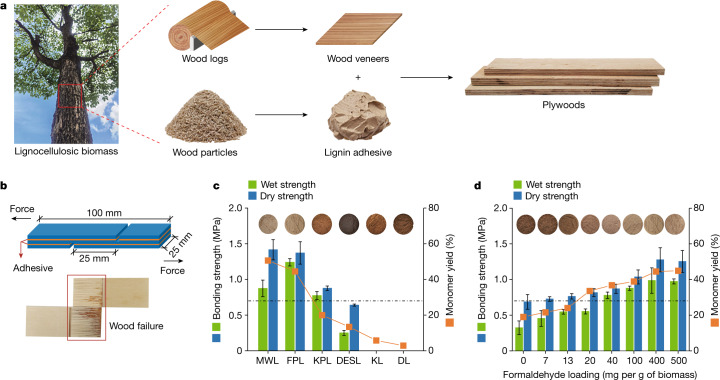

Fig. 1. Adhesion performance of adhesives prepared from different lignins.

a, Schematic illustration of preparation of plywood from wood veneers with lignins as adhesives. b, Schematic illustration of three-layer FPL-bonded plywood specimens used for adhesion performance tests (top) and wood failure of the specimen after a wet strength test (bottom). c, Adhesion performance of adhesives prepared from lignins isolated with different methods (KPL, acetone-protected lignin; DESL, deep eutectic solvent-extracted lignin; KL, kraft lignin; DL, dioxane–HCl lignin). Lignin adhesive preparation: 1:2 (w/w) lignin/water, pH 7; hot-pressing conditions: 190 °C, 8 min, 1.5 MPa and a glue application level of 100 g m−2. d, Effects of condensation degrees of FPLs on their adhesion performances. Lignin adhesive preparation: 1:2 (w/w) lignin/water, pH 7; hot-pressing conditions: 170 °C, 8 min, 1.5 MPa and a glue application level of 100 g m−2. The dot-dashed line at 0.7 MPa in c,d marks the minimum industrial requirement for the adhesion strength. All sample preparation and testing procedures as well as data calculation are described in the Methods. All examined bonding strengths were found to be significantly (analysis of variance (ANOVA), P < 0.01) affected by the condensation degree (or hydrogenolysis monomer yields) of lignins (Extended Data Table 1). Error bars show the s.d. of measured bonding strengths with four repeats.