zein contains a balance assembly of hydrophobic and hydrolytic structures.29 Zein scaffolds have remarkable potential for tissue engineering. Zein protein has the ability for stability of molecules. This protein also has potential for controlled drug delivery. The zein protein have potential for usage in applications at the nano level.32

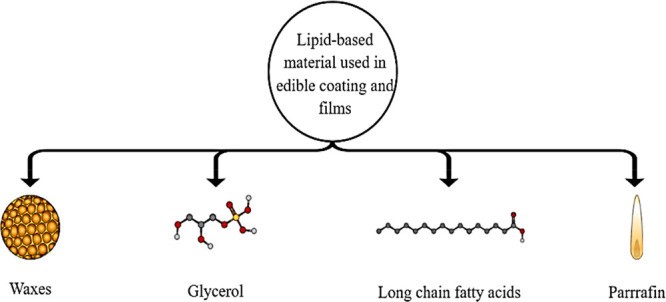

2.2. Lipid-Based ECFs

Hydrophobic lipids are small biological molecules, unsolvable in water. Due to hydrophobicity, lipid-based ECFs are superfluously brittle and denser. These have exceptional barriers in contradiction to moisture migration.5 ECFs comprising lipids in alginate extracts were manufactured by Fabra and coauthors.33 Materials applied in the manufacture of films and coatings comprise waxes, paraffin, and acetoglyceride, as mentioned in Figure 3. The main drawback of lipid-based ECFs is the restriction of the finished food product appearance and perception.

Figure 3.

Lipid-based materials used for the production of edible coatings and films.

2.3. Polysaccharide-Based ECFs

Polysaccharide-based ECFs are tough, highly soluble, colorless, and flexible because polysaccharides have linear structures.25 These films could be smeared in numerous food to prolong the shelf life of foodstuffs, such as fruit and vegetables, and meat (Figure 4). Polysaccharide that are mostly used in film formation are chitosan, alginate, and gums. Polysaccharide-based ECFs have noble gas impermeable properties, and effective oxygen blockers, just because of their well-organized hydrogen-bonded linkage. Incompetence as moisture barriers is their major drawback.25 Deacetylation of chitin by alkali solution provides chitosan. Chitosan is also obtained from invertebrates, insects, marine organisms, algae, and fungi.34 Chitosan has exceptional antimicrobial, antioxidant, O2, and CO2 barrier attributes.35 Solutions with a mixture of different polysaccharide components are applied as edible coatings on fruits and vegetables. Chitosan came up smeared in the cast of extricating or nanoparticles in biologically active layers along with peel extricate of pomegranate for the protection of fruits from fungi in 2019.36 Other research was conducted in which edible coatings were produced using chitosan or olive oil extracts, which prevent microbiological activity in apples and strawberries.37

Figure 4.

Polysaccharide-based materials used to produce edible coatings and films.

ECFs made of algae tend to enhance the qualities and lengthen the shelf life of dairy products, cheese, meat, and other fresh produce. A study by Rangel-Marrón and co-workers assessed the impact of applying ECFs with sodium alginate to papaya blends.38 Another study focused on the representation of sodium alginate coatings that were reinforced using lemongrass natural ointment to be applied on fresh apple slices in order to maintain the quality of the products.39 Gums are hydrophilic which are tasteless, unscented, monochrome, nontoxic, eco-friendly, sustainable, and biologically safe. These characteristics of gums caused a rise in the demand for this substance.40 These can be arranged on the basis of their origin, shape, charge, and synthetic design.41

2.4. Composite Films

There are several drawbacks to all biopolymers used in food packaging; to address this, composite or multicomponent films are created. It comprises a blend of various materials with useful properties.5 A few combinations are feasible to upgrade a few obstructions and mechanical properties like protein–protein ECFs, polysaccharide-protein ECFs, and polysaccharide-lipid ECFs. At the point when ECFs with a blend of alginate besides chitosan were developed, palatability and sensory characteristics of new figs were obtained, in addition to their bioassay properties and barrier properties. Composite ECFs were also recently cast-off in another investigation to ensure the quality of grapes during storage.42 Nowadays, nanocomposite films are arising as one more bundling arrangement and comprise the support of the biological polymer network through nanocrystals that allow for work on their strength, isothermal, and boundary properties. This procedure is static in an undeveloped stage and is important to plan and foster improved handling innovations.26

2.5. Plasticizers

Broad connections among the biological polymers can prompt an inflexible design and fragility in the ECFs creation. It tends to be tackled by integrating plasticizing agents into preparations.26 Plasticizers are tiny, relatively stable particles. These substances cause the film to stretch more and lose flexibility. Because of the greater mobility of the polymeric compounds, which can limit the usage of this kind of mixture, the use of plasticizers in higher levels may hasten the arrival of the powerful complexes like antioxidants and antimicrobials present in the combination.35 The similarity between the compounds’ nature, size, and constituent composition is anticipated to prevent the plasticizing chemical from shifting from the film framework when they are used. The most widely used plasticizer is glycerol.18 Glycerol is used to lessen the brittleness of the biocomposite ECFs made from the psyllium coating.43 Using chitosan films, nuts, seeds, and fruits can be shielded from fungal contaminations.44

2.6. Additives

The strength, palatability, and healthful qualities of ECFs can be improved by chemical additives such plasticizers and surfactants by enhancing the utility of the package. To advance stabilizing and mechanical properties, emulsifiers can also be applied. Table 1 represents the benefits along with the properties of edible coatings. Antimicrobial, antioxidant, flavoring, and coloring agents can be engaged to boost the excellence, well-being, and stability of packaged food.5

Table 1. Beneficial Properties of ECFs.

| benefits | properties | refs |

|---|---|---|

| moisture barrier | prevent moisture loss | (45, 46) |

| prevent aroma loss | ||

| good storage stability | ||

| enhance texture | ||

| prolog shelf life | ||

| oxygen scavengers | control humidity | (47) |

| minimize oxygen diffusion rate | ||

| decrease respiration | ||

| delay oxidation | ||

| ethylene scavenger | extend shelf life | (48) |

| lower ethylene concentration | ||

| antimicrobial properties | minimize spoilage | (49, 50) |

| control microbial growth | ||

| extend shelf life | ||

| antibrowning and antioxidant properties | prevent discoloration | (51) |

| control polyphenol oxidase (PPO) activity | ||

| strong barrier for oxygen |

3. Novel Materials

3.1. Whole Grain Flour

Material for polysaccharides protein-based ECFs acquired from ordinary crops or roots. Researchers have developed numerous systems to manufacture films from this material.52 Several studies have demonstrated the ability of powders derived from whole grain components to produce biofilms, similar to amaranth53 and quinoa54 or chia.55 Some studies reported that psyllium husk and its flour are the finest to create films. Nouraddini developed composite film from eggplant flour or corn starch.56 Eggplant flour has exceptional film-forming ability but diminished mechanical properties. Legume flours have worthy film-forming material just because of their high starch and protein percentage. Additionally, edible films are successfully produced from grass peas, lentils,57 chickpeas,58 and mung beans.59 Cassava flour-based ECFs contain abundant fiber lentil powder. These films are biodegradable or thermally stable.60

3.2. Fruit and Vegetable-Based ECFs

Formerly, fruits and vegetable blends were used in coatings. Though, they still remain a focus of research. Other than carbohydrates, the characteristics of flour are examined in the food films made from plantains and bananas.61 The food business generates a significant amount of food waste each year. It contains a rich measure of supplements, bioactive mixtures, or dietary strands. Pomace and seed parts of certain organic products have higher cell reinforcement action than the mash divisions.62Carissa carandas fruit polysaccharides have preservative properties. These polysaccharides have a high content of bioactive compounds and exhibit excellent antimicrobial attributes. Modification of these polysaccharides by chemical means make them suitable to use in pharmaceutical and different food products.63 The processing cost of organic products or vegetables relies on applied technologies.64 Somewhat recently, the utilization of foods grown from the ground using parts of ECFs have been a significant topic.38 There are innovative ECFs made from powdered substances from different mixtures, such as those starting with orange, enthused natural ingredients, or lettuce. Without the use of plasticizers, the creators obtained uniform, adaptable films, which displayed promising qualities. Potato skin flour heightened mechanical confrontation.64Table 2 explains all the different coating materials used for edible coatings along with their compositions. The research led to the discovery that grapefruit luminosity is a film-shaping material, with countless practical attributes for ECFs.65 Gelatin-enhanced film compositions created by researchers have shown incredible inventive and practical promise for making biodegradable films. Nowadays researchers are exploring innovative extraction methods to increase the yield and purity of the extracts. These techniques include gel filtration, ion-exchange chromatography, membrane filtration, enzyme-assisted extraction, microwave, and ultrasound-assisted extraction. Plant leaf-extract polysaccharides can be used as functional ingredients. Different plant leaf-extract polysaccharides have antioxidative potential.66 The advantages and disadvantages of cross-linking agents used in the manufacturing of ECFs are shown in Table 3.

