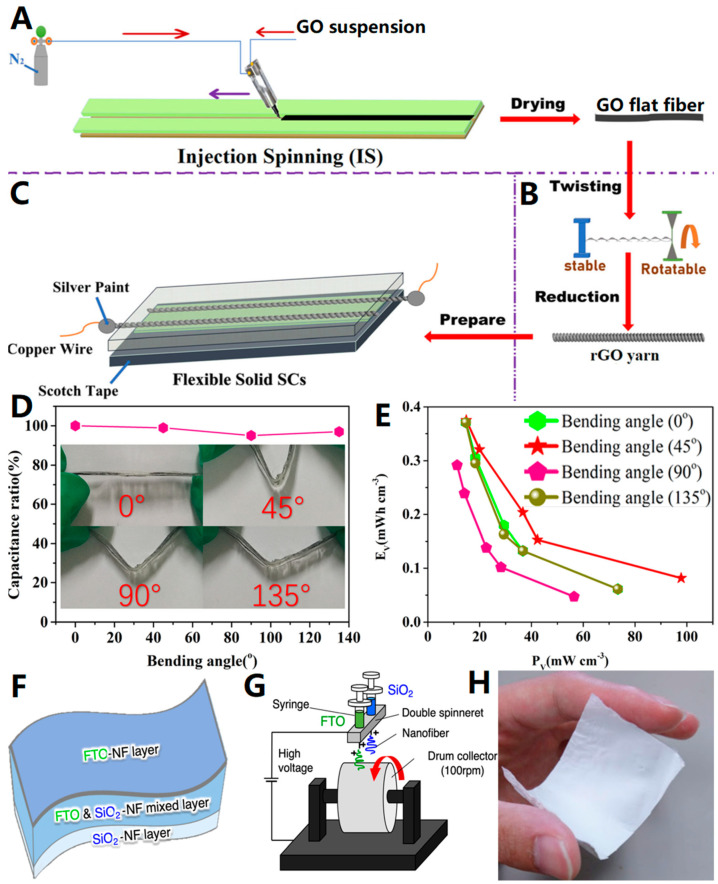

Figure 4.

(A–C) Schematic illustration of the preparation process of rGO yarns and SCs. Where (A) is a diagram of the IS for preparing GO flat fibers. (B) Twisted and reduced. (C) Instructions for Flexible Solid SCs (GFSCs) preparation. (D) Capacitance change of SC under different bending angles (0°, 45°, 90°, 135°), and (E) Relationship between energy density and power density. It could be seen that the SC has an energy density as high as 0.37 mWh cm−3 and a power density of 14.7 mW cm−3 when the bending angle is 45° [41]. Copyright 2020, Springer Nature. (F) To overcome the brittleness of FTO-NF fabrics, a three-layer structure of FTO-SiO2 composite NF nonwovens was prepared. The bottom was a support layer composed of amorphous SiO2 NFs; the intermediate layer composed of FTO-SiO2 composite NFs was mainly responsible for electrical conduction; the top was the electrical contact layer; and the surface electrodes were only made of FTO-NFs. (G) Arrangement of a double spinneret and a rotating drum collector. (H) Photo of a prepared FTO-SiO2 composite NF fabric (thickness is about 220 μm) [42]. Copyright 2021, Springer Nature.