Abstract

The current work focused on the effect of repetitive frying on the physicochemical characteristics of palm oil (PO)and sesame oil (SO) during the preparation of french fries by deep fat frying. A total of 16 frying cycles were carried out and the effect on various parameters was evaluated. The repetitive frying caused higher damage to sesame oil as compared with PO as observed from changes in FFA and PV which increased to 0.63 ± 0.12, 1.31 ± 0.16%, and 2.71 ± 0.02, 7.21 ± 0.01 meq/kg from an initial value of 0.28 ± 0.00, 0.93 ± 0.16% and 0.19 ± 0.00, 0.71 ± 0.00 meq/kg for PO, SO respectively. The fatty acid composition of SO showed significant change with a decrease in linoleic acid and oleic acid content from 42.7 ± 0.01 to 28.1 ± 0.03 and 36.2 ± 0.01 to 25.1 ± 0.01 after 16 frying cycles respectively. The oleic acid content of PO was less affected it decreased from an initial value of 42.4 ± 0.01 to 38.9 ± 0.01 after 16 cycles. The fatty acid composition of PO made it more stable to the repetitive frying process. The physical properties like density refractive index and viscosity of SO were badly affected by repetitive frying. The french fries fried in PO score higher overall acceptability in the sensory examination.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-023-05774-4.

Keywords: Palm oil, Sesame oil, Deep fat frying, French fries, Oxidative stability

Introduction

Deep fat frying is one of the most preferred methods of frying foods across the globe. During the frying process, food is deluged in hot oil for a required period of time, till the food gets a crispy texture. Due to the oxygen-rich environment, temperature, and presence of water from food the oxidation of the frying medium takes place leading to the formation of undesirable by-products. During deep fat frying food is exposed to a higher temperature of about 1500 to 190 °C (Waghmare et al. 2018) Deep frying process is a complex process in which oil undergoes numerous reactions resulting in the formation of oxidation by-products like hydroperoxides, aldehydes, ketones, carbonyl compounds. The common process includes hydrolysis, oxidation, and polymerization. they produce volatile and non-volatile compounds. Most of the volatile compounds evaporate in the atmosphere with steam. The process also results in changing fatty acid composition and the generation of loads of free fatty acids in the frying medium resulting in a change in the viscosity of the oil. Deep fat frying gives texture to fried food and increases its palatability of food, deep-fried foods are susceptible to a higher degree of oxidative breakdown thus reducing keeping quality/shelf-life of fried food over a period of time (Choe and Min 2007).

Palm oil is among the most commonly used oil for the deep-fat frying process due to its easy availability, affordable cost. The fatty acid composition of palm oil is 44% Palmitic acid and 5% stearic acid and unsaturated fatty acids like oleic acid is around 40% and 10% linoleic acid (Montoya et al. 2014). Palm is usually preferred for cooking purposes owing to its availability across the year and low cost. It is majorly produced in Thailand and Malaysia (Wroniak et al. 2021).

Sesame (Sesamum indicum L.) is the oldest crop in the Indian agronomy, sesame has various names like gingelly, till, simsim, and gona also called the queen of oil seeds.it belongs to the family Pedaliaceae and its scientific name is Sesamum Indicum L. India is among one of the largest producers of sesame in the world. The average production of sesame during 2018–2021 was 890,000 metric tonnes. Sesame is known for monounsaturated fatty acid (MUFA), polyunsaturated fatty acid (PUFA), proteins, and fibers. It also contains various components like phytosterols free as well as in esterified forms, phospholipids, polyphenolic compounds, lentils, etc. These components are responsible for many health benefits conferred upon the consumption of sesame. (Shi et al. 2018). Sesame seed has gained considerable attention in human nutrition mostly in formulations of functional foods since sesame seeds are a rich source of essential amino acids, essential fatty acids, tocopherols, and many other phenolic compounds including sesamol, sesamolin, phenylethanethiol,vinyl guaiacol, furyl-methanthiol, furaneol (Moazzami and Kamal-Eldin 2006). Sesame seed oil is unique as it has around 40% MUFA and 37% PUFA which are predominantly oleic acid and linoleic acid respectively. The higher PUFA in sesame oil makes its less stable for food applications like frying (Dey et al. 2018) Sesame oil is extracted from sesame seed adopting various extraction processes. Other than cooking oil, sesame oil has many applications like massage oil, and hair oil giving more nourishment to skin and hair. The sesame oil contains higher unsaturation because of which it is easily prone to oxidative degradation thus leading to the development of rancidity and decreasing the shelf-life of sesame oil and also food that is cooked/fried using sesame oil.