Table 2. Materials Used in the Manufacturing of ECFs.

| no. | material | type | composition | properties | refs |

|---|---|---|---|---|---|

| 01 | starch | polysaccharide-based | composed of amylose and amylopectin | improve physicochemical properties | (67) |

| improve optical properties | |||||

| colorless | |||||

| odorless | |||||

| low oxygen permeability | |||||

| low cost | |||||

| oil-free appearance | |||||

| decrease respiration rate of fruits and vegetables | |||||

| 02 | chitosan | polysaccharide-based | go through the process of deacetylation | antioxidative | (68) |

| antimicrobial | |||||

| nontoxic | |||||

| biodegradable | |||||

| biocompatible | |||||

| microbial resistance | |||||

| control transpiration rate | |||||

| retard ripening process | |||||

| 03 | alginate | polysaccharide-based | composed of sodium salt of alginic acid | good film forming properties | (67) |

| can form gels | |||||

| 04 | gellan gum | polysaccharide-based | consist of tetrasaccharide repetitive units | improve function properties | (67) |

| good hardness | |||||

| high transparency | |||||

| smooth surface | |||||

| reduction in water vapor permeability | |||||

| 05 | pullulan | polysaccharide-based | polysaccharide | powerful reducing agent | (67) |

| increase shelf life | |||||

| 06 | cellulose | polysaccharide-based | linear chain polysaccharide | low water solubility | (69) |

| 07 | carboxymethyl cellulose | polysaccharide-based | consist of glucopyronosyl units | excellent oxygen barrier | (67) |

| aroma barrier | |||||

| oil barrier properties | |||||

| antisenescence properties | |||||

| 08 | pectin | polysaccharide-based | heteropolymer made up of d-galacturonic acids units | water barrier properties | (70) |

| resistance to breaking | |||||

| higher thermal resistance | |||||

| 09 | corn zein | protein-based | prolamin protein | good film forming attributes | (67) |

| moisture resistance | |||||

| 10 | deep eutectic solvents (DES) | solvents | hydrogen bond donor and hydrogen bond acceptor made eutectic mixture | moisture barrier | (71) |

| solvent power | |||||

| biocompatibility | |||||

| enhanced mechanical attributes | |||||

| versatility | |||||

| sustainability | |||||

| antimicrobial potential | |||||

| 11 | dexibuprofen-loaded silica | dispersion | ternary solid dispersions of dexibuprofen by solvent evaporation | effective anti-inflammatory properties | (72) |

Table 3. Crosslinking Agents Used in the Manufacturing of ECFs along with Its Advantages and Disadvantages.

| no. | type of coating | cross-linking agents | advantages | disadvantages | refs |

|---|---|---|---|---|---|

| 01 | sodium alginate | Tannic acid | antioxidant and antimicrobial properties | used in high amount reduces the mechanical strength | (73) |

| 02 | glass coatings | Alcohol | UV-proofing property | development of blocking agents | (74) |

| 03 | dispersions and emulsions | Amines | high reaction rate of nucleophily | time-consuming | (75) |

| 05 | extract-based coatings | Zein fibers | encapsulate bioactive compounds, thermal stability | poor mechanical property and stability | (76) |

| 06 | protein-based coating | glutaraldehyde | food additives, cross-linked with proteins | several health hazards are associated with additives | (77, 78) |

| versatility | cross-linking sensitivity | ||||

| film integrity and stability | residual unreacted glutaraldehyde | ||||

| water resistance | |||||

| biocompatibility | |||||

| stability against enzymatic degradation | |||||

| 07 | starch and chiton | tannic acid | decreases water vapor permeability and mechanical strength | used in high amount reduces the mechanical strength | (23, 24) |

| biocompatibility | pH sensitivity | ||||

| versatile cross-linking capabilities | light sensitivity | ||||

| antioxidant properties | leaching | ||||

| antimicrobial attributes | migration | ||||

| precipitation and gelation |

3.3. Root Plants

Cassava, potato, and sweet potato have been used in the manufacturing of edible films and coatings. Novel film-forming materials were assessed utilizing achira flour79 or amylum from canna lily (Canna indica),80 yam (Dioscorea alata), ulluco (Ullucus tuberosus),81 or water chestnut.82 These films lack mechanical characteristics.

3.4. Plant Gums

Gum acacia is unique and is of the most outstanding, acknowledged among every single normal gum. It has worthy blending, soothing, gelling, and binding characteristics.83 Gum Acacia has been used in edible coating for improving functionality and emulsion stability like in pecan nuts. Coating of tomato with gum acacia presented a critical postponement in relation to variety, bulk reduction, immovability, titratable acidity, and rot rate.84 The same outcomes are observed in the cases of apples85 and strawberries.86 Almond gum is obtained through the bough of an almond tree. Exudate gums have the best physical, chemical, and biological properties to use as a coating.87 ECFs developed from Cajanus cajan (Cajanus cajan (L) Millsp) seeds, gum, and protein detach to expand the quality of coated strawberries.88

3.5. Wild Plants

Polysaccharides utilized in the ECFs are mostly amylum and fiber subordinates. A hydrophyte that could be used to obtain an ECF is the Opuntia cactus.89 Opuntia cactus inferred polysaccharides were applied to citrus organic products as an eatable covering. ECFs from Pereskia aculeata Miller mucilage leaves were developed.90 These films were elastic, dark in color, and plane exterior films. Used for chocolate or coffee beans. To improve the storage duration of beef slices,91 an edible coating from Shirazi balangu (Lallemantia royleana) seed was developed. Kim created edible films involving gulfweed in the two types of coverage for the utilization of smoked salmon.92

3.6. Deep Eutectic Solvents (DES)

Dep eutectic solvents (DES) are new generation green additives. These helps to improve the different properties of films, especially chitosan-based films.93 These solvents have excellent beneficial attributes including plasticization, improved mechanical attributes, enhanced thermal stability, and solubility enhancement. DES also have antimicrobial attributes that help to extend the shelf life of food materials.71 Application of DES for chitosan-based films is a recent research area. DES are safe chemical substances and have been recently used in the preparation of films because of better barrier attributes. DES help to preserve the sensory properties of food commodities.94 These green additives can also act as the carrier for the bioactive compounds delivery. These are also environmentally friendly substances.95 Nowadays, research is more focused in this area and more exploration is needed.

4. Physical Properties

Important attributes of biopolymers are the foundation, mechanical arrangement of the chain, and handling methodology. So in the application of biological polymers, it is vital to consider their physical and functional properties.96 Biopolymer films’ and coatings’ physical properties are determined by the components’ features. Biochemical confirmation and compatibility of all components are imperative to biopolymer properties. Relative humidity and temperature are also vital. The difference in water humidity stands out more clearly, and the amount of water vapors that permeate a film is more significant. Synthetic coatings have lower water vapor penetrability as compared to other films. Water resistance is impacted by film thickness.96

5. Application Methods for ECFs

The technique and way of coating application are very imperative. The suitable technique assures the thorough casing of the product and subsequently prolongs the shelf life.97 Different strategies for their application are brushing, individual wrapping, spreading, and fluidized-bed handling. The fundamental strategies utilized for food covering are spraying and dipping. ECFs should be consistent and free of faults.98

5.1. Dispersion and Electrostatic Dispersion

The technique encompasses a drizzle of the product’s whole surface with a coating solution, a less viscous solution used with a pressure of 60–80 psi.99 Dispersion is done by using a spray gun.100 The standard spray method produces fine spray with a 20 μm drop size. The electrostatic dispersion method generated constant units. Critical features for film formation comprise desiccating period, temperature, and technique. To achieve even coating spraying, cogitate is the most effective79 (Figure 5).

Figure 5.

Application of coating by dispersion technique.

5.2. Immersion Technique

In the immersion technique method, covering is smeared on by plunging the food item in ECF solution (Figure 6). It is an applicable technique for products with uneven surfaces. By this technique, dense coatings can be acquired. Biopolymer coating can be affected by the density and tackiness of the coating solution.97 In dipping, food is straightforwardly submerged into a solution and released subsequently following a certain period.99 The period is generally 5 to 30 s, after which the product is dried naturally. Optimal regularities can be acquired by using this technique. The drawback of this method includes hindrance in reparation due to thick coating or coating solution and can lower the functionality of food surface by weakening the outer covering. In the implementation of the ECFs, it is challenging to accomplish suitable adhesion properties.

Figure 6.

Application of coating by immersion technique.

6. Well-Being Issues, Protocols, And Legislation

ECFs ought to follow all expected guidelines appropriate to foodstuff constituents because these are a fundamental measure of the eatable serving.101 All ECFs producing components, or any effective additions, should be generally recognized as safe (GRAS) to maintain product safety and ingestion prominence. Some edible films comprise materials that can probably cause hypersensitive responses. Therefore, regardless of how little is used, an ECF containing a significant toxin should also be announced to the customer and a suitable warning should be given.102 Every component used in coatings should be approved by users based on their sensory perception.103 Additionally, the toxicity and genotoxicity of ECFs should be taken into account during assembly as yet another important factor. In such circumstances, organic oils that are frequently used in ECFs as a germicidal complex, although being defined or enrolled as GRAS by the European Commission and the United States, may introduce hypersensitive effects.100 There are rules for adding antioxidants and antimicrobials that are applicable to food compositions.104Table 4 explains the applications of EFCs on different food products.

Table 4. Application of ECFs on Selected Food Products.

| no. | food product | coating materials | impact on food product | refs |

|---|---|---|---|---|

| 1 | mango | glycerol | prevent loss of firmness and weight | (105) |

| carnauba wax | reduce color changes | |||

| aloe vera | reduce changes in pH and Brix value | |||

| control the rate of respiration | ||||

| 2 | guava | alginate | shelf life enhancement | (106) |

| chitosan | ||||

| 3 | avocado | carboxyl methylcellulose (CMC) | prevent firmness loss and weight loss | (6) |

| antimicrobial properties | ||||

| shelf life enhancement | ||||

| 4 | tomatoes | pectin | lower weight loss | (6) |

| shelf life enhancement | ||||

| 5 | strawberries | beeswax | fungal infection prevention | (107) |

| chitosan | reduced weight loss | |||

| lowers the respiration rate | ||||

| 6 | figs | chitosan | improve antioxidant properties | (108) |

| delaying in color change | ||||

| alternaria alternata growth was repressed | ||||

| 7 | bell pepper | chitosan | no modification in flavonoids and antioxidant capacity | (109) |

| slow growth of Alternaria alternata | ||||

| 8 | kiwi (freshly cut) | mucilage of cactus pear | improve flavor | (110) |

| visual quality enhanced | ||||

| shelf life extension | ||||

| 9 | blueberries | alginate | improved sensory quality | (111) |

| chitosan | shelf life extension | |||

| apple fiber | delayed ripening | |||

| orange fiber | maintenance of flavor, texture, and appearance | |||

| chitosan | ||||

| calcium caseinate | ||||

| alginate | ||||

| semperfresh | ||||

| 10 | jackfruit (freshly cut) | xanthan gum | microbial growth repressed | (112) |

| shelf life extension | ||||

| 11 | pineapple (freshly cut) | alginate | quality conservation | (113) |

| shelf life extension | ||||

| 12 | apples (freshly cut) | carboxymethyl cellulose (CMC) | shelf life extension | (114) |

| chitosan | antioxidant capacity of vitamin C was maintained | |||

| alginic acid and gellan gum | quality enhancement | |||

| fiber from apple and pectin | ||||

| 13 | potatoes | locust bean gum | microbial growth controlled | (115) |

| nutritional quality maintained | ||||

| 14 | watermelon (freshly cut) | alginic acid | improved texture | (116) |

| polysaccharide (pectin) | shelf life extension | |||

| calcium lactic acid | ||||

| 15 | fresh-cut mangoes | alginate | browning delayed | (117) |

| shelf life extension | ||||

| 16 | saffron | maltodextrin | improvement of physicochemical properties | (118) |

| nanocellulose | ||||

| 17 | taro corms | chitosan | quality improvement | (119) |

| starch | microbial growth inhibited | |||

| shelf life extension | ||||

| 18 | cherry tomatoes | hydroxypropyl | reduction in fungal growth | (120) |

| methylcellulose | botrytis cinerea growth was reduced | |||

| beeswax | ||||

| 19 | mushrooms | alginic acid | shelf life extension | (121) |

| 20 | leaves of spinach | agar gewl | shelf life extension | (122) |

| carrageenan | ||||

| 21 | asparagus (white) | na | reduction in weight loss | (123) |

| carboxymethyl-cellulose (CMC) | quality preserved | |||

| isolate of whey protein | ||||

| 22 | sausages | maltodextrin | shelf life extension | (124) |

| alginate | reduction in weight loss | |||

| carboxymethyl cellulose (CMC) | ||||

| gelatin | ||||

| carrageenan | ||||

| 23 | butter | low-density polyethylene | increased antimicrobial properties | (125) |

| increased antioxidant capacities | ||||

| shelf life extension | ||||

| 24 | bread | pectin | lower moisture content | (126) |

| alginate | shelf life extension | |||

| whey protein | ||||

| starch | ||||

| 25 | chicken meat | powder of peel of mango | shelf life extension | (127, 128) |

| arabic gum | bioactive compounds were improved | |||

| PE low density | antimicrobial capacity was improved | |||

| 26 | slices of ham | starch from cassava tuber | storage-life extension | (129) |

| polysaccharide (chitosan) | ||||

| 27 | chicken nuggets | alginate | microwave heating was enhanced | (130) |

| 28 | Chicken breast (freshly cut) | carrageenan | reduction in Campylobacter jejuni | (131) |

| polysaccharide (chitosan) | shelf life extension | |||

| 29 | cheese | galactomannan | shelf life extension | (132) |

| chitosan | ||||

| 30 | bream fish | alginate | bacterial growth inhibited | (133) |

| enhanced sensory values | ||||

| shelf life extension | ||||

| 31 | turkey (pouched) | alginic acid | growth of microorganisms was inhibited | (134) |

| carrageenan | ||||

| polysaccharide (starch) |

7. Conclusion

In conclusion, edible films and coatings have emerged as a promising method to raise food quality, enhance shelf life, and reduce environmental waste. They frequently consist of natural polymers such as proteins, polysaccharides, and lipids and have several benefits, including the capacity to preserve food freshness, halt moisture loss, and prevent microbial contamination. They also provide an alternative to traditional packaging materials, which are frequently nonbiodegradable and contribute to plastic litter. Edible films and coatings have the potential to decrease food waste by keeping the freshness and safety of perishable foods. They also create a barrier to oxygen, moisture, and other outside elements, slowing the deterioration process and extending product shelf life. The growing consumer desire for organic and sustainable food items is another significant factor, as they are made from renewable resources and are simple to incorporate into the current food manufacturing processes. The exploration of novel materials and future advancements in formulation techniques are anticipated to define the trend toward edible films and coatings. Researchers and industry experts are expected to concentrate on improving these films’ and coatings’ mechanical qualities, barrier capabilities, and stability in order to boost their usefulness and acceptability for usage in a variety of food applications. Additionally, efforts to develop edible films and coatings with enhanced antibacterial properties are likely to continue. The production of edible films and coatings using nanotechnology appears to be a potential area for future study. Food packaging and preservation will probably become more environmentally friendly and sustainable when these materials see increasing advancements and are used widely in the food industry.

Acknowledgments

The first author extends his appreciation to all coauthors for their contribution.

Author Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

The authors declare no competing financial interest.