The present study aimed to evaluate and compare the frying performance of sesame oil and palm oil by deep-frying potato French fries. The oil used for deep frying was evaluated for its oxidative stability in terms of formation of free fatty acids, generation of primary oxidation products like hydroperoxides, change in the fatty acid profile of oil upon frying and also change in physicochemical characteristics like refractive index, viscosity, the density of fried oil was evaluated. The present study gave an idea about the effect of repetitive frying on the quality of the frying medium.

Materials

Refined palm oil and McCain French fries were procured from the retail shop in Mumbai. Cold-pressed sesame oil was collected from the local oil extraction unit, in Mumbai. All chemicals used were of analytical grade and were purchased from the S. D. fine Pvt. ltd Mumbai.

Experimental design and process of frying potato sticks

In a frying experiment, the electrically heated sand bath was used containing 2 frying baths. Approximately 800 ml of frying oil was introduced into the frying baths, the oil was heated at the temperature of 160 ± 5 °C and the temperature was kept uniform during the entire process and was monitored at regular intervals during frying. During the frying process, 40 g of potato French fries were fried for 5 min, this process was carried out four times a day at an interval of 45 min. The frying process was repeated for four days and a total of 16 frying batches were processed. After completion of the frying process, the heater was turned off and the oil was allowed to cool. After cooling this oil was filtered to remove any debris using a stainless-steel stain. The collection was stored in an airtight bottle at 4 ± 2 °C for further analysis.

Analytical methods

Density

A specific gravity bottle with a capacity of 10 ml was used for the determination of density. Each sample was analysed in triplicate.

Refractive index (RI)

RI of oils was determined using an Abbe refractometer (Guru Nanak Instruments, New Delhi). The micropipette was used to drop oil on a lower prism. Prisms were locked and with the help of a screw head, it was tightened, and allowed to stand undisturbed for about 3 min. The borderline was made sharp and colorless by adjusting the alidade nob, readings were then taken in triplicates. The prism was cleaned between measurements using soft tissue paper.

Viscosity

Viscosity was determined using the Brookfield programmable rheometer (model DV-III, Brookfield Engineering Labs, USA). Brookfield spindle and a guard were attached and studied at fixed rpm 20. The temperature was kept constant (25 ± 2 °C) throughout the experiment. Readings were recorded after 30 s of each run.

Acid value (AV)

AV of fried oil was found by the following procedure as described by Jadhav et al. (2022) with modifications. 1 gm of oil was taken in a flask and to it, 5 ml of ethanol was added followed by a phenolphthalein indicator. Titrations were performed using 0.1N KOH to the end point indicated by the appearance of pink color. AV was expressed as mg KOH/g of the sample. The %FFA was calculated as per the equation below:

Peroxide value (PV)

PV was determined as described by Waghmare et al. (2018). Approximately 5 g of sample was weighed and added to 10 ml of chloroform then 15 ml of acetic acid followed by the addition of 1 ml of saturated KI. This mixture was mixed by slowly shaking the flask in darkness for about 5 min, then 75 ml of distilled water was added. Sodium thiosulfate solution (Na2S2O3) 0.01 mol/l was used for titration. The starch solution was used as an indicator. Titration was continued till the brown colour disappeared. The following equation was used for the calculation of PV:

where V is the ml of Na2S2O3, Vb is the ml of Na2S2O3 for the blank simple (without oil), T is the normality of Na2S2O3solution and m is the mass of oil (g).

Fatty acid profile of oils

20 mg of oil sample were dissolved in 1 ml hexane and 1 ml of hexane containing 0.5 mg of C17:0 as an internal standard. 1 ml of methanol and 300 µl H2SO4 were added for transesterification which was kept at 70 ± 2 °C for an hour in hot oven. Just after completion of transesterification process the mixture was cooled at 25 ± 2 °C. 1 ml of deionised water was added to remove out residual CH3OH and H2SO4. Sample was allowed to rest, to allow maximum separation of two layers. Upper organic phase was collected using pipette and filter through 0.2 µm syringe filter. Gas chromatography equipped with flame ionization detector (GC-FID) (Agilent Technologies 7820A). A DB-23 capillary column (30 m × 0.250 mm id., film thickness 0.25 micron) was used for analysis of fatty acid composition. The oven temperature was held for 10 min at 100 °C and subsequently increased to 240 °C at 4 °C/min. Each FAME peak was identified and quantified by referring a 37 component FAME standard mix (Supelco®, Bellefonte, USA).