References

- Chakravartula S. S. N.; Soccio M.; Lotti N.; Balestra F.; Dalla Rosa M.; Siracusa V. Characterization of composite edible films based on pectin/alginate/whey protein concentrate. Materials 2019, 12 (15), 2454. 10.3390/ma12152454. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bizymis A.-P.; Tzia C. Edible films and coatings: Properties for the selection of the components, evolution through composites and nanomaterials, and safety issues. Crit. Rev. Food Sci. Nutri. 2022, 62 (31), 8777–8792. 10.1080/10408398.2021.1934652. [DOI] [PubMed] [Google Scholar]

- Tonyali B.; Cikrikci S.; Oztop M. H. Physicochemical and microstructural characterization of gum tragacanth added whey protein based films. Food Res. Int. 2018, 105, 1–9. 10.1016/j.foodres.2017.10.071. [DOI] [PubMed] [Google Scholar]

- Jongsri P.; Wangsomboondee T.; Rojsitthisak P.; Seraypheap K. Effect of molecular weights of chitosan coating on postharvest quality and physicochemical characteristics of mango fruit. LWT-Food Sci. Technol. 2016, 73, 28–36. 10.1016/j.lwt.2016.05.038. [DOI] [Google Scholar]

- Hassan B.; Chatha S. A. S.; Hussain A. I.; Zia K. M.; Akhtar N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2018, 109, 1095–1107. 10.1016/j.ijbiomac.2017.11.097. [DOI] [PubMed] [Google Scholar]

- Maringgal B.; Hashim N.; Mohamed Amin Tawakkal I. S.; Muda Mohamed M. T. Recent advance in edible coating and its effect on fresh/fresh-cut fruits quality. Trends Food Sci. Technol. 2020, 96, 253–267. 10.1016/j.tifs.2019.12.024. [DOI] [Google Scholar]

- Díaz-Montes E.; Castro-Muñoz R. Edible films and coatings as food-quality preservers: An overview. Foods 2021, 10 (2), 249. 10.3390/foods10020249. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Díaz-Montes E.; Castro-Muñoz R. Trends in chitosan as a primary biopolymer for functional films and coatings manufacture for food and natural products. Polymers 2021, 13 (5), 767. 10.3390/polym13050767. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Díaz-Montes E.; Yáñez-Fernández J.; Castro-Muñoz R. Dextran/chitosan blend film fabrication for bio-packaging of mushrooms (Agaricus bisporus). J. Food Process.Preserv. 2021, 45 (6), e15489 10.1111/jfpp.15489. [DOI] [Google Scholar]

- Díaz-Montes E.; Yáñez-Fernández J.; Castro-Muñoz R. Characterization of oligodextran produced by Leuconostoc mesenteroides SF3 and its effect on film-forming properties of chitosan. Mater. Today Commun. 2021, 28, 102487. 10.1016/j.mtcomm.2021.102487. [DOI] [Google Scholar]

- Sharma H. P.; Chaudhary V.; Kumar M. Importance of edible coating on fruits and vegetables: A review. J. Pharmacogn. Phytochem. 2019, 8 (3), 4104–4110. [Google Scholar]

- Guimaraẽs A.; Abrunhosa L.; Pastrana L. M.; Cerqueira M. A. Edible films and coatings as carriers of living microorganisms: A new strategy towards biopreservation and healthier foods. Compr. Rev. Food Sci. Food Saf. 2018, 17 (3), 594–614. 10.1111/1541-4337.12345. [DOI] [PubMed] [Google Scholar]

- Al-Tayyar N. A.; Youssef A. M.; Al-Hindi R. Antimicrobial food packaging based on sustainable Bio-based materials for reducing foodborne Pathogens: A review. Food Chem. 2020, 310, 125915. 10.1016/j.foodchem.2019.125915. [DOI] [PubMed] [Google Scholar]

- Hashemi S. M. B.; Jafarpour D. Bioactive edible film based on Konjac glucomannan and probiotic Lactobacillus plantarum strains: Physicochemical properties and shelf life of fresh-cut kiwis. J. Food Sci. 2021, 86 (2), 513–522. 10.1111/1750-3841.15568. [DOI] [PubMed] [Google Scholar]

- Vásconez M. B.; Flores S. K.; Campos C. A.; Alvarado J.; Gerschenson L. N. Antimicrobial activity and physical properties of chitosan-tapioca starch based edible films and coatings. Food Res. Int. 2009, 42 (7), 762–769. 10.1016/j.foodres.2009.02.026. [DOI] [Google Scholar]

- Aloui H.; Khwaldia K. Natural antimicrobial edible coatings for microbial safety and food quality enhancement. Compr. Rev. Food Sci. Food Saf. 2016, 15 (6), 1080–1103. 10.1111/1541-4337.12226. [DOI] [PubMed] [Google Scholar]

- Jeevahan J.; Chandrasekaran M. Nanoedible films for food packaging: A review. J. Mater. Sci. 2019, 54 (19), 12290–12318. 10.1007/s10853-019-03742-y. [DOI] [Google Scholar]

- Mkandawire M.; Aryee A. N. Resurfacing and modernization of edible packaging material technology. Curr. Opin. in Food Sci. 2018, 19, 104–112. 10.1016/j.cofs.2018.03.010. [DOI] [Google Scholar]

- Kaczmarek B. Tannic acid with antiviral and antibacterial activity as a promising component of biomaterials—A minireview. Materials 2020, 13 (14), 3224. 10.3390/ma13143224. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee S. J.; Gwak M. A.; Chathuranga K.; Lee J. S.; Koo J.; Park W. H. Multifunctional chitosan/tannic acid composite films with improved anti-UV, antioxidant, and antimicrobial properties for active food packaging. Food Hydrocoll. 2023, 136, 108249. 10.1016/j.foodhyd.2022.108249. [DOI] [Google Scholar]

- Kaczmarek B.; Owczarek A.; Nadolna K.; Sionkowska A. The film-forming properties of chitosan with tannic acid addition. Mater. Lett. 2019, 245, 22–24. 10.1016/j.matlet.2019.02.090. [DOI] [Google Scholar]

- Wang Y.; Xiong Y. L. Physicochemical and microstructural characterization of whey protein films formed with oxidized ferulic/tannic acids. Foods 2021, 10 (7), 1599. 10.3390/foods10071599. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhao S.; Jia R.; Yang J.; Dai L.; Ji N.; Xiong L.; Sun Q. Development of chitosan/tannic acid/corn starch multifunctional bilayer smart films as pH-responsive actuators and for fruit preservation. Int. J. Biol. Macromol. 2022, 205, 419–429. 10.1016/j.ijbiomac.2022.02.101. [DOI] [PubMed] [Google Scholar]

- Zhang W.; Roy S.; Ezati P.; Yang D.-P.; Rhim J. W. Tannic acid: A green crosslinker for biopolymer-based food packaging films. Trend. Food Sci. Technol. 2023, 136, 11–23. 10.1016/j.tifs.2023.04.004. [DOI] [Google Scholar]

- Luangapai F.; Peanparkdee M.; Iwamoto S. Biopolymer films for food industries: Properties, applications, and future aspects based on chitosan. Rev. Agric. Sci. 2019, 7, 59–67. 10.7831/ras.7.0_59. [DOI] [Google Scholar]

- Calva-Estrada S. J.; Jiménez-Fernández M.; Lugo-Cervantes E. Protein-based films: Advances in the development of biomaterials applicable to food packaging. Food Eng. Rev. 2019, 11, 78–92. 10.1007/s12393-019-09189-w. [DOI] [Google Scholar]

- Gallego M. G.; Gordon M. H.; Segovia F.; Almajano Pablos M. P. Gelatine-based antioxidant packaging containing Caesalpinia decapetala and Tara as a coating for ground beef patties. Antioxidants 2016, 5 (2), 10. 10.3390/antiox5020010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alkan D.; Yemenicioǧlu A. Potential application of natural phenolic antimicrobials and edible film technology against bacterial plant pathogens. Food Hydrocoll. 2016, 55, 1–10. 10.1016/j.foodhyd.2015.10.025. [DOI] [Google Scholar]

- Kumar V. A.; Hasan M.; Mangaraj S.; Pravitha M.; Verma D. K.; Srivastav P. P. Trends in edible packaging films and its prospective future in food: a review. Appl. Food Res. 2022, 2 (1), 100118. 10.1016/j.afres.2022.100118. [DOI] [Google Scholar]

- Fernandes L. M.; Guimarães J. T.; Pimentel T. C.; Esmerino E. A.; Freitas M. Q.; Carvalho C. W. P.; Cruz A. G.; Silva M. C.. Edible whey protein films and coatings added with prebiotic ingredients. In Agri-food industry strategies for healthy diets and sustainability; Elsevier, 2020; pp 177–193. [Google Scholar]

- Garavand F.; Jafarzadeh S.; Cacciotti I.; Vahedikia N.; Sarlak Z.; Tarhan O.; Yousefi S.; Rouhi M.; Castro-Munoz R.; Jafari S. M. Different strategies to reinforce the milk protein-based packaging composites. Trend. Food Sci. Technol. 2022, 123, 1–14. 10.1016/j.tifs.2022.03.004. [DOI] [Google Scholar]

- Pérez-Guzmán C. J.; Castro-Muñoz R. A review of zein as a potential biopolymer for tissue engineering and nanotechnological applications. Processes 2020, 8 (11), 1376. 10.3390/pr8111376. [DOI] [Google Scholar]

- Fabra M. J.; Falcó I.; Randazzo W.; Sánchez G.; López-Rubio A. Antiviral and antioxidant properties of active alginate edible films containing phenolic extracts. Food Hydrocoll. 2018, 81, 96–103. 10.1016/j.foodhyd.2018.02.026. [DOI] [Google Scholar]

- Estevinho B. M. A. N.; Rocha F. A. N.; Santos L. M. D. S.; Alves M. A. C. Using water-soluble chitosan for flavour microencapsulation in food industry. J. Microencap. 2013, 30 (6), 571–579. 10.3109/02652048.2013.764939. [DOI] [PubMed] [Google Scholar]

- Ganiari S.; Choulitoudi E.; Oreopoulou V. Edible and active films and coatings as carriers of natural antioxidants for lipid food. Trend. Food Sci. Technol. 2017, 68, 70–82. 10.1016/j.tifs.2017.08.009. [DOI] [Google Scholar]

- Alotaibi M. A.; Tayel A. A.; Zidan N. S.; El Rabey H. A. Bioactive coatings from nano-biopolymers/plant extract composites for complete protection from mycotoxigenic fungi in dates. J. Sci. Food Agric. 2019, 99 (9), 4338–4343. 10.1002/jsfa.9667. [DOI] [PubMed] [Google Scholar]

- Khalifa I.; Barakat H.; El-Mansy H. A.; Soliman S. A. Improving the shelf-life stability of apple and strawberry fruits applying chitosan-incorporated olive oil processing residues coating. Food Pack. Shelf Life 2016, 9, 10–19. 10.1016/j.fpsl.2016.05.006. [DOI] [Google Scholar]

- Rangel-Marrón M.; Mani-López E.; Palou E.; López-Malo A. Effects of alginate-glycerol-citric acid concentrations on selected physical, mechanical, and barrier properties of papaya puree-based edible films and coatings, as evaluated by response surface methodology. LWT-Food Sci. Technol. 2019, 101, 83–91. 10.1016/j.lwt.2018.11.005. [DOI] [Google Scholar]

- Cofelice M.; Lopez F.; Cuomo F. Quality control of fresh-cut apples after coating application. Foods 2019, 8 (6), 189. 10.3390/foods8060189. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gonçalves A.; Estevinho B. N.; Rocha F. Design and characterization of controlled-release vitamin A microparticles prepared by a spray-drying process. Powder Technol. 2017, 305, 411–417. 10.1016/j.powtec.2016.10.010. [DOI] [Google Scholar]

- Tomadoni B.; Moreira M. d. R.; Pereda M.; Ponce A. G. Gellan-based coatings incorporated with natural antimicrobials in fresh-cut strawberries: Microbiological and sensory evaluation through refrigerated storage. LWT-Food Sci. Technol. 2018, 97, 384–389. 10.1016/j.lwt.2018.07.029. [DOI] [Google Scholar]

- Punia S.; Sandhu K. S.; Dhull S. B.; Kaur M. Dynamic, shear and pasting behaviour of native and octenyl succinic anhydride (OSA) modified wheat starch and their utilization in preparation of edible films. Int. J. Biol. Macromol. 2019, 133, 110–116. 10.1016/j.ijbiomac.2019.04.089. [DOI] [PubMed] [Google Scholar]

- Tóth A.; Halász K. Characterization of edible biocomposite films directly prepared from psyllium seed husk and husk flour. Food Pack. Shelf Life 2019, 20, 100299. 10.1016/j.fpsl.2019.01.003. [DOI] [Google Scholar]

- Alves A. C. R. S.; Lima A. M. F.; Tiera M. J.; Aparecida de Oliveira Tiera V. Biopolymeric films of amphiphilic derivatives of chitosan: a physicochemical characterization and antifungal study. Int. J. Mol. Sci. 2019, 20 (17), 4173. 10.3390/ijms20174173. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chi H.; Song S.; Luo M.; Zhang C.; Li W.; Li L.; Qin Y. Effect of PLA nanocomposite films containing bergamot essential oil, TiO2 nanoparticles, and Ag nanoparticles on shelf life of mangoes. Sci. Hortic. 2019, 249, 192–198. 10.1016/j.scienta.2019.01.059. [DOI] [Google Scholar]

- Emamifar A.; Bavaisi S. Nanocomposite coating based on sodium alginate and nano-ZnO for extending the storage life of fresh strawberries (Fragaria× ananassa Duch.). J. Food Meas. Charact. 2020, 14 (2), 1012–1024. 10.1007/s11694-019-00350-x. [DOI] [Google Scholar]

- Silva M. R. J.; Cordeiro J. M. M.; Silva B. E. C.; Segunda M. N.; Maia F. Caracterização do sistema de produção de leite no projeto aldeia nova do waku-kungo. Revista Ifes Ciência 2019, 5 (2), 217–229. 10.36524/ric.v5i2.459. [DOI] [Google Scholar]

- Kaewklin P.; Siripatrawan U.; Suwanagul A.; Lee Y. S. Active packaging from chitosan-titanium dioxide nanocomposite film for prolonging storage life of tomato fruit. Int. J. Biol. Macromol. 2018, 112, 523–529. 10.1016/j.ijbiomac.2018.01.124. [DOI] [PubMed] [Google Scholar]

- Jafarzadeh S.; Mohammadi Nafchi A.; Salehabadi A.; Oladzad-abbasabadi N.; Jafari S. M. Application of bio-nanocomposite films and edible coatings for extending the shelf life of fresh fruits and vegetables. Adv. Colloid Interface Sci. 2021, 291, 102405. 10.1016/j.cis.2021.102405. [DOI] [PubMed] [Google Scholar]

- Salas-Mendez E. d. J.; Vicente A.; Pinheiro A. C.; Ballesteros L. F.; Silva P.; Rodriguez-Garcia R.; Hernandez-Castillo F. D.; Diaz-Jimenez M. d. L. V.; Flores-Lopez M. L.; Villarreal-Quintanilla J. A.; Pena-Ramos F. M.; Carrillo-Lomeli D. A.; Jasso de Rodriguez D. Application of edible nanolaminate coatings with antimicrobial extract of Flourensia cernua to extend the shelf-life of tomato (Solanum lycopersicum L.) fruit. Postharvest Biol. Technol. 2019, 150, 19–27. 10.1016/j.postharvbio.2018.12.008. [DOI] [Google Scholar]

- El Hosry L.; Auezova L.; Sakr A.; Hajj-Moussa E. Browning susceptibility of white wine and antioxidant effect of glutathione. Int. J. Food Sci. Technol. 2009, 44 (12), 2459–2463. 10.1111/j.1365-2621.2009.02036.x. [DOI] [Google Scholar]

- Falguera V.; Quintero J. P.; Jimenez A.; Munoz J. A.; Ibarz A. Edible films and coatings: Structures, active functions and trends in their use. Trend Food Sci. Technol. 2011, 22, 292–303. 10.1016/j.tifs.2011.02.004. [DOI] [Google Scholar]

- Tapia-Blácido D.; Sobral P. J.; Menegalli F. C. Development and characterization of biofilms based on Amaranth flour (Amaranthus caudatus). J. Food Eng. 2005, 67 (1–2), 215–223. 10.1016/j.jfoodeng.2004.05.054. [DOI] [Google Scholar]

- Araujo-Farro P. C.; Podadera G.; Sobral P. J.; Menegalli F. C. Development of films based on quinoa (Chenopodium quinoa, Willdenow) starch. Carbohydr. Polym. 2010, 81 (4), 839–848. 10.1016/j.carbpol.2010.03.051. [DOI] [Google Scholar]

- Dick M.; Henrique Pagno C.; Haas Costa T. M.; Gomaa A.; Subirade M.; de Oliveira Rios A.; Hickmann Flôres S. Edible films based on chia flour: Development and characterization. J. Appl. Polym. Sci. 2016, 133 (2), 1. 10.1002/app.42455. [DOI] [Google Scholar]

- Nouraddini M.; Esmaiili M.; Mohtarami F. Development and characterization of edible films based on eggplant flour and corn starch. Int. J. Biol. Macromol. 2018, 120, 1639–1645. 10.1016/j.ijbiomac.2018.09.126. [DOI] [PubMed] [Google Scholar]

- Aydogdu A.; Kirtil E.; Sumnu G.; Oztop M. H.; Aydogdu Y. Utilization of lentil flour as a biopolymer source for the development of edible films. J. Appl. Polym. Sci. 2018, 135 (23), 46356. 10.1002/app.46356. [DOI] [Google Scholar]

- Diaz O.; Ferreiro T.; Rodriguez-Otero J.; Cobos A. Characterization of chickpea (Cicer arietinum L.) flour films: Effects of pH and plasticizer concentration. Int. J. Mol. Sci. 2019, 20 (5), 1246. 10.3390/ijms20051246. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bourtoom T. Factors affecting the properties of edible film prepared from mung bean proteins. Int. Food Res. J. 2008, 15 (2), 167–180. [Google Scholar]