Texture analysis

A texture analyser (TA-XT2i, Stable Micro System Co. Ltd., Surrey, UK) was used to evaluate the texture of the French fries samples fried in PO and SO. Probe (P/2) was used for applying force on the sample placed on the platform. Test conditions were maintained as pre-test speed (10 mm/s), test-speed (10 mm/s), and post-test speed (10 mm/s) and 2 mm was the deformation distance. A curve of force against time was analysed using the software. Texture expert exceed version 2.64 (Stable Micro Systems, Ltd.) associated with the texture analyser. The parameter used to describe texture of sample were hardness.

Sensory analysis

Sensory analysis of fried french fries was done by 10 trained members from department of food engineering and technology, ICT, Mumbai. The product was evaluated on the hedonic scale from 1 to 9, where 1 represents poor and 9 represents excellent. Various sensory parameters like colour, taste, crunchiness, oiliness and overall acceptability were evaluated for French fries fried in palm and sesame oil.

Statistical analysis

All the experiments reported and discussed in result and discussion section was done in triplicate to evaluate the replicability of the experiments. The results are reported as mean ± standard deviations of 3 individual experiments.

Results and discussion

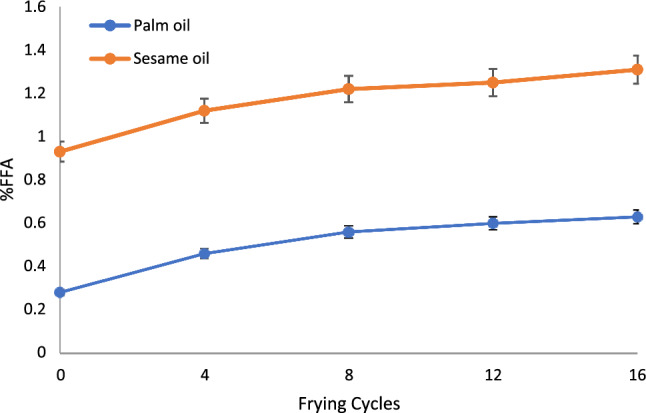

Effect of repetitive frying on FFA content

FFA are considered as an indicator of onset of rancidity in oil used for food applications. The formation of FFA results in generation of undesirable flavour in frying medium and fried food. The change in FFA content in palm oil (PO) and sesame oil (SO) after repetitive frying is shown in Fig. 1. The FFA content for both the frying medium increases with increase in the frying cycle. The observed FFA content in PO was 0.28 ± 0.00, 0.46 ± 0.16, 0.56 ± 0.00, 0.60 ± 0.16, 0.63 ± 0.12% after 0, 4, 8, 12, 16 frying cycles respectively. The initial FFA content of 0.28 ± 0.00 increased to 0.63 ± 0.12 repetitive frying of palm oil. Similar trend was also observed in SO, the FFA content in SO increased from 0.93 ± 0.16 to 1.31 ± 0.16% after 0 and 16 frying cycles respectively. The FFA content increased in both the frying medium, however the increase in FFA content was higher in SO frying medium in comparison with PO frying medium. The increase in FFA content of frying medium could be due to hydrolysis of triglycerides releasing free fatty acid in the frying medium. The migration of water from food into the frying medium during frying brings about the hydrolysis of triglycerides, thus increasing the FFA content in the frying medium. The SO contains higher unsaturation as compared to PO, thus the oxidation of double bond results in formation of oxidative by-products which are further oxidized to fatty acid with lower molecular weight, thereby increasing the FFA content in SO frying medium. Debnath et al. (2012) studied effect of repetitive frying on the physicochemical qualities of rice bran oil. The authors reported that the FFA content of the frying medium increased with the successive frying of oil, the FFA increased from initial value of 0.15% to 0.48% after six frying cycles. Similarly, Jadhav et al. (2022) also reported increase in the FFA content with increase in the frying cycle for palm olein and structured palm olein. The increase in the FFA content in PO and SO in present work is in line with the data available in the literature. The presence of higher unsaturation results in higher degradation of frying medium, indicating PO to be comparatively more stable than SO in repetitive frying operations.

Fig. 1.

Changes in FFA content of PO and SO with successive frying cycles

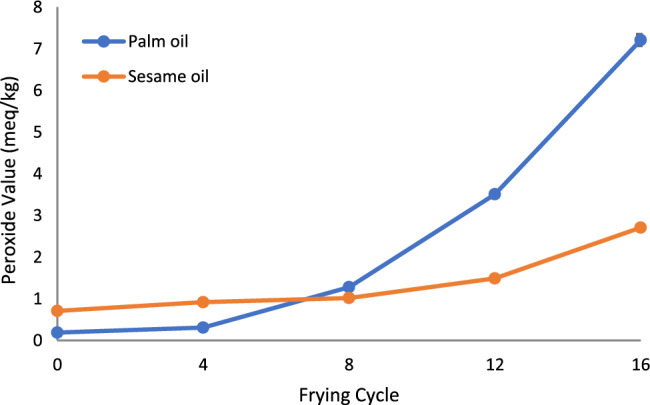

Effect of repetitive frying on Poxide value (PV)

The primary oxidation in oil is better indicated by the PV. Peroxides are primary oxidation products formed in the initial stages of lipid oxidation. The change in the PV of PO and SO is represented in Fig. 2. The PV of SO increased as 0.19 ± 0.00, 0.31 ± 0.01, 1.28 ± 0.01, 3.51 ± 0.00, 7.21 ± 0.01 meq/kg after 0,4,8,12,16 frying cycles. Similarly, the PV of PO increased from 0.71 ± 0.00 to 2.71 ± 0.02 after 16 frying cycles. The PV of SO showed higher increase in comparison with the PV of PO for repetitive frying of French fries. The SO showed higher oxidative deterioration as indicated by higher PV. The SO was badly affected due to oxidation as there were higher peroxides reported in SO. The PV of PO and SO increased with increase in the frying cycle however the PV was below 10 meq/kg (El-Rahman et al. 2006), indicating that it was still suitable for frying operation after 16 cycles. The higher PV of SO is attributed to its higher unsaturation; the unsaturated fatty acids are highly prone to oxidative deterioration. The factors like higher frying temperature, migration of food constituents from food into frying medium, moisture content of food resulted in accelerating the oxidative deterioration of frying medium. PO contains saturated fatty acid, monounsaturated fatty acid in higher proportion which are comparatively more stable to oxidative damage, thus the PV of PO was within the limit even after 16 frying cycles, making it a good choice for frying operation in comparison with the SO. Jadhav et al. (2022) studied oxidative stability of palm olein blend after repetitive frying of food. The authors reported increase in PV with successive frying but within limit (10 meq/kg), i.e., the PV of frying blend containing higher palm oil increased from 1.38 ± 0.01 to 1.94 ± 0.02 after 0 and 48 frying cycles respectively. Hence, PO shows higher oxidative stability during deep frying of food and even after repetitive frying operation the PV increases but remains within limit.

Fig. 2.

Changes in peroxide value of PO and SO with successive frying cycles

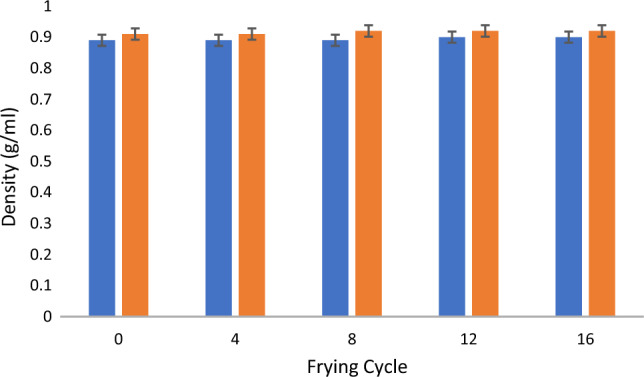

Effect of repetitive frying on density, refractive index (RI) and viscosity of frying medium