- Ochoa-Yepes O.; Medina-Jaramillo C.; Guz L.; Famá L. Biodegradable and edible starch composites with fiber-rich lentil flour to use as food packaging. Starch-Stärke 2018, 70 (7–8), 1700222. 10.1002/star.201700222. [DOI] [Google Scholar]

- Pelissari F. M.; Andrade-Mahecha M. M.; Sobral P. J. d. A.; Menegalli F. C. Comparative study on the properties of flour and starch films of plantain bananas (Musa paradisiaca). Food Hydrocoll. 2013, 30 (2), 681–690. 10.1016/j.foodhyd.2012.08.007. [DOI] [Google Scholar]

- Roberta M.; Mariana S.; Édira C. Functional capacity of flour obtained from residues of fruit and vegetables. Int. Food Res. J. 2014, 21 (4), 1675–1681. [Google Scholar]

- Ahmad M. M.; Chatha S. A. S.; Hussain A. I.; Khan I. Chemical modification and antioxidant activities of Carissa carandas fruit polysaccharides. J. Food Measur. Character. 2023, 17 (2), 1175–1185. 10.1007/s11694-022-01693-8. [DOI] [Google Scholar]

- Andrade R. M.; Ferreira M. S.; Gonçalves É. C. Development and characterization of edible films based on fruit and vegetable residues. J. Food Sci. 2016, 81 (2), E412–E418. 10.1111/1750-3841.13192. [DOI] [PubMed] [Google Scholar]

- Brito T.; Carrajola J.; Gonçalves E.; Martelli-Tosi M.; Ferreira M. Fruit and vegetable residues flours with different granulometry range as raw material for pectin-enriched biodegradable film preparation. Food Res. Int. 2019, 121, 412–421. 10.1016/j.foodres.2019.03.058. [DOI] [PubMed] [Google Scholar]

- Ahmad M. M.; Chatha S. A. S.; Iqbal Y.; Hussain A. I.; Khan I.; Xie F. Recent trends in extraction, purification, and antioxidant activity evaluation of plant leaf-extract polysaccharides. Biofuels, Bioprod. Biorefining 2022, 16 (6), 1820–1848. 10.1002/bbb.2405. [DOI] [Google Scholar]

- Himanshu D. D. S.; Bhavani M. Polysaccharide, protein, lipid-based coatings and their impact on fruit crops. Pharma Innov. J. 2023, 12 (3), 3314–3323. [Google Scholar]

- Du Y.; Zhao Y.; Dai S.; Yang B. Preparation of water-soluble chitosan from shrimp shell and its antibacterial activity. Innov. Food Sci. Emerg. Technol. 2009, 10 (1), 103–107. 10.1016/j.ifset.2008.07.004. [DOI] [Google Scholar]

- Šuput D. Z.; Lazić V. L.; Popović S. Z.; Hromiš N. M. Edible films and coatings: Sources, properties and application. Food Feed Res. 2015, 42 (1), 11–22. 10.5937/FFR1501011S. [DOI] [Google Scholar]

- Kontogiorgos V.Pectin: Technological and Physiological properties. Springer: Cham, 2020, 10.1007/978-3-030-53421-9. [DOI] [Google Scholar]

- Cabezas R.; Zurob E.; Gomez B.; Merlet G.; Plaza A.; Araya-Lopez C.; Romero J.; Olea F.; Quijada-Maldonado E.; Pino-Soto L.; Gonzalez T.; Castro-Munoz R. Challenges and possibilities of deep eutectic solvent-based membranes. Ind. Eng. Chem. Res. 2022, 61 (48), 17397–17422. 10.1021/acs.iecr.2c02747. [DOI] [Google Scholar]

- Asim M.; Nazir M.; Chauhdary Z.; Irfan M.; Khalid S. H.; Asghar S.; Usra; Felimban R. I.; Majrashi M. A.; Hazzazi M. S.; Alissa M.; Qahl S. H.; Hussain G.; Rasul A.; Chatha S. A. S.; Khan I. U. Enhanced Solubility and Biological Activity of Dexibuprofen-Loaded Silica-Based Ternary Solid Dispersions. Pharmaceutics 2023, 15 (2), 399. 10.3390/pharmaceutics15020399. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li H.; Liu C.; Sun J.; Lv S. Bioactive Edible Sodium Alginate Films Incorporated with Tannic Acid as Antimicrobial and Antioxidative Food Packaging. Foods 2022, 11 (19), 3044. 10.3390/foods11193044. [DOI] [PMC free article] [PubMed] [Google Scholar]

- van Nieuwenhuyzen W.; Szuhaj B. F. Effects of lecithins and proteins on the stability of emulsions. Lipid/Fett 1998, 100 (7), 282–291. . [DOI] [Google Scholar]

- Jiang J.; Yu S.; Zhang W.; Zhang H.; Cui Z.; Xia W.; Binks B. P. Charge-reversible surfactant-induced transformation between oil-in-dispersion emulsions and pickering emulsions. Angew. Chem., Int. Ed. 2021, 60 (21), 11793–11798. 10.1002/anie.202102098. [DOI] [PubMed] [Google Scholar]

- Moreno M. A.; Orqueda M. E.; Gómez-Mascaraque L. G.; Isla M. I.; López-Rubio A. Crosslinked electrospun zein-based food packaging coatings containing bioactive chilto fruit extracts. Food Hydrocoll. 2019, 95, 496–505. 10.1016/j.foodhyd.2019.05.001. [DOI] [Google Scholar]

- Han J.; Bourgeois S.; Lacroix M. Protein-based coatings on peanut to minimise oil migration. Food Chem. 2009, 115 (2), 462–468. 10.1016/j.foodchem.2008.12.030. [DOI] [Google Scholar]

- Castro-Munoz R.; Buera-Gonzalez J.; Iglesia O. d. l.; Galiano F.; Fila V.; Malankowska M.; Rubio C.; Figoli A.; Tellez C.; Coronas J. Towards the dehydration of ethanol using pervaporation cross-linked poly (vinyl alcohol)/graphene oxide membranes. J. Membr. Sci. 2019, 582, 423–434. 10.1016/j.memsci.2019.03.076. [DOI] [Google Scholar]

- Andrade R. D.; Skurtys O.; Osorio F. A. Atomizing spray systems for application of edible coatings. Compr. Rev. Food Sci. Food Saf. 2012, 11 (3), 323–337. 10.1111/j.1541-4337.2012.00186.x. [DOI] [Google Scholar]

- Van Hung P.; Morita N. Physicochemical properties and enzymatic digestibility of starch from edible canna (Canna edulis) grown in Vietnam. Carbohydr. Polym. 2005, 61 (3), 314–321. 10.1016/j.carbpol.2005.04.021. [DOI] [Google Scholar]

- Galindez A.; Daza L. D.; Homez-Jara A.; Eim V. S.; Váquiro H. A. Characterization of ulluco starch and its potential for use in edible films prepared at low drying temperature. Carbohydr. Polym. 2019, 215, 143–150. 10.1016/j.carbpol.2019.03.074. [DOI] [PubMed] [Google Scholar]

- Bae H. J.; Cha D. S.; Whiteside W. S.; Park H. J. Film and pharmaceutical hard capsule formation properties of mungbean, waterchestnut, and sweet potato starches. Food Chem. 2008, 106 (1), 96–105. 10.1016/j.foodchem.2007.05.070. [DOI] [Google Scholar]

- Patel S.; Goyal A. Applications of natural polymer gum arabic: a review. Int. J. Food Prop. 2015, 18 (5), 986–998. 10.1080/10942912.2013.809541. [DOI] [Google Scholar]

- Mahfoudhi N.; Hamdi S. Use of almond gum and gum arabic as novel edible coating to delay postharvest ripening and to maintain sweet cherry (Prunus avium) quality during storage. J. Food Process. Preser. 2015, 39 (6), 1499–1508. 10.1111/jfpp.12369. [DOI] [Google Scholar]

- Ali A.; Maqbool M.; Ramachandran S.; Alderson P. G. Gum arabic as a novel edible coating for enhancing shelf-life and improving postharvest quality of tomato (Solanum lycopersicum L.) fruit. Postharvest Biol. Technol. 2010, 58 (1), 42–47. 10.1016/j.postharvbio.2010.05.005. [DOI] [Google Scholar]

- El-Anany A.; Hassan G.; Ali F. R. Effects of edible coatings on the shelf-life and quality of Anna apple (Malus domestica Borkh) during cold storage. J. Food Technol. 2009, 7 (1), 5–11. [Google Scholar]

- Tahir H. E.; Xiaobo Z.; Jiyong S.; Mahunu G. K.; Zhai X.; Mariod A. A. Quality and postharvest-shelf life of cold-stored strawberry fruit as affected by gum arabic (Acacia senegal) edible coating. J. Food Biochem. 2018, 42 (3), e12527 10.1111/jfbc.12527. [DOI] [Google Scholar]

- Robles-Flores G. d. C.; Abud-Archila M.; Ventura-Canseco L. M. C.; Meza-Gordillo R.; Grajales-Lagunes A.; Ruiz-Cabrera M. A.; Gutiérrez-Miceli F. A. Development and evaluation of a film and edible coating obtained from the Cajanus cajan seed applied to fresh strawberry fruit. Food Bioprocess Technol. 2018, 11, 2172–2181. 10.1007/s11947-018-2175-5. [DOI] [Google Scholar]

- Riaz S.; Tauseef Sultan M.; Sibt-e-Abass M.; Imran M.; Shabir Ahmad R.; Bilal Hussain M.; Ali Shariati M.; Sergeevna Kosenko I.; Leonidovna Kleymenova N.; Nikolaevna Egorova G. Extraction of polysaccharides from opuntia cactus for its potential application in edible coating to improve the shelf life of citrus (Kinnow mandarin) fruit. J. Microbiol. Biotechnol. Food Sci. 2018, 8 (1), 745–750. 10.15414/jmbfs.2018.8.1.745-750. [DOI] [Google Scholar]

- Oliveira N. L.; Rodrigues A. A.; Oliveira Neves I. C.; Teixeira Lago A. M.; Borges S. V.; de Resende J. V. Development and characterization of biodegradable films based on Pereskia aculeata Miller mucilage. Ind. Crop Prod. 2019, 130, 499–510. 10.1016/j.indcrop.2019.01.014. [DOI] [Google Scholar]

- Behbahani B. A.; Imani Fooladi A. A. Shirazi balangu (Lallemantia royleana) seed mucilage: Chemical composition, molecular weight, biological activity and its evaluation as edible coating on beefs. Int. J. Biol. Macromol. 2018, 114, 882–889. 10.1016/j.ijbiomac.2018.03.177. [DOI] [PubMed] [Google Scholar]

- Kim S. Y.; Kang J. H.; Jo J. H.; Min S. C. Development of a Gulfweed-Based Edible Coating Using High-Pressure Homogenization and Its Application to Smoked Salmon. J. Food Sci. 2018, 83 (12), 3027–3034. 10.1111/1750-3841.14395. [DOI] [PubMed] [Google Scholar]

- Khajavian M.; Vatanpour V.; Castro-Muñoz R.; Boczkaj G. Chitin and derivative chitosan-based structures—Preparation strategies aided by deep eutectic solvents: A review. Carbohydr. Polym. 2022, 275, 118702. 10.1016/j.carbpol.2021.118702. [DOI] [PubMed] [Google Scholar]

- Castro-Muñoz R.; Msahel A.; Galiano F.; Serocki M.; Ryl J.; Hamouda S. B.; Hafiane A.; Boczkaj G.; Figoli A. Towards azeotropic MeOH-MTBE separation using pervaporation chitosan-based deep eutectic solvent membranes. Sep. Purif. Technol. 2022, 281, 119979. 10.1016/j.seppur.2021.119979. [DOI] [Google Scholar]

- Castro-Muñoz R.; Gontarek-Castro E.; Karczewski J.; Cabezas R.; Merlet G.; Araya-Lopez C.; Boczkaj G. Hybrid cross-linked chitosan/protonated-proline: glucose DES membranes with superior pervaporation performance for ethanol dehydration. J. Mol. Liq. 2022, 360, 119499. 10.1016/j.molliq.2022.119499. [DOI] [Google Scholar]

- Kraśniewska K.; Galus S.; Gniewosz M. Biopolymers-based materials containing silver nanoparticles as active packaging for food applications-a review. Int. J. Mol. Sci. 2020, 21 (3), 698. 10.3390/ijms21030698. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Costa M. J.; Maciel L. C.; Teixeira J. A.; Vicente A. A.; Cerqueira M. A. Use of edible films and coatings in cheese preservation: Opportunities and challenges. Food Res. Int. 2018, 107, 84–92. 10.1016/j.foodres.2018.02.013. [DOI] [PubMed] [Google Scholar]

- Kurek M.; Scetar M.; Galic K. Edible coatings minimize fat uptake in deep fat fried products: A review. Food Hydrocoll. 2017, 71, 225–235. 10.1016/j.foodhyd.2017.05.006. [DOI] [Google Scholar]

- Ju J.; Xie Y.; Guo Y.; Cheng Y.; Qian H.; Yao W. Application of edible coating with essential oil in food preservation. Crit. Rev. Food Sci. Nutr. 2019, 59 (15), 2467–2480. 10.1080/10408398.2018.1456402. [DOI] [PubMed] [Google Scholar]

- Ribeiro-Santos R.; Andrade M.; Melo N. R. d.; Sanches-Silva A. Use of essential oils in active food packaging: Recent advances and future trends. Trend Food Sci. Technol. 2017, 61, 132–140. 10.1016/j.tifs.2016.11.021. [DOI] [Google Scholar]

- Ackermann P.; Jägerstad M.; Ohlsson T.. Foods and Packaging Materials: Chemical Interactions: the Proceedings of an International Symposium on Interaction: Foods-Food Packaging Materials, Lund, Sweden, June 8–10, 1994; Royal Society of Chemistry, 1995.

- Franssen L.; Krochta J. Edible coatings containing natural antimicrobials for processed foods. Natural Antimicrobials for the Minimal Processing of Foods 2003, 250–262. 10.1533/9781855737037.250. [DOI] [Google Scholar]

- Wan V. C. H.; Lee C. M.; Lee S. Y. Understanding consumer attitudes on edible films and coatings: Focus group findings. J. Sens. Stud. 2007, 22 (3), 353–366. 10.1111/j.1745-459X.2007.00108.x. [DOI] [Google Scholar]

- Krasniewska K.; Gniewosz M. Substances with antibacterial activity in edible films-a review. Polym. J. Food Nutr. Sci. 2012, 62 (4), 199. 10.2478/v10222-12-0059-3. [DOI] [Google Scholar]

- Maan A. A.; Reiad Ahmed Z. F.; Iqbal Khan M. K.; Riaz A.; Nazir A. Aloe vera gel, an excellent base material for edible films and coatings. Trend Food Sci. Technol. 2021, 116, 329–341. 10.1016/j.tifs.2021.07.035. [DOI] [Google Scholar]

- Arroyo B. J.; Bezerra A. C.; Oliveira L. L.; Arroyo S. J.; Melo E. A. d.; Santos A. M. P. Antimicrobial active edible coating of alginate and chitosan add ZnO nanoparticles applied in guavas (Psidium guajava L.). Food Chem. 2020, 309, 125566. 10.1016/j.foodchem.2019.125566. [DOI] [PubMed] [Google Scholar]

- Al-Tayyar N. A.; Youssef A. M.; Al-Hindi R. R. Edible coatings and antimicrobial nanoemulsions for enhancing shelf life and reducing foodborne pathogens of fruits and vegetables: A review. Sustain. Mater. Technol. 2020, 26, e00215 10.1016/j.susmat.2020.e00215. [DOI] [Google Scholar]

- Contreras Saavedra S.; Isela Ventura-Aguilar R.; Bautista-Banos S.; Barrera-Necha L. L. Biodegradable chitosan coating for improving quality and controlling Alternaria alternata growth in figs. World J. Adv. Res. Rev. 2020, 7 (2), 115–125. 10.30574/wjarr.2020.7.2.0246. [DOI] [Google Scholar]

- Hernández-López G.; Ventura-Aguilar R. I.; Correa-Pacheco Z. N.; Bautista-Baños S.; Barrera-Necha L. L. Nanostructured chitosan edible coating loaded with α-pinene for the preservation of the postharvest quality of Capsicum annuum L. and Alternaria alternata control. Int. J. Biol. Macromol. 2020, 165, 1881–1888. 10.1016/j.ijbiomac.2020.10.094. [DOI] [PubMed] [Google Scholar]

- Liguori G.; Gaglio R.; Greco G.; Gentile C.; Settanni L.; Inglese P. Effect of Opuntia ficus-indica mucilage edible coating on quality, nutraceutical, and sensorial parameters of minimally processed cactus pear fruits. Agronomy 2021, 11 (10), 1963. 10.3390/agronomy11101963. [DOI] [Google Scholar]