The density of the frying medium is a crucial parameter since a change in density affects the rate of heat transfer during the frying process. Ideally, density of the frying medium should remain constant after successive frying of foods in it (Paul and Mittal 1995). The data obtained in the present work is shown in Fig. 3. The density of PO showed a slight increase after 8 frying cycles and the density of PO increased from 0.89 ± 0.00 g/ml (up to 8 frying cycles) to 0.90 ± 0.00 g/ml and 0.91 ± 0.01 g/ml after 12 and 16 frying cycles respectively whereas the density of SO changed after 4 frying cycles and then remain constant up to 16 frying cycles. The density of SO was 0.91 ± 0.01, 0.91 ± 0.01, 0.92 ± 0.00, 0.92 ± 0.00 and 0.92 ± 0.01 g/ml after 0.4.8.12.and 16 frying cycles respectively.

Fig. 3.

Effect of successive frying cycle on the density of PO and SO

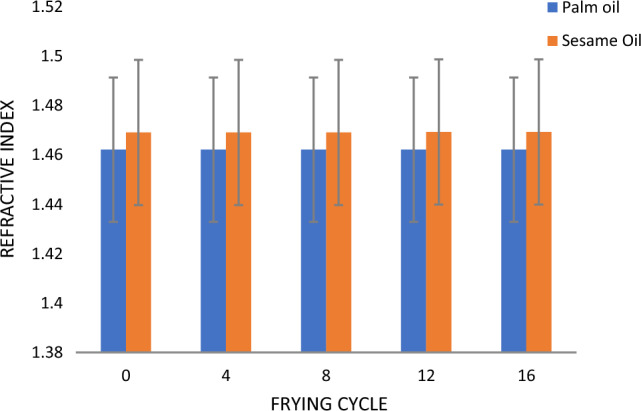

The RI is closely related to the fatty acid composition of triglycerides and their chain length. The RI of SO showed slight changes after 8 frying cycles as seen from Fig. 4. The RI of SO increased from 1.4691 ± 0.001 to 1.4693 ± 0.000 after 8 frying cycles and then remained constant up to 16 frying cycles. However, the RI of PO did not change up to 16 frying cycles, the RI was 1.4621 ± 0.001 till 16 frying cycles. The results obtained in the present study are in line with the data reported by Waghmare et al. (2018). The authors reported no change in the RI of PO even after 4 frying cycles whereas the RI of sunflower showed a slight increase from 1.470 to 1.473 after 4 frying cycles. The unsaturation and chain length of fatty acid present in the frying medium resulted in a change in RI. In the present case SO contains polyunsaturated fatty acids having higher chain length as compared with saturated and monounsaturated fatty acids found in PO. Hence, the RI of SO should slight changes and PO remained constant after successive frying for 16 cycles.

Fig. 4.

Effect of successive frying on refractive index of PO and SO

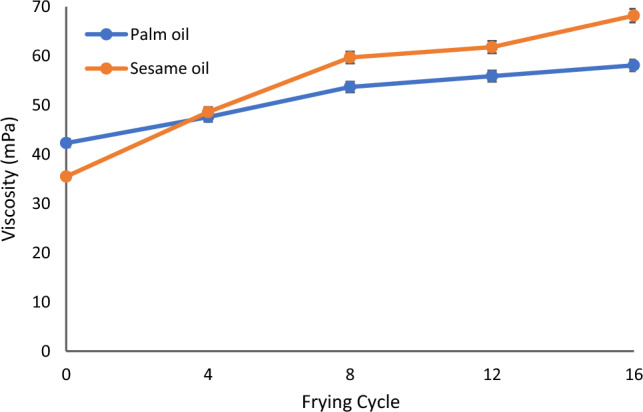

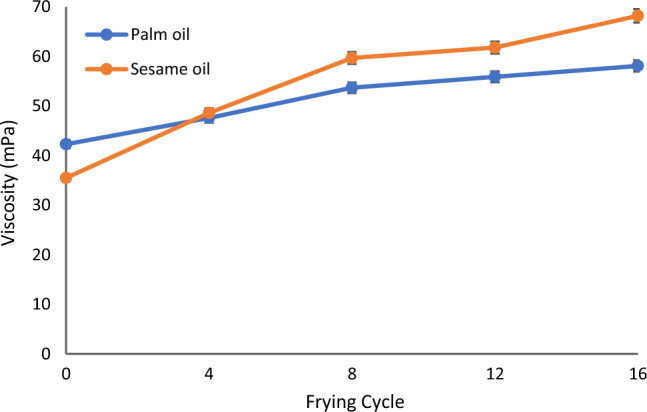

Viscosity of the frying medium is important as it affects the frying process and flowability of oil. The changes in the viscosity of PO and SO frying medium are represented in Fig. 5. The initial viscosity of PO and SO was 42.3 ± 2.07 mPa and 35.5 ± 2.37 mPa respectively. The viscosity of both the frying medium increased with the successive frying cycles. The viscosity of SO increased as 35.5 ± 2.37, 48.6 ± 3.07, 59.7 ± 3.09, 61.8 ± 2.25, 68.2 ± 2.70 mPa after 0,4,8,12,16 frying cycles. The viscosity of PO also showed an increasing trend as 42.3 ± 2.07, 47.6 ± 2.27, 53.7 ± 2.94, 55.9 ± 2.95, 58.1 ± 1.66 mPa after 0,4,8,12,16 frying cycles. The repetitive frying process affected the viscosity of both the frying medium however viscosity of SO was largely affected as evident from the obtained results. The migration of water from the fried food into the frying medium resulted in the polymerization of the frying medium and the process of repetitive frying resulted in the formation of polymeric compounds having higher molecular weight as a result of the polymerization reaction during frying. These compounds started accumulating in the frying medium as the frying cycle increased which resulted in an increase in the viscosity of the frying medium. The frying medium becomes more viscous with successive frying cycles and with increase in the viscosity of frying medium the rate of heat transfer decreases, which results in longer exposure of food to the frying medium and higher absorption of oil in food. Zubairi et al. (2022) reported the effect of repetitive frying on the viscosity of palm oil as a frying medium. The authors reported that the viscosity of palm oil exceeded the value of 38.6 Cp after successive frying of 15 cycles. A similar increase in viscosity with an increase in frying cycles was also reported by Jadhav et al. (2022), Waghmare et al. (2018), (Debnath et al. 2012). The results obtained in the present study are in accordance with the studies reported in the literature.

Fig. 5.

Changes in viscosity of PO and SO with increase in frying cycle

Effect of repetitive frying on the texture of food:

The texture of food is very important to attract consumers and should be eye appealing. Textural characteristics in terms of hardness were determined and the obtained results are shown in Fig. 6. Hardness was determined by applying force in Newton on the French fries. Maximum peak force was recorded as the hardness of French fries in Newton. As seen in Fig. 6, the hardness of French fries decreased with an increase in the frying cycle when fried in SO. The maximum hardness of French fries was retained when fried using PO. This may be because of lower damage to the triglycerides and fatty acids present in PO as compared with the SO where maximum oxidative deterioration was caused due to successive frying at a higher temperature. As the frying cycle increases, there is an accumulation of more oxidation by-products in the frying medium which negatively affects the rate of heat transfer which in turn increases frying time and food is not properly fried in such oil, thus the hardness of fried food is affected. The lower degree of oxidative deterioration in PO turned out to be beneficial in maintaining the hardness of French fries till the 16-frying cycle. The present study showed that the frying medium has a remarkable impact on maintaining the texture of fried food in a repetitive deep-fat frying process.

Fig. 6.

Changes in texture (hardness) of french fries subjected to deep frying in PO and SO

Sensory examination

Sensory attributes like color, taste, crunchiness, oiliness, and overall acceptability were evaluated for French fries fried in PO and SO. The changes in sensory attributes with repetitive frying are shown in supplementary files S1 and S2 for PO and SO respectively. Color is an important parameter that can be seen and should be appealing. The French fries fried during the first frying cycle in PO and SO appeared to be light yellow in color and there was a change in the color of the French fries as the frying cycle increased. The score for the color of French fries fried in SO and PO decreased after 4 and 12 frying cycles respectively. The decrease in color could be because of the darkening of the frying medium causing change in the color of fried food. The French fries fried in PO showed superior taste as compared with French fries fried in SO as indicated by the score given by the panel members. Crunchiness is an important sensory parameter for French fries. French fries fried in PO scored a higher score for crunchiness. The crunchiness of the French fries fried in SO showed a decrease with the increase in the frying cycle which is also in agreement with the results obtained for hardness. The French fries fried in PO were preferred by the panel members even after 16 frying cycles and obtained a maximum score for crunchiness. Oiliness refers to oil absorbed in French fries; it can easily be felt by just pressing the French fries. The French fries which had less absorbed oil scored higher sensory scores for oiliness. French fries fried in PO were highly preferred by the panel members in terms of oil absorption. SO fried French fries score low score after 4 frying cycles as they had a higher percentage of absorbed oil. The accumulation of oxidation by-products resulted in a decrease in heat transfer rate, thus frying time and oil uptake in food increased in the case of SO, which is in line with the results obtained for viscosity. The overall acceptability of French fries fried in PO was much higher than that of SO. The obtained results in the present work suggested that frying of French fries in PO retained all important sensory attributes even after 16 frying cycles which were not observed in SO.