- Alvarez M. V.; Ponce A. G.; Moreira M. R. Influence of polysaccharide-based edible coatings as carriers of prebiotic fibers on quality attributes of ready-to-eat fresh blueberries. J. Sci. Food Agric. 2018, 98 (7), 2587–2597. 10.1002/jsfa.8751. [DOI] [PubMed] [Google Scholar]

- Vargas-Torres A.; Becerra-Loza A. S.; Sayago-Ayerdi S. G.; Palma-Rodriguez H. M.; Garcia-Magana M. d. L.; Montalvo-Gonzalez E. Combined effect of the application of 1-MCP and different edible coatings on the fruit quality of jackfruit bulbs (Artocarpus heterophyllus Lam) during cold storage. Sci. Hortic. 2017, 214, 221–227. 10.1016/j.scienta.2016.11.045. [DOI] [Google Scholar]

- Azarakhsh N.; Osman A.; Ghazali H. M.; Tan C. P.; Mohd Adzahan N. Lemongrass essential oil incorporated into alginate-based edible coating for shelf-life extension and quality retention of fresh-cut pineapple. Postharvest Biol. Technol. 2014, 88, 1–7. 10.1016/j.postharvbio.2013.09.004. [DOI] [Google Scholar]

- Azevedo V. M.; Dias M. V.; de Siqueira Elias H. H.; Fukushima K. L.; Silva E. K.; de Deus Souza Carneiro J.; de Fatima Ferreira Soares N.; Borges S. V. Effect of whey protein isolate films incorporated with montmorillonite and citric acid on the preservation of fresh-cut apples. Food Res. Int. 2018, 107, 306–313. 10.1016/j.foodres.2018.02.050. [DOI] [PubMed] [Google Scholar]

- Licciardello F.; Lombardo S.; Rizzo V.; Pitino I.; Pandino G.; Strano M. G.; Muratore G.; Restuccia C.; Mauromicale G. Integrated agronomical and technological approach for the quality maintenance of ready-to-fry potato sticks during refrigerated storage. Postharvest Biol. Technol. 2018, 136, 23–30. 10.1016/j.postharvbio.2017.10.001. [DOI] [Google Scholar]

- Sipahi R.; Castell-Perez M.; Moreira R.; Gomes C.; Castillo A. Improved multilayered antimicrobial alginate-based edible coating extends the shelf life of fresh-cut watermelon (Citrullus lanatus). LWT-Food Sci. Technol. 2013, 51 (1), 9–15. 10.1016/j.lwt.2012.11.013. [DOI] [Google Scholar]

- Robles-Sánchez R. M.; Rojas-Graü M. A.; Odriozola-Serrano I.; González-Aguilar G.; Martin-Belloso O. Influence of alginate-based edible coating as carrier of antibrowning agents on bioactive compounds and antioxidant activity in fresh-cut Kent mangoes. LWT-Food Sci. Technol. 2013, 50 (1), 240–246. 10.1016/j.lwt.2012.05.021. [DOI] [Google Scholar]

- Jafari S. M.; Bahrami I.; Dehnad D.; Shahidi S. A. The influence of nanocellulose coating on saffron quality during storage. Carbohydr. Polym. 2018, 181, 536–542. 10.1016/j.carbpol.2017.12.008. [DOI] [PubMed] [Google Scholar]

- Aly S. S. H.; Enstar N. M.; Enstar S. A. Effect of edible coating on extending the shelf life and quality of fresh cut taro. Am. J. Food Technol. 2017, 12, 124–131. 10.3923/ajft.2017.124.131. [DOI] [Google Scholar]

- Fagundes C.; Palou L.; Monteiro A. R.; Pérez-Gago M. B. Hydroxypropyl methylcellulose-beeswax edible coatings formulated with antifungal food additives to reduce alternaria black spot and maintain postharvest quality of cold-stored cherry tomatoes. Sci. Hortic. 2015, 193, 249–257. 10.1016/j.scienta.2015.07.027. [DOI] [Google Scholar]

- Jiang T.; Feng L.; Wang Y. Effect of alginate/nano-Ag coating on microbial and physicochemical characteristics of shiitake mushroom (Lentinus edodes) during cold storage. Food Chem. 2013, 141 (2), 954–960. 10.1016/j.foodchem.2013.03.093. [DOI] [PubMed] [Google Scholar]

- Rhim J.-W.; Wang L.-F. Mechanical and water barrier properties of agar/κ-carrageenan/konjac glucomannan ternary blend biohydrogel films. Carbohydr. Polym. 2013, 96 (1), 71–81. 10.1016/j.carbpol.2013.03.083. [DOI] [PubMed] [Google Scholar]

- Tzoumaki M. V.; Biliaderis C. G.; Vasilakakis M. Impact of edible coatings and packaging on quality of white asparagus (Asparagus officinalis, L.) during cold storage. Food Chem. 2009, 117 (1), 55–63. 10.1016/j.foodchem.2009.03.076. [DOI] [Google Scholar]

- Kalem I. K.; Bhat Z.; Kumar S.; Noor S.; Desai A. The effects of bioactive edible film containing Terminalia arjuna on the stability of some quality attributes of chevon sausages. Meat Sci. 2018, 140, 38–43. 10.1016/j.meatsci.2018.02.011. [DOI] [PubMed] [Google Scholar]

- Moura L. E.; de Souza C. O.; de Oliveira E. A. S.; Lemos P. V. F.; Druzian J. I. Bioactive efficacy of low-density polyethylene films with natural additives. J. Appl. Polym. Sci. 2018, 135 (34), 46461. 10.1002/app.46461. [DOI] [Google Scholar]

- Chakravartula S. S. N.; Cevoli C.; Balestra F.; Fabbri A.; Dalla Rosa M. Evaluation of drying of edible coating on bread using NIR spectroscopy. J. Food Eng. 2019, 240, 29–37. 10.1016/j.jfoodeng.2018.07.009. [DOI] [Google Scholar]

- Ahmed J.; Mulla M.; Arfat Y. A.; Bher A.; Jacob H.; Auras R. Compression molded LLDPE films loaded with bimetallic (Ag-Cu) nanoparticles and cinnamon essential oil for chicken meat packaging applications. LWT-Food Sci.Technol. 2018, 93, 329–338. 10.1016/j.lwt.2018.03.051. [DOI] [Google Scholar]

- Muppalla S. R.; Chawla S. Effect of Gum Arabic-polyvinyl alcohol films containing seed cover extract of Zanthoxylum rhetsa on shelf life of refrigerated ground chicken meat. J. Food Saf. 2018, 38 (4), e12460 10.1111/jfs.12460. [DOI] [Google Scholar]

- Zhao Y.; Teixeira J. S.; Gänzle M. M.; Saldaña M. D. Development of antimicrobial films based on cassava starch, chitosan and gallic acid using subcritical water technology. J. Supercrit. Fluid 2018, 137, 101–110. 10.1016/j.supflu.2018.03.010. [DOI] [Google Scholar]

- Albert A.; Salvador A.; Fiszman S. A film of alginate plus salt as an edible susceptor in microwaveable food. Food Hydrocoll. 2012, 27 (2), 421–426. 10.1016/j.foodhyd.2011.11.005. [DOI] [Google Scholar]

- Olaimat A. N.; Fang Y.; Holley R. A. Inhibition of Campylobacter jejuni on fresh chicken breasts by κ-carrageenan/chitosan-based coatings containing allyl isothiocyanate or deodorized oriental mustard extract. Int. J. Food Microbiol. 2014, 187, 77–82. 10.1016/j.ijfoodmicro.2014.07.003. [DOI] [PubMed] [Google Scholar]

- Cerqueira M. A.; Sousa-Gallagher M. J.; Macedo I.; Rodriguez-Aguilera R.; Souza B. W.; Teixeira J. A.; Vicente A. A. Use of galactomannan edible coating application and storage temperature for prolonging shelf-life of “Regional” cheese. J. Food Eng. 2010, 97 (1), 87–94. 10.1016/j.jfoodeng.2009.09.019. [DOI] [Google Scholar]

- Song Y.; Liu L.; Shen H.; You J.; Luo Y. Effect of sodium alginate-based edible coating containing different anti-oxidants on quality and shelf life of refrigerated bream (Megalobrama amblycephala). Food Control 2011, 22 (3–4), 608–615. 10.1016/j.foodcont.2010.10.012. [DOI] [Google Scholar]

- Juck G.; Neetoo H.; Chen H. Application of an active alginate coating to control the growth of Listeria monocytogenes on poached and deli turkey products. Int. J. Food Microbiol. 2010, 142 (3), 302–308. 10.1016/j.ijfoodmicro.2010.07.006. [DOI] [PubMed] [Google Scholar]