Fatty acid composition

The change in the fatty acid content of PO and SO with successive frying is shown in the Supplementary file (S3). There was a change in the fatty acid composition of both frying oils upon successive frying. The saturated fatty acid content increased in both the frying medium. The initial concentration of palmitic acid was higher in PO i.e., 44.1 ± 0.01% which increased to 48.3 ± 0.00% after 16 frying cycles whereas stearic acid increased to 10.3 ± 0.01% from 5.3 ± 0.01% after 16 frying cycles. The percentage of unsaturated fatty acid decreased in PO, the linoleic and linolenic acid decreased to 1.2 ± 0.00% and 0.91 ± 0.01% from 4.8 ± 0.02% and 3.1 ± 0.00% after 16 frying cycles. A similar trend was seen in SO with an increase in the frying cycle, there was an increase in the percentage of palmitic and stearic acid from 10.3 ± 0.00% and 4.6 ± 0.00% to 25.9 ± 0.01% and 17.6 ± 0.01% after 16 frying cycles whereas linoleic acid decreased from 42.7 ± 0.02% to 28.1 ± 0.01% after 16 frying cycles. Similarly, the percentage of oleic acid decreased in both SO and PO frying medium with successive frying. The polyunsaturated fatty acid present in SO was badly affected by the frying process. It is observed that the fatty acid containing unsaturation is more prone to oxidative deterioration during the process of frying due to the existence of π-bonds which results in the formation of degradation products. The PO is more stable for the repetitive frying process owing to its fatty acid composition in comparison with the SO, which degrades faster and makes the frying medium unsuitable for successive frying of food.

Conclusion

The current work reported a comprehensive study concerning the effect of repetitive frying on the quality of palm oil and sesame oil. Changes in physicochemical properties were studied to understand the effect of repetitive frying on the quality of the frying medium. It was observed that palm oil as a frying medium was more stable to oxidative deterioration during repetitive deep frying of French fries as compared with sesame oil for 16 frying cycles. The FFA content and PV of PO and SO was 0.63 ± 0.12, 1.31 ± 0.16% and 2.71 ± 0.02, 7.21 ± 0.01 meq/kg respectively after 16 frying cycles. The density, RI and viscosity was also adversely affected due to repetitive frying in case of SO and was little affected in case of PO. The viscosity after 16 frying cycles for PO and SO was 58.1 ± 1.66 and 68.2 ± 2.70 mPa respectively. Increase in viscosity of SO resulted in increases of frying time and affected texture of French fries. The hardness of French fries fried in SO decreased whereas hardness of french fries was maintained when fried in PO during repetitive frying. The successive frying process changed the fatty acid composition of PO marginally and changes were significant in SO, the percentage of saturated fatty acid increased and unsaturated fatty acid decreased. The french fries fried in PO was preferred by the sensory panel members over french fries fried in SO. The oiliness, taste, and crunchiness of french fries fried in SO were badly affected. The overall sensory acceptability score of PO was much higher than SO. Thus, palm oil was a good frying medium for repetitive deep frying of french fries as compared with sesame oil. Palm oil can be used for repetitive frying operations without much damage to its physicochemical characteristics.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

The author would like to acknowledge the Department of Food Engineering and Technology, ICT Mumbai for providing a research facility.

Author contributions

PS: Conceived and designed the analysis data collection, performed the analysis, contributed data, data analysis, interpretation of data, manuscript writing, UA: critical revision of the article, supervision and final approval for the publication.

Funding

Not applicable.

Data availability

The datasets generated during the current study are available from the corresponding author upon reasonable request.

Code availability

Not applicable.

Declarations

Conflict of interest

There is No conflict of interest among the authors.

Ethical approval

Not applicable.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Choe E, Min DB. Chemistry of deep-fat frying oils. J Food Sci. 2007;72(5):R77–R86. doi: 10.1111/j.1750-3841.2007.00352.x. [DOI] [PubMed] [Google Scholar]

- Debnath S, Rastogi NK, Gopala Krishna AG, Lokesh BR. Effect of frying cycles on physical, chemical and heat transfer quality of rice bran oil during deep-fat frying of poori: an Indian traditional fried food. Food Bioprod Process. 2012;90(2):249–256. doi: 10.1016/j.fbp.2011.05.001. [DOI] [Google Scholar]

- Dey TK, Banerjee P, Chatterjee R, Dhar P. Designing of ω-3 PUFA enriched biocompatible nanoemulsion with sesame protein isolate as a natural surfactant: focus on enhanced shelf-life stability and biocompatibility. Colloids Surf A. 2018;538:36–44. doi: 10.1016/j.colsurfa.2017.10.066. [DOI] [Google Scholar]

- El-Rahman A, Sulieman M, El-Makhzangy A, Ramadan MF. Antiradical performance and physicochemical characteristics of vegetable oils upon frying of french fries: a preliminary comparative study. J Food Lipids. 2006;13(3):259–276. doi: 10.1111/j.1745-4522.2006.00050.x. [DOI] [Google Scholar]

- Jadhav HB, Gogate PR, Waghmare JT, Annapure US. Comparative assessment of thermo-oxidative stability of palm oil designer lipid and palm oil blends as frying medium. Appl Food Res. 2022;2(1):100039. doi: 10.1016/j.afres.2021.100039. [DOI] [Google Scholar]

- Moazzami AA, Kamal-Eldin A. Sesame seed is a rich source of dietary lignans. JAOCS J Am Oil Chem Soc. 2006;83(8):719–723. doi: 10.1007/s11746-006-5029-7. [DOI] [Google Scholar]

- Montoya C, Cochard B, Flori A, Cros D, Lopes R, Cuellar T, Espeout S, Syaputra I, Villeneuve P, Pina M, Ritter E, Leroy T, Billotte N. Genetic architecture of palm oil fatty acid composition in cultivated oil palm (Elaeis guineensis Jacq.) compared to its wild relative E. oleifera (H.B.K) Cortés. PLoS ONE. 2014 doi: 10.1371/journal.pone.0095412. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Paul S, Mittal GS. Dynamics of fat/oil degradation during frying based on optical properties. J Food Engg. 1996;30:389–403. doi: 10.1016/S0260-8774(96)00020-9. [DOI] [Google Scholar]

- Shi LK, Zheng L, Mao JH, Zhao CW, Huang JH, Liu RJ, Chang M, Jin QZ, Wang XG. Effects of the variety and oil extraction method on the quality, fatty acid composition and antioxidant capacity of Torreya grandis kernel oils. LWT Food Sci Technol. 2018;91:398–405. doi: 10.1016/j.lwt.2018.01.080. [DOI] [Google Scholar]

- Waghmare A, Patil S, LeBlanc JG, Sonawane S, Arya SS. Comparative assessment of algal oil with other vegetable oils for deep frying. Algal Res. 2018;31:99–106. doi: 10.1016/j.algal.2018.01.019. [DOI] [Google Scholar]

- Wroniak M, Raczyk M, Kruszewski B, Symoniuk E, Dach D. Effect of deep frying of potatoes and tofu on thermo-oxidative changes of cold pressed rapeseed oil, cold pressed high oleic rapeseed oil and palm olein. Antioxidants. 2021 doi: 10.3390/antiox10101637. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zubairi SI, Kadir IAA, Nurzahim Z, Lazim A. Evaluation of poly(L-lactic acid) (PLLA) rapid indicator film on deterioration degree of refined, bleached and deodorised malaysian tenera palm olein oil (RBDPO) during long-term repetitive deep-fat frying. Arab J Chem. 2022;15(4):103726. doi: 10.1016/j.arabjc.2022.103726. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

The datasets generated during the current study are available from the corresponding author upon reasonable request.

Not applicable